32

Assembly

7.2.1 Hub ange / Adapter

FortheinstallationofthecontrolheadType8681toaprocessvalve(spindle),youwillrequireaprocess

valve-specichubangeasanadapter.

Thehubangemustbeadaptedtothedesignoftheprocessvalveandproducethemechanicalcon-

nection between the process valve and the control head. The axial fastening is done by two locking screws

(shoulderscrewsM5),whichengageinthemiddlegrooveofthehubange(protectionagainstpullingo).

The control head can radially slide into any position in 360° arc, seamlessly.

Thehubangeandthenon-ferromagnetic piston rod with the ferromagnetic target, which serves to

detecttheprocessvalvepositionmustcomplywiththespecicationsregardingmaterialanddimensional

accuracy – see chapter “6.7Positionmeasuringsystemdata”.

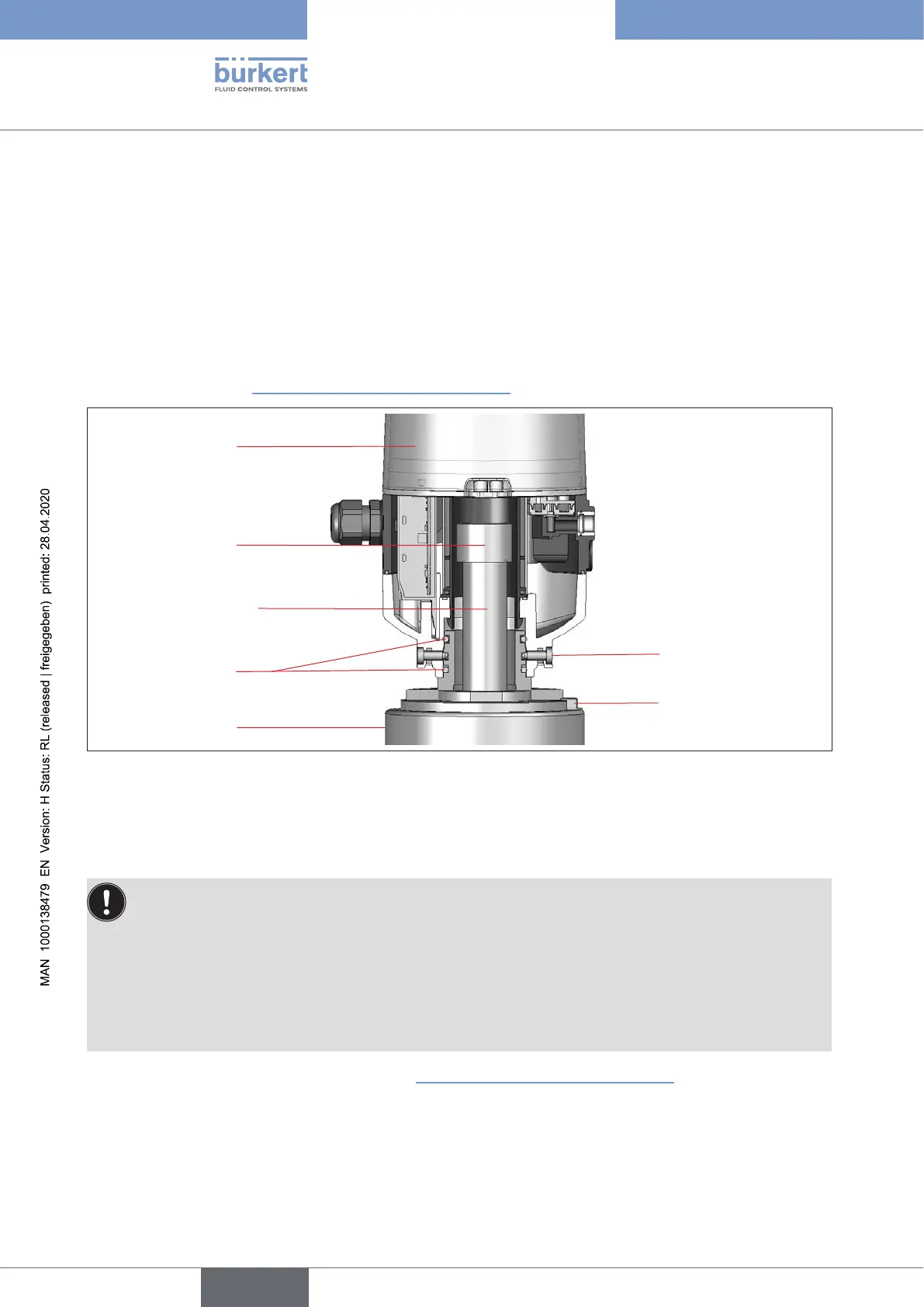

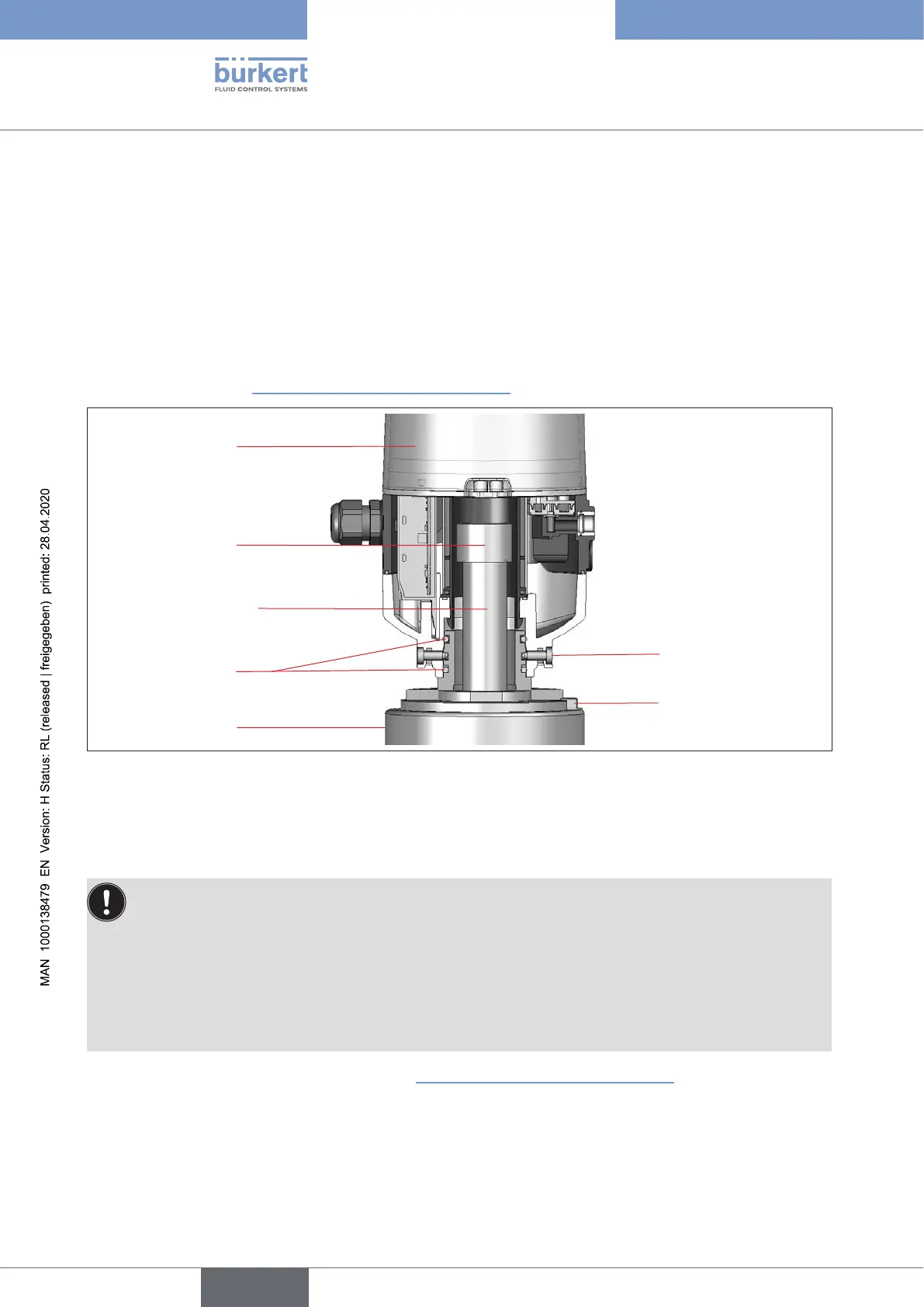

Control head

Process valve

Target made

of 1.4021

O-rings

Hubange

Locking screws

(2xM5)

Piston rod (*)

(max.Ø30)

Fig. 10: Schematic diagram of the control head - process valve adaptation

(*) The fastening materials for target and piston rod as well as the piston rod itself shall not be made of

materialwithverygoodelectricalconductivity(e.g.copper,aluminum)orofferromagneticmaterial.

Stainlesssteelwithoutferromagneticpropertiesissuitable(ifnecessary,checkaftermachining).

•To ensure the proper function of the position measuring system, the axial deviation of the adapter

must be less than ± 0.1 mm to the spindle when mounted!

•

UseBürkertadaptionsexclusively.

•Priortoassemblingthecontrolheadontothehubange,lightlygreasetheO-ringswithasilicone

grease.

•The hood must be lead-sealed in the potentially explosive atmosphere to prevent the housing

from being opened without a tool!

For dimensional relationships, see also chapter

“6.7Positionmeasuringsystemdata”.

english

Control Head Type 8681

Loading...

Loading...