M-Series Operator’s Manual 4/9/15

5. Feature width W (P226)

W and Min_Angle work together to determine which angles will be "sharp" (not be smoothed). For example a Gcode

file may contain small spikes, double backs or zig zags of less 1mm that may be causing unwanted

slowdowns in an otherwise high speed stretch of toolpath. Given a STEP (P222) = .25mm , setting W (P226)= 4

(4*.25=1mm) should reduce or eliminate decelerations across the problem toolpath. W does not itself smooth

the offending data, that's the job of Smoothing (controlled by NBpts and STEP), but W does allow you to

minimize slowdowns caused by small features, which is very helpful for running smooth thru jagged CAD/CAM

generated G code.

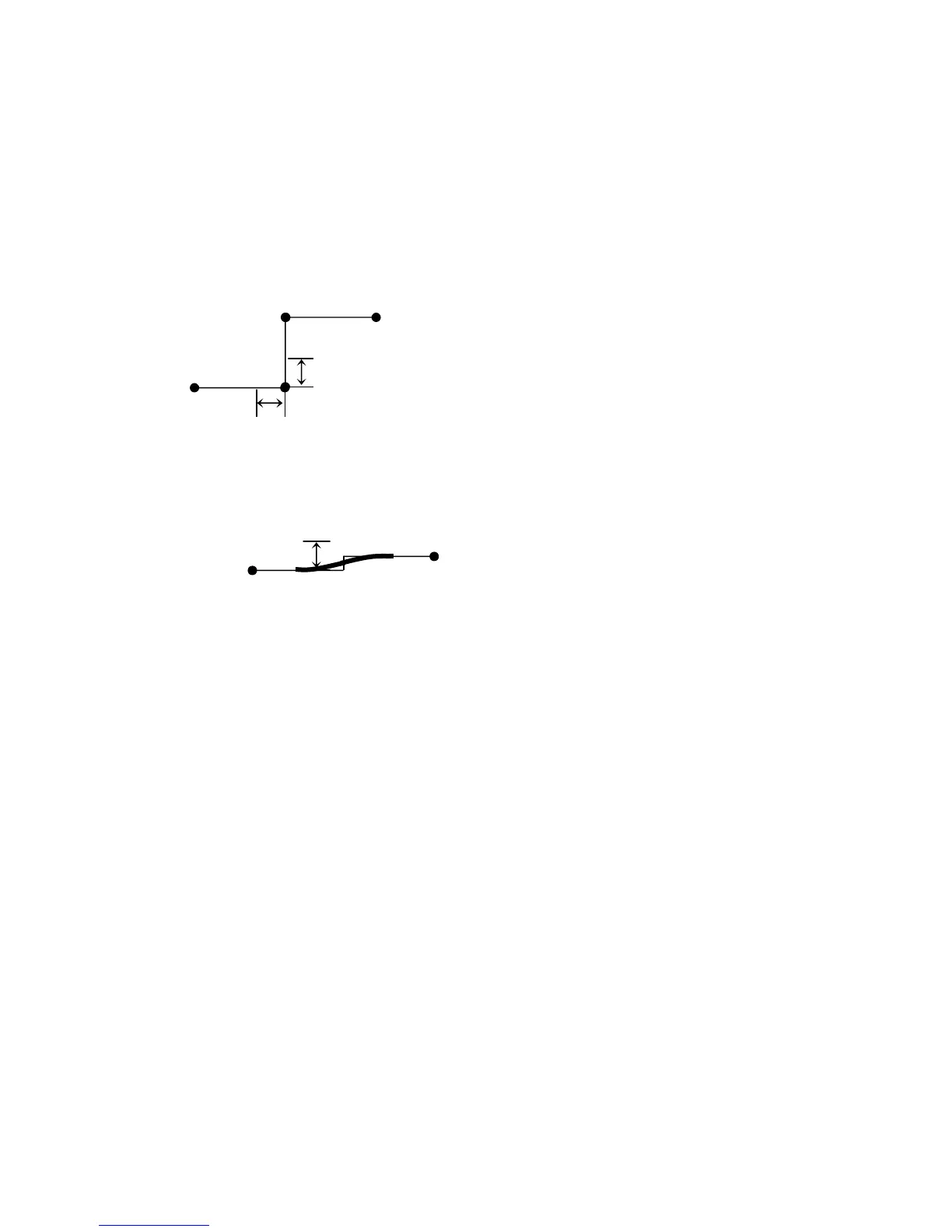

Fig 6. W determines whether or not a feature is significant

Feature is larger

than W x Step

This feature is significant.

Therefore, if the feature’s angles are less than

Min_Angle (P227) they will be shapened.

Otherwise, smoothing will be applied.

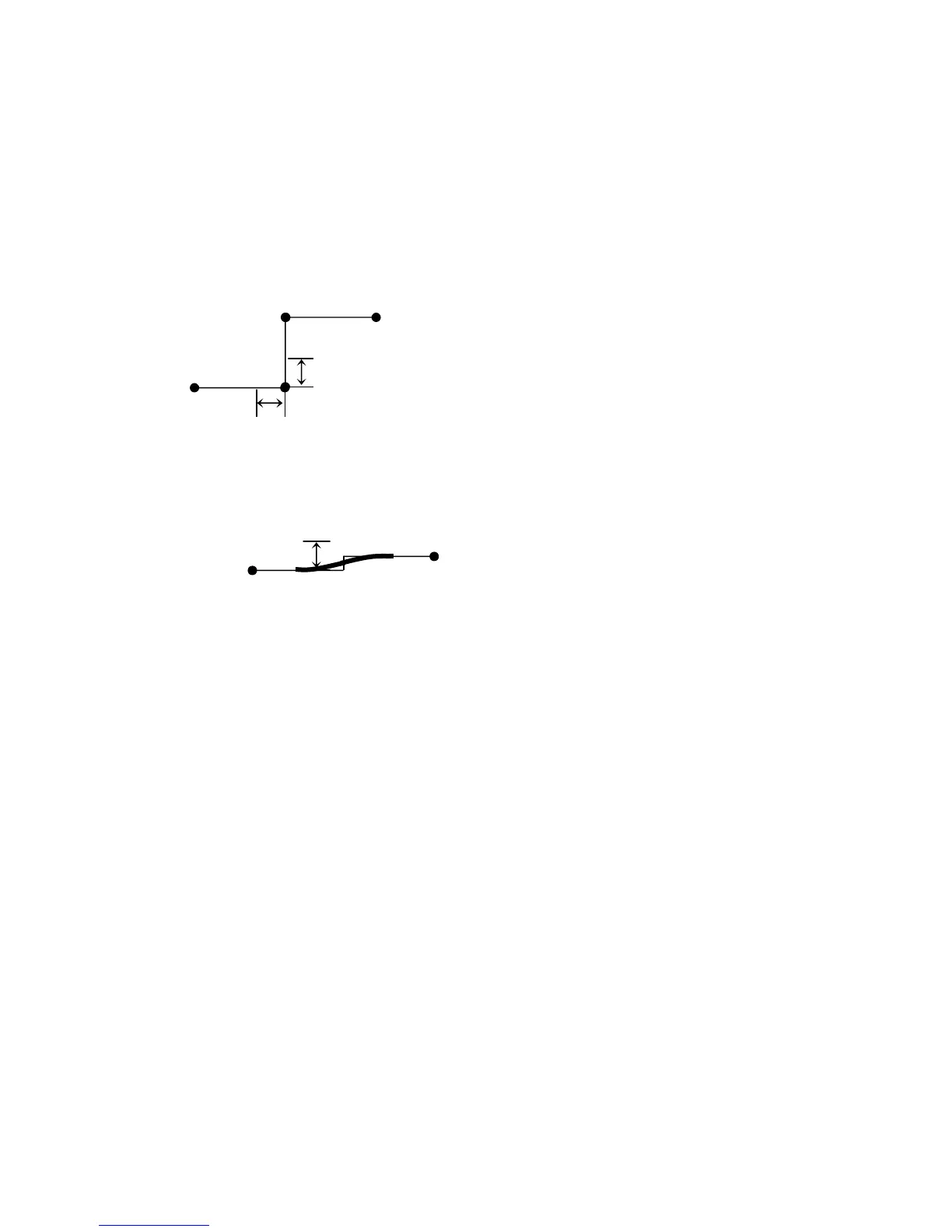

Feature is smaller

than W x Step

Because this feature is considered insignificant,

smoothing will be applied over it.

Loading...

Loading...