M-Series Operator’s Manual 4/9/15

The “Summed Axis” is the axis that bears the position sum of itself with the “Axis to Sum with”. The DRO display

of the “Summed Axis” will show this summed position. The DRO will display both labels when displaying a summed

axis. Furthermore, G-codes that command movement on the “Summed Axis” will have their positions offset by the

position of the “Axis to Sum with”.

NOTICE

It is highly recommended that summing be done with Local Coordinates (using the ‘-’

sign in the parameter value). Summing with Machine Coordinates can cause the effective

software travel limits to move, thus resulting in physical overtravel or severely

handicapping the amount of available travel, due to the fact that software travel limits are

defined in terms of Machine Coordinates. Summing with Local Coordinates avoids this

problem.

Here are some examples:

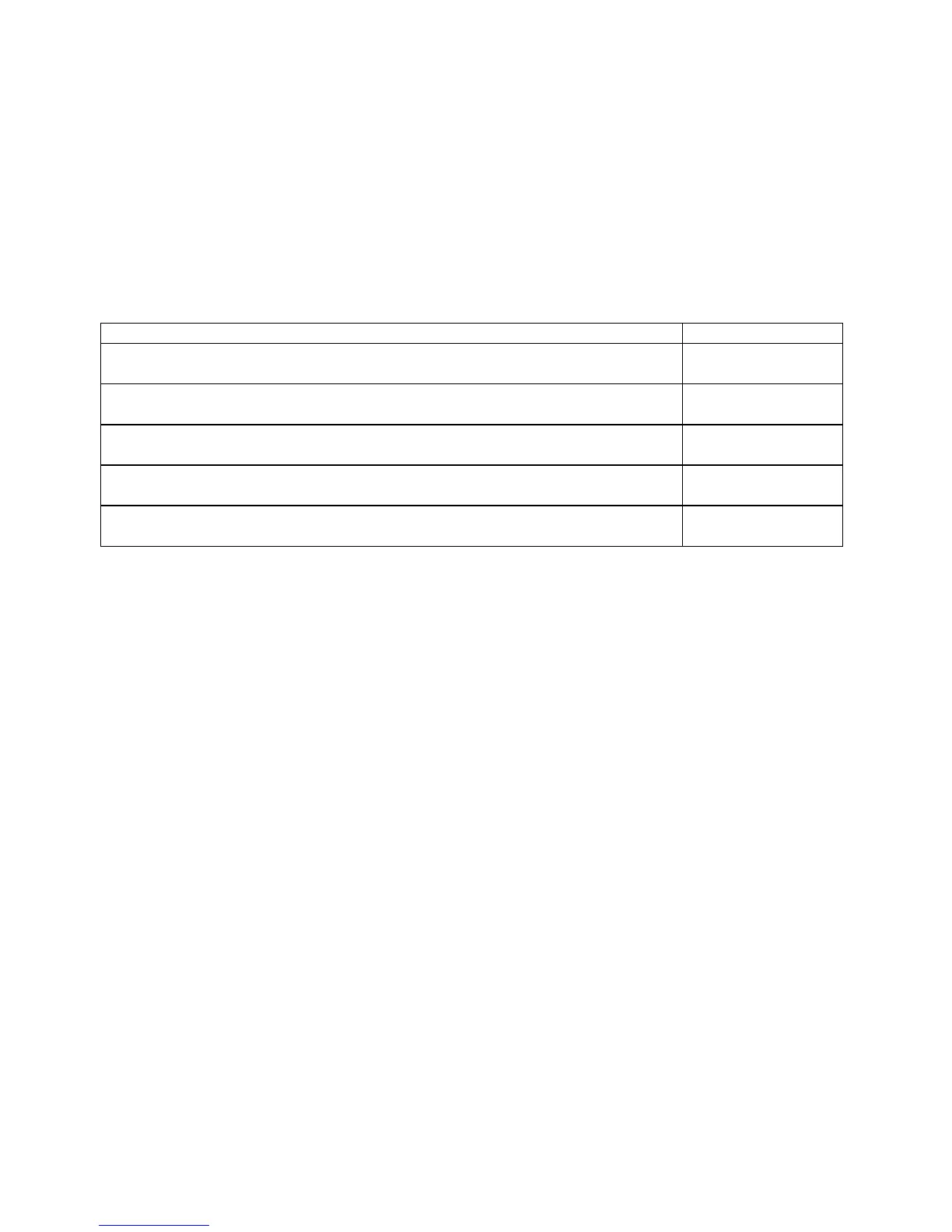

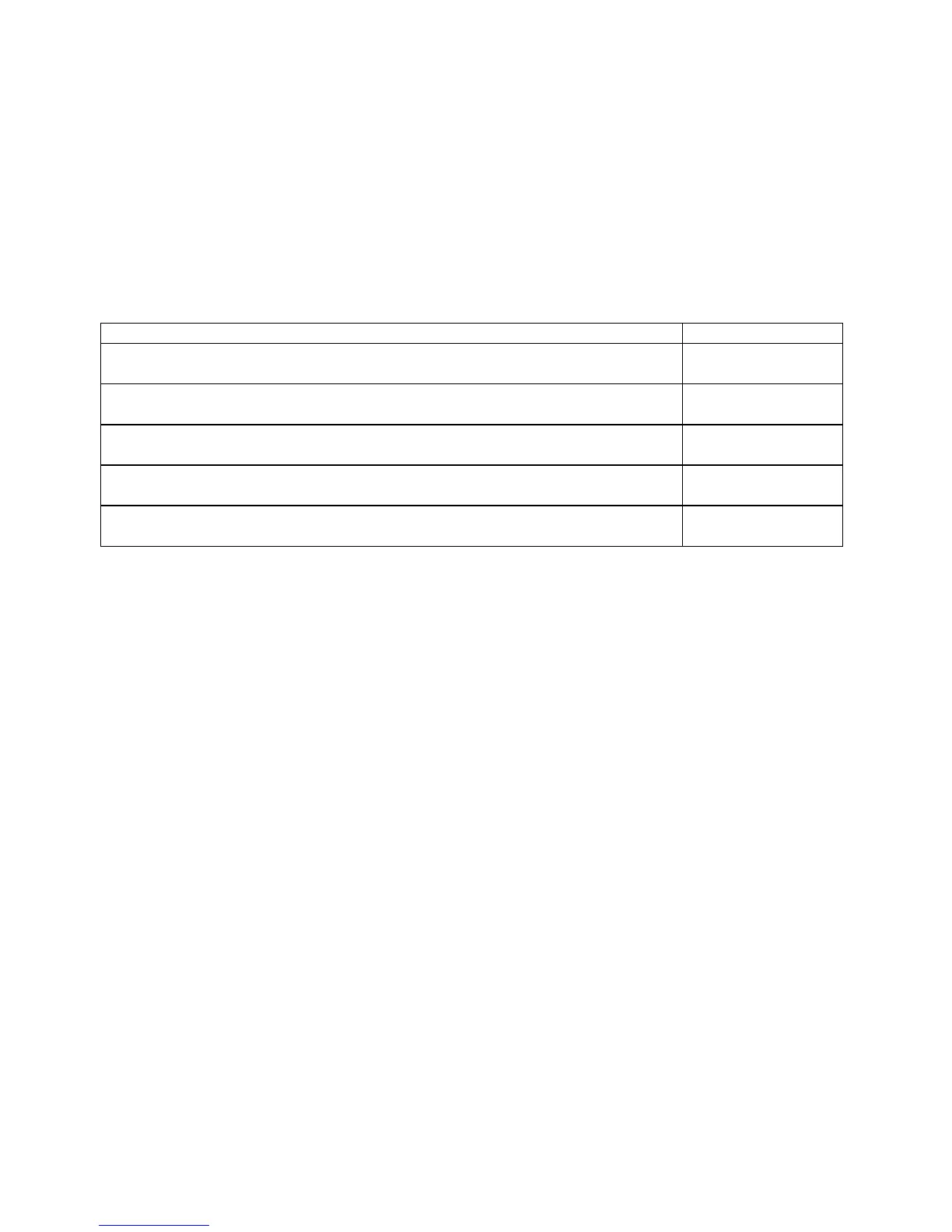

Desired Display Parameter

Axis 3 DRO will display the result of axis 3 and 4 machine coordinate positions

summed together.

400

Axis 4 DRO will display the result of axis 4 and 3 local coordinate positions

summed together. Machine coordinate positions are not affected.

-3000

Axis 3 DRO will display the result of axis 3 and 4 local coordinate positions

summed together. Axis 4 DRO display will be disabled.

-6400

Axis 4 DRO will display the result of axis 4 and 3 local coordinate positions

summed together. Axis 3 DRO display will be disabled.

-3600

Axis 3 DRO will display the result of axis 3 and 4 local coordinate positions

summed together. Axis 4 will be displayed only if it moves.

-7400

Parameter 76 – Manual Input Unrestricted Distance

This parameter is intended to be used with Z-axis summing. It defines the maximum distance from the summed axis

