M-Series Operator’s Manual 4/9/15

G0X0Y0 ; Rapid tool to X0, Y0

G42D5 ; Turn cutter compensation on, with a diameter of D5

G0X0Y-1 ; Rapid tool to X0, Y-1

G1X.75Y-1 ; Linear cut to X0.75, Y-1.

X3.6 ; move X to 3.6

G40 ; Turn cutter compensation off.

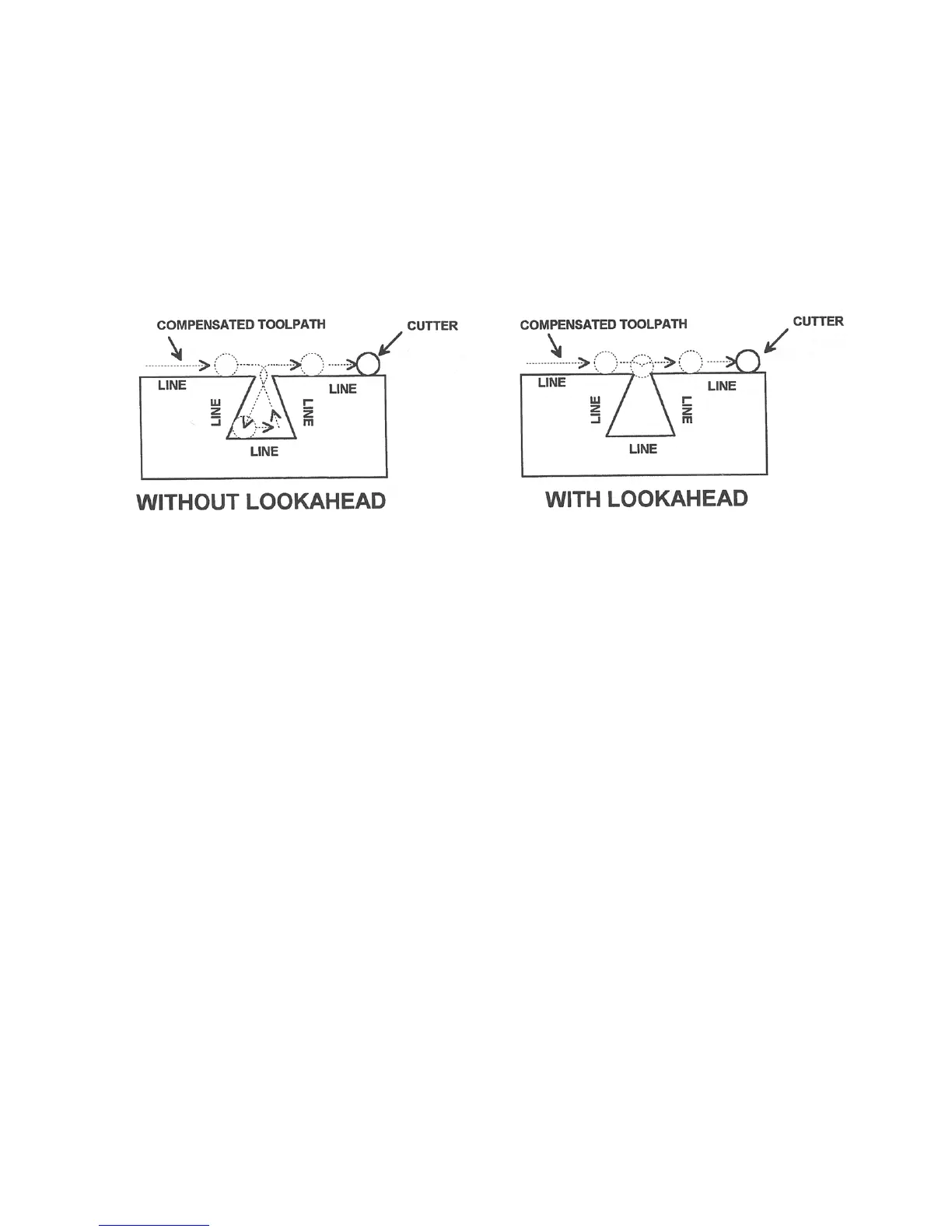

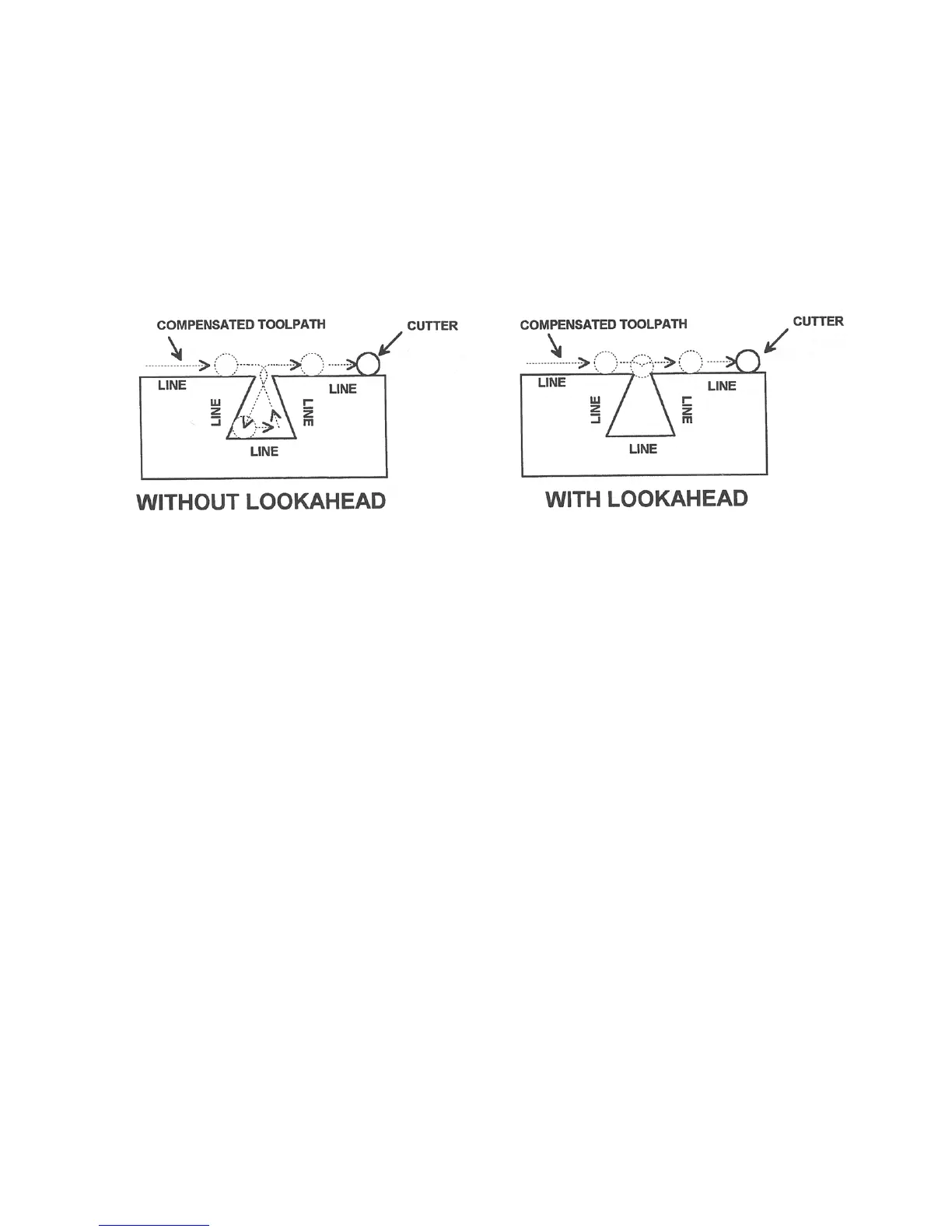

3. Lookahead. When the control machines any rapid traverse (G0), line (G1), or arc (G2, G3) with tool diameter

compensation enabled, the program will look up to N consecutive events ahead of the current event in order to

anticipate tool path clearance problems, where N is the number set in Parameter 99. Lookahead ensures that

compensated tool paths don't overlap in programmed part sections where there is not enough clearance for the tool.

The figure below shows a compensated tool path, and the actual tool path after Lookahead corrects the clearance

problem:

Refer to the “Machine Parameters” section in Chapter 14 for more information on Parameter 99.

G43, G44, G49 - Tool Length Compensation

G43 and G44 apply tool length compensation to a selected tool to allow the control to utilize multiple tools in a

single CNC program.

G43 applies positive compensation (from Z zero up). Work from part surface up.

G44 applies negative compensation (from Z zero down), used only when there is an absolute machine home. The

spindle face is considered a zero length tool and all offsets are from there down.

G49 cancels tool length compensation (also canceled by issuing G43 H00).

Example:

G43 H01 ; tells the machine to offset the amount that

; corresponds to H01 in the Offset Library

G43.3 - Tool Length Compensation (+) with Axis Tilt Compensation

G43.3 is a special compensation mode which applies positive tool length compensation on a selected tool, just like

G43, but also with additional X and Z compensations due to 5th axis tilt. This compensation mode is available only

on those machines configured with a triangular rotary 5th axis (see parameter 166 in Chapter 14). Note that this

compensation mode is the equivalent to G43 as long as the 5th axis is not tilted (i.e. local position is 0). G49

cancels this compensation mode.

G50, G51 - Scaling / Mirroring (Optional)

G50 and G51 scales program G-codes relative to a scaling center point defined as position (X, Y, Z).

A G51 applies scaling/mirror to all positions, lines, and arcs following this G-code, until a G50 is entered. Specify

scaling factors with a value I, J, K. The X, Y, and Z parameters are the coordinates of the scaling center. If the

scaling center is not specified, the default scaling center is the current cutter position as shown on the DRO. To

mirror, enter a negative value for the scaling factor.

Loading...

Loading...