161

Danger of injury from electric shock

Cleaning/maintenance works at a device which is not disconnected from

the electrical power supply may lead to severe injury or even death.

• Maintenance work on electrical components may only be carried out

by specialist electricians.

• Before starting cleaning/maintenance, disconnect the device.

• Measure the voltage in the intermediate circuit.

• Check that the capacitors are discharged. After switching-off the main

switch, wait at least 5 minutes.

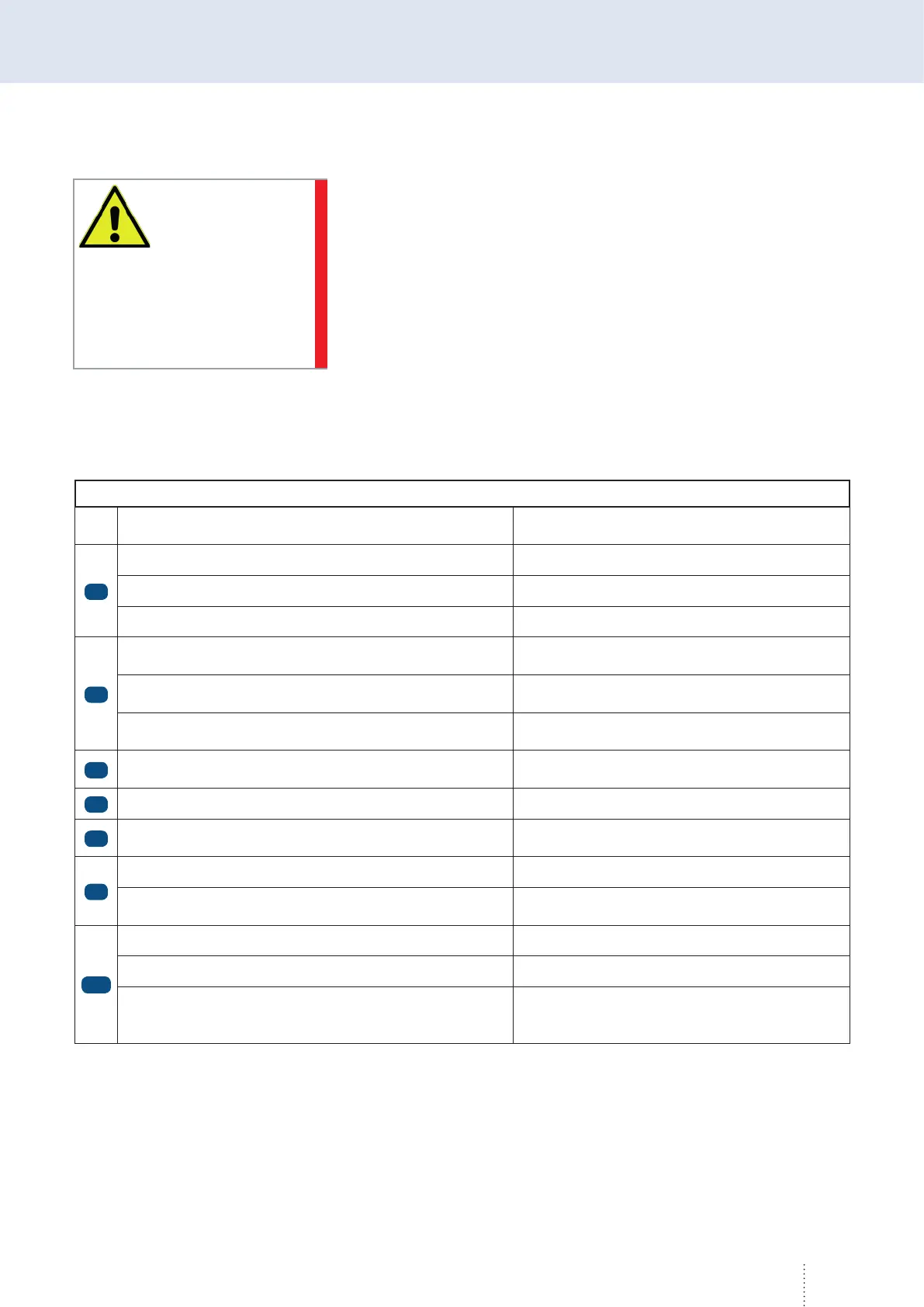

1.1 Regular testing

DANGER!

Control Remedy

Each time before starting work

Damages and professional connection of all mains connections

and lines of movable welding power sources.

Contact a qualified electrician.

1

Damage to the gas bottle safety element. Secure the gas bottle properly from falling.

The correct attachment and tightness of the gas hoses. Fix / change the gas hoses / connections.

The correct gas flow quantity. Re-adjust the gas flow quantity.

4

Dirt at nozzle base, gas distributor, current tip and gas nozzle. Clean current tip and gas nozzle from dirt.

Damages and intact insulation of the torch neck of the manual

welding torch.