THS – FI022GB2K8v3 --- V - MAINTENANCE

85

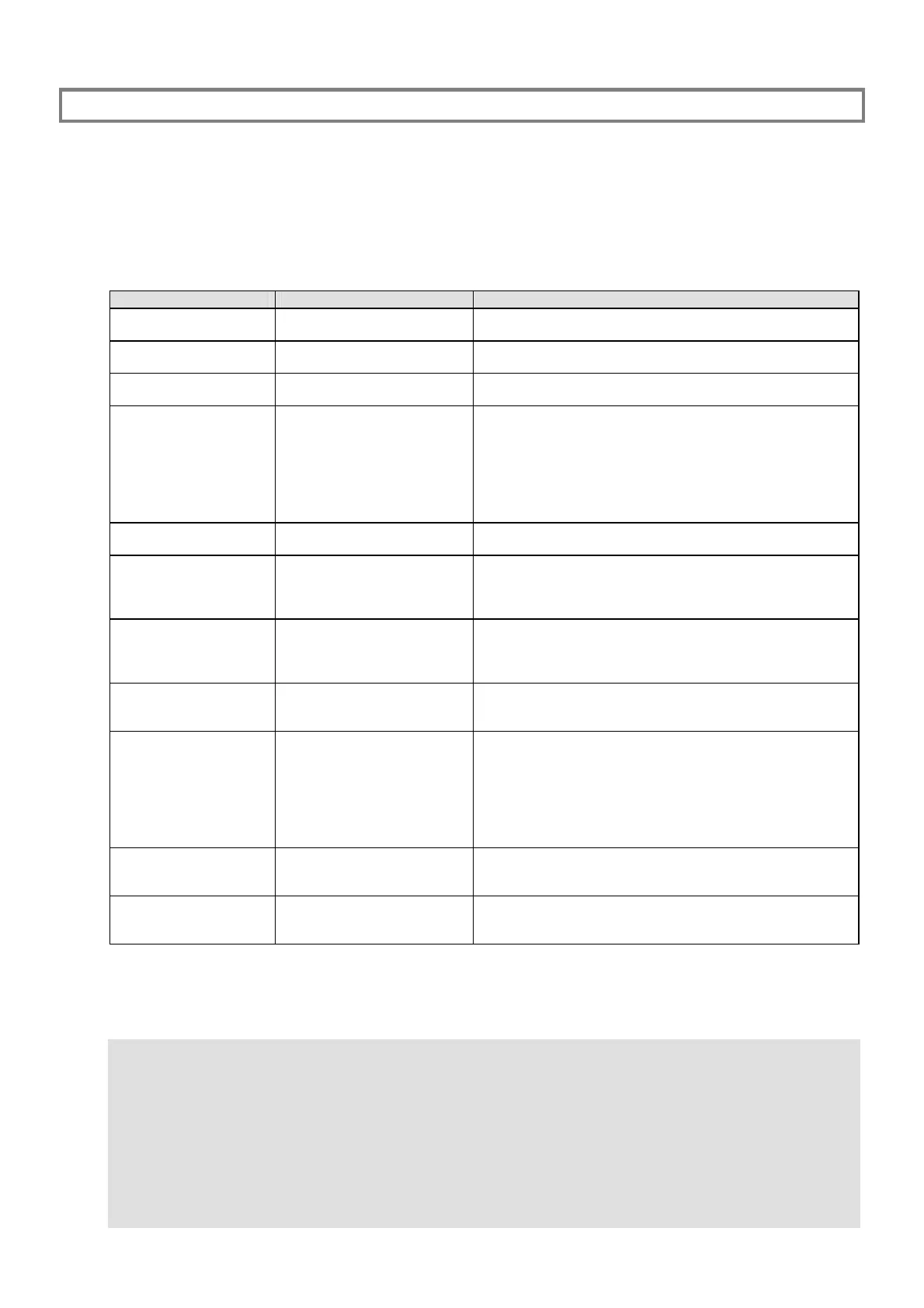

Self-diagnosis

The internal diagnostic system monitors the operational status of the metal detector. If a fault is detected, the following

are activated in addition to a message on the display:

• the illuminating alarm indicators

• the buzzer (if activated)

• the fault relay (if Fault relays parameter is ON)

• flashing light (if Fault relays parameter is ON)

Fault status can only be reset by eliminating the cause of the fault.

Table V-2

Message Probable cause Action

Test time out Time-out for pre-programmed

test.

Carry out the test

Fault: power Power-supply section faulty

Contact service technician

Fault: probe Antenna connection broken

Contact service technician

Fault: ejection ** Ejection of material not

carried out

• Check that the ejection times are correct.

• Check that the ejector is not blocked

• Check photocell operation (positioning, connections

etc.)

• Check the Confirm Ejection input connections

When the cause of the fault has been eliminated, press the

E key to reset the alarm status.

Bin full Storage container full Empty it

Press E key to reset the alarm status

Fault: communication Fault in communication

between SCD and ALM cards

Check that the power-supply voltage is stable and

corresponds to the values on the identification plate.

Check the wiring

If the wiring is correct, replace the cards

Fault: motor alarm

("motor alarm" indicator

activated)

Overloading of the belt motor

Wrong setting of CU

parameter

Remove the cause of overloading and press E key.

Set a proper value of CU parameter and press E key.

Fault: air pressure Compressed air pressure too

low

Check the compressed air connection.

When the cause of the fault has been eliminated, press the

E key

Photocell fault *** Photocell malfunction or pack

stuck in front of photocell

• check there is no pack stuck in front of the photocell

• check the photocell connections

• Check the positions of the photocell and the

retroreflector

• replace the photocell

When the cause of the fault has been eliminated, press the

E key to reset the alarm status ****

Memory card not

installed (THS system

not operative)

Memory faulty or absent Check presence and connections of the SPM external

memory card (see para. "Replacement of SCD card"

Compatibility error SCD card incompatible with

the data stored in the SPM

memory card

Use compatible SCD card (ask service personnel)

*Enabled by the Fault relays parameter

**Enabled by the Ejection confirmation parameter

*** Enable via the PHOTO Alarm parameter

**** The self-diagnosis message may appear:

- in the case of a conveyor belt without encoder or with Power Control Box, with the belt stopped or moving

- in the case of a conveyor belt without encoder or with Conveyor Control System, with the belt moving

The system is not designed to signal a pack which is stuck for some reason in front of the photocell. For this

reason, when the system can detect whether or not the conveyor belt is moving (i.e. when it is equipped with an

encoder or with the Conveyor Control System power supply unit), the self-diagnosis function gives an alarm only if

the photocell is in a state of malfunction when the belt is moving.

On systems without encoder or with the Control Power Box, it is the installer’s and operator’s responsibility to

ensure that material does not remain in front of the photocell when the belt is stopped: if it does, the photocell

will be continuously active even though it is not malfunctioning. If the foregoing situation can not be avoided, it is

advisable to disable photocell self-diagnosis (Parameter PA)

Loading...

Loading...