start of travel in which manual movements can occur without causing a fault. Use a negative value to specify a

distance from the minus travel limit, a positive value for a distance from the plus travel limit.

When used with manual drilling, for example, setting this parameter will allow the operator to keep a hand on the quill

at all times and even begin pulling on the quill in anticipation of a programmed stop.

Setting this value to zero will cause a fault if there is any manual movement.

To completely disable manual movement restrictions, set this parameter to a value exceeding the total travel of the

summed axis.

Minimum = -99999.9999, maximum = 9999.9999, default = 0, typical = +/- 1.0 inch or +/- 20.0 mm

Parameter 77 – Manual Input Movement Tolerance

This parameter specifies the manual movement tolerance while a job is running. It is intended for use with a quill

locking mechanism. It allows the lock to distort and/or slip a small amount when under stress. If the quill moves more

than the given tolerance, the job will stop with a fault. A typical setting for Parameter 77 is 0.005 inches.

Parameter 78 – Spindle Speed Display and Operations

Bit 0 (value = 1) specifies how the spindle speed is determined and displayed in the CNC software status window.

When turned on (value = 1), the spindle speed is determined by reading the encoder feedback from the axis specified

according to parameter 35. Which has the number of encoder counts/revolution specified in parameter 34. When

turned off (value = 0), the displayed speed is not measured; the speed is calculated based upon the programmed speed,

spindle override adjustment, and gear range.

Bit 1 (value = 2) allows the control to prorate the programmed feedrate to be proportional to the spindle speed if the

spindle speed ever slows down below the spindle speed threshold percent as set by parameter 149.

Loading...

Loading...