M-Series Operator’s Manual 4/9/15

Bit 2 (value = 4) will turn on the “Spindle up-to-speed” function. The active modal spindle speed S at the point where

the most recent M3 or M4 is invoked sets the target spindle speed for this function. This function is invoked on the

first feed-per-minute move (such as G1/G2/G3) following the aforementioned M3 or M4. If the actual measured

spindle speed at this moment is below the spindle speed threshold percent (parameter 149) of target spindle speed, this

function will pause the job at this point until the spindle speed gets up to at least this spindle speed threshold percent

level.

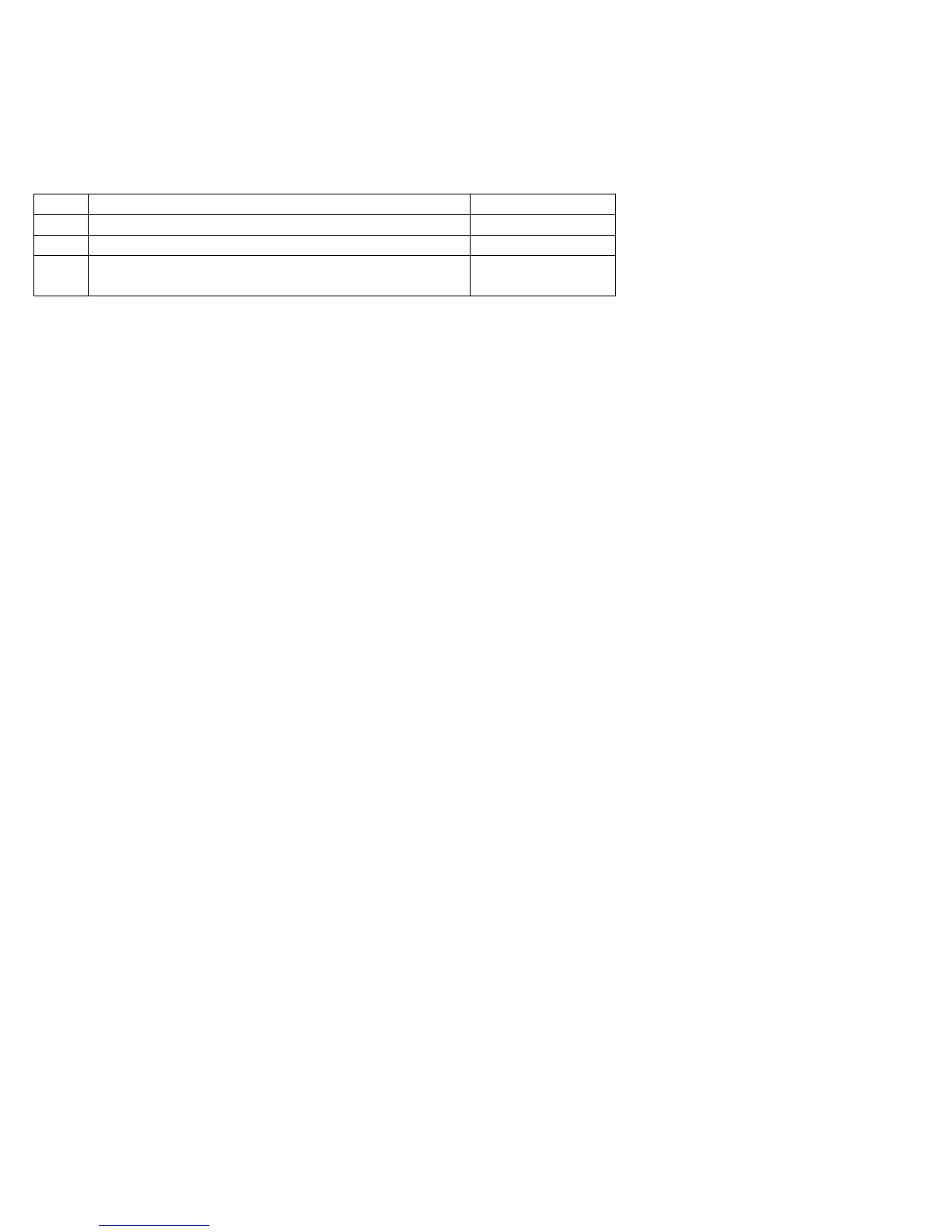

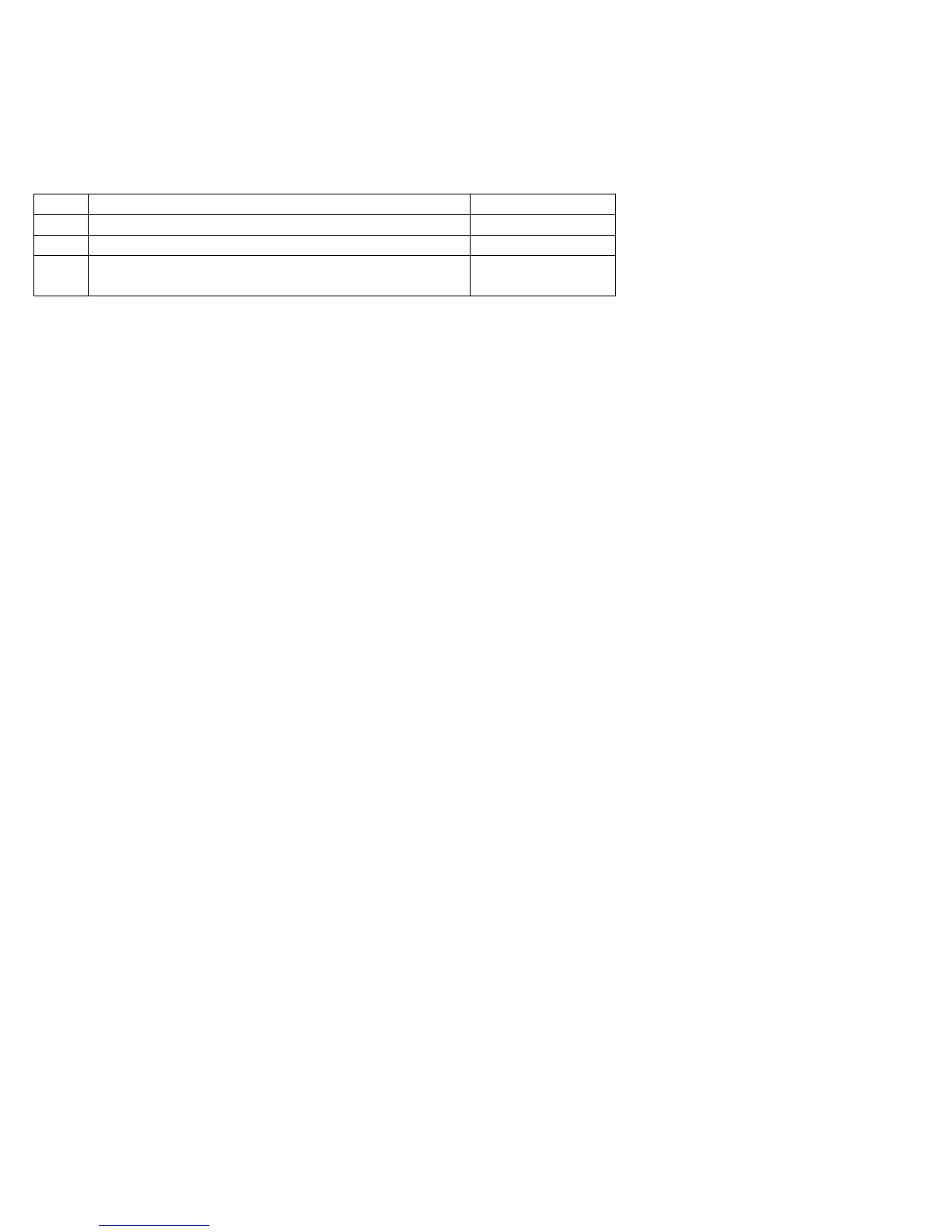

Bit Function Value

0 Display actual spindle speed Yes = 1, No = 0

1 Slave feedrate to spindle speed Yes = 2, No = 0

2 Wait for spindle to get up to speed on feed-per-

minute moves

Yes = 4, No = 0

Parameter 80 – Voltage Brake Message Frequency

This parameter specifies the number of times the “450 Voltage brake applied” message has to occur before we show it

in the message window and message log. A value of 0 or 1 will display the message for every instance that it occurs.

Parameter 81 – Air Drill M-function (Canned Cycle Parameter)

P81 (when not equal to –1.0) specifies the M-function to be called in place of Z-axis movement during a G81 drilling

cycle.

Parameter 82 – Spindle Drift Adjustment (Rigid Tapping Parameter)

This value is the number of degrees that the spindle will take to coast to a stop, when the spindle is turned off at the

minimum spindle speed specified by parameter 68.

Parameter 83 – Deep Hole clearance amount (Canned Cycle Parameter)

Parameter 83 specifies the clearance amount used during a G83 deep hole drilling cycle.

Parameter 84 – M function executed at return to initial point of tapping cycle (Canned Cycle Parameter)

This specifies the number of the M-function that is executed after the G84 tapping cycle is done (returned to the initial

point). This also specifies the number of the M-function that is executed at the bottom of the G74 countertapping cycle

(to reverse the spindle in preparation for pulling out of the countertap hole).

Parameter 85 – “Door Open” Interlock PLC bit

This parameter provides a way for a system integrator to implement a safety interlock that limits rate of movement

when the doors are open. This parameter specifies the PLC bit number and PLC bit polarity that indicates the "door

open” condition. If the specified PLC bit is in the specified “door open” condition, then all normal movement

commands (G0, G1, G2, G3) will be limited to the slow jog rate (as specified in the Jog Parameters menu in Machine

Configuration). Polarity of the “door open” condition is specified thuswise: a positive number indicates that the “door

open” condition occurs when the specified PLC bit is On, and a negative number indicates that the “door open”

condition occurs when the specified PLC bit is Off. If this parameter is set to 0 (the default value), then this feature is

disabled, and no checking for a “door open” condition is done. Note that this feature has no effect for movement

commands handled by Smoothing (P220=1). Also note that PLC program interaction is needed for this feature to work.

Parameter 86 – Rapid/Linear vector rate limit

This parameter controls the feature that imposes a limit on the number of rapid and/or linear moves per second to the

value specified in this parameter. If the value of this parameter is more than 0, Rapid and/or Linear moves will be

combined to prevent the aforementioned limit from being exceeded. This parameter is used for testing purposes and

should be set to 0 to disable this feature. Note that this feature has no effect for movement commands handled by

Smoothing (P220=1).

Loading...

Loading...