M-Series Operator’s Manual 4/9/15

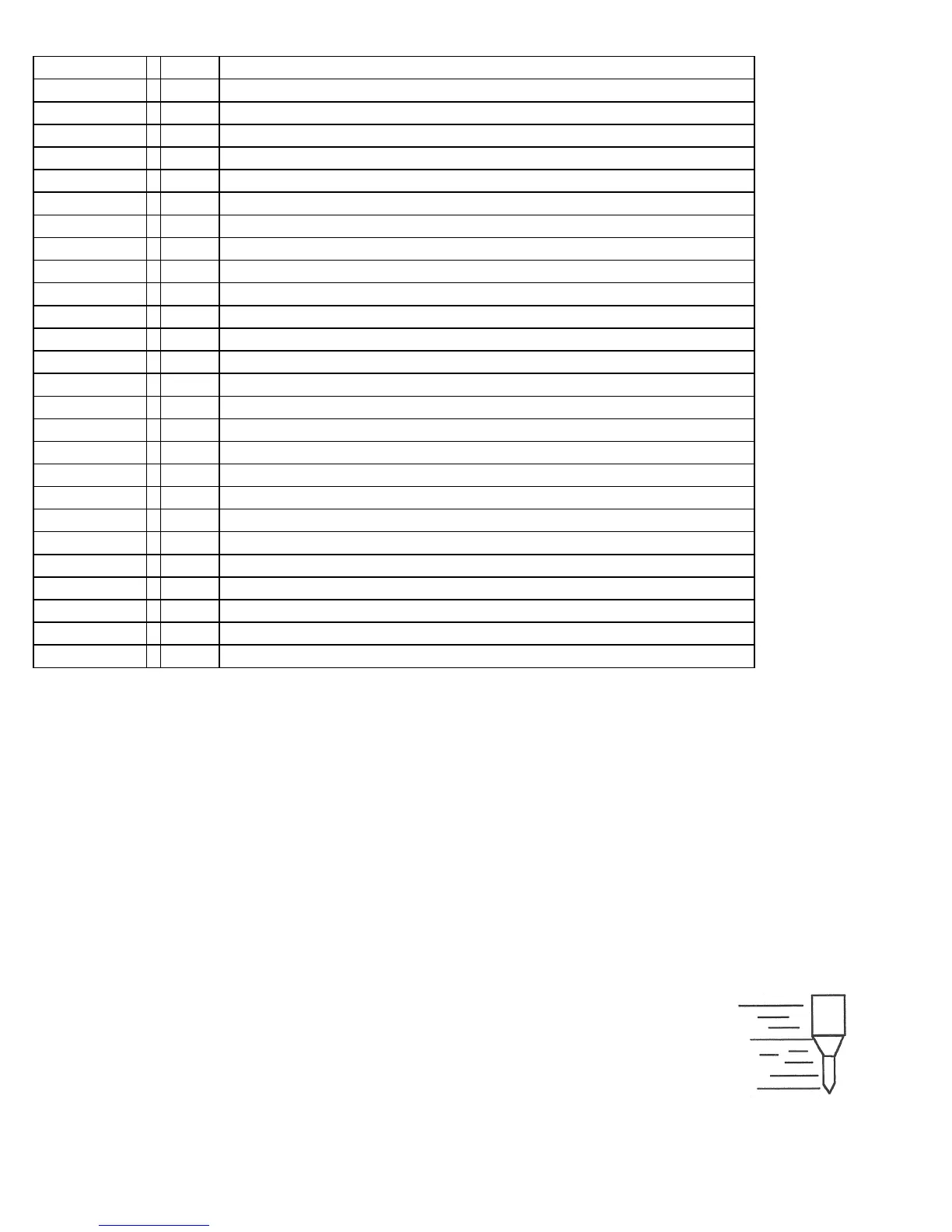

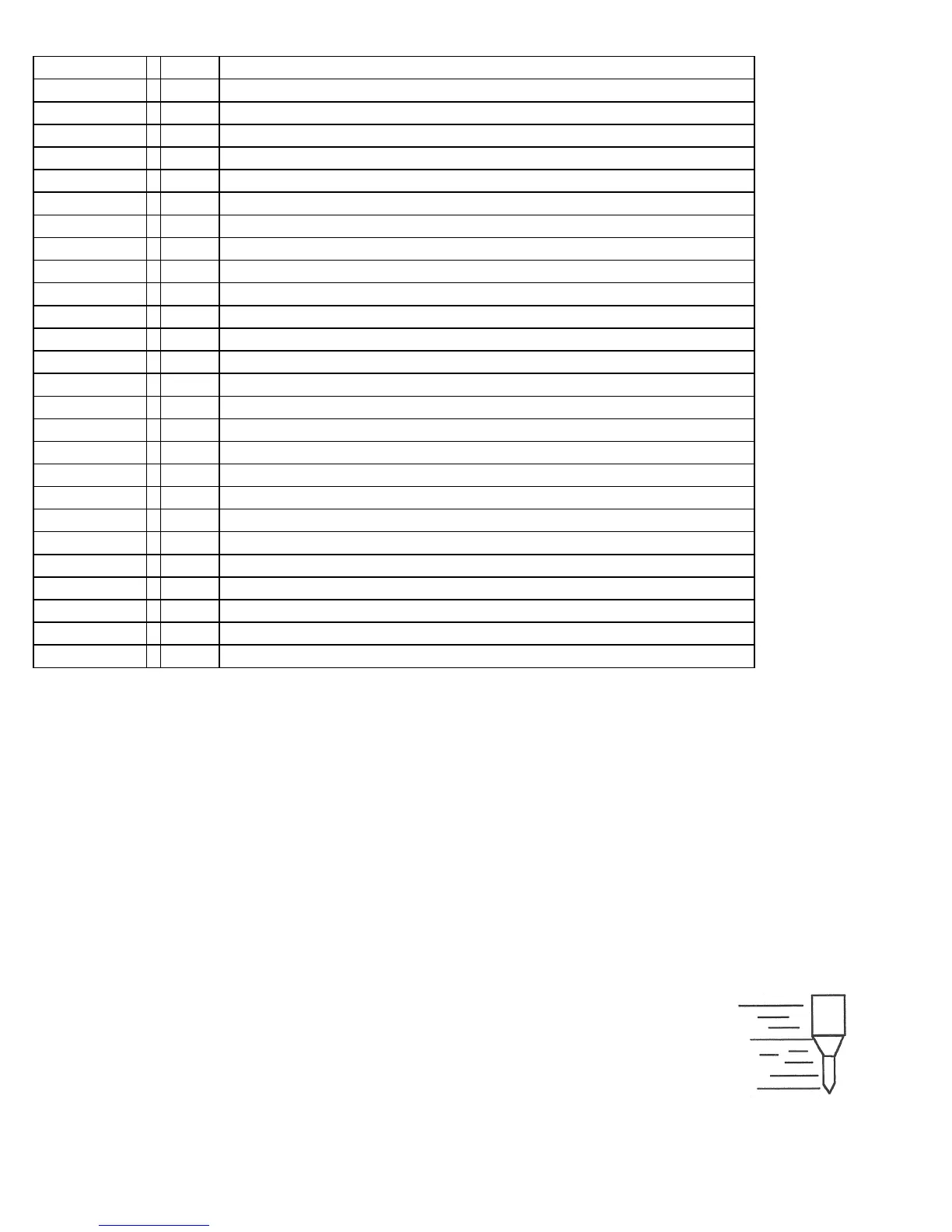

G81

G Drilling and Spot Drilling

G82

G Drill with Dwell

G83

G Deep Hole Drilling

G84

G Tapping

G85

G Boring

G89

G Boring with Dwell

G90 *

H Absolute Positioning Mode

G91

H Incremental positioning Mode

G92

B Set Absolute position

G93

P Inverse Time On

G93.1

P Velocity Scrubber for Smoothed Inverse Time Data

G94

P Inverse Time Off

G98 *

I Initial Point Return

G99

I R Point Return

G117

C Rotation of Plane Selection XY

G118

C Rotation of Plane Selection ZX

G119

C Rotation of Plane Selection YZ

G173

G Compound High Speed Peck Drilling

G174

G Compound Counter Tapping

G176

G Compound Fine Bore Cycle

G180

G Compound Canned Cycle Cancel

G181

G Compound Drilling and Spot Drilling

G182

G Compound Drill with Dwell

G183

G Compound Deep Hole Drilling

G184

G Compound Tapping

G185

G Compound Boring

G189

G Compound Boring with Dwell

NOTES:

- All the default G-codes have been marked with the symbol " * ".

- A given line of a program may contain more than one G-code.

- If several G-codes from one group are used in the same line, only the G-code specified last will remain active.

- G-codes from group B are of "one shot" type (active only in the line in which they are specified). All other G-

codes are modal (active until another G-code of the same group is specified).

- If a G-code from group A is used in a canned cycle mode, the canned cycle will be canceled. Canned cycle G-

codes, however, have no effect on G-codes from group A.

G00 - Rapid Positioning

G0 moves to the specified position at the maximum motor rate. The coordinates may be either

absolute positions (G90) or incremental positions (G91). G0 is modal and remains in effect

until another positioning mode (G1, G2, G3 etc.) is commanded. G0 is the default-positioning

mode.

Loading...

Loading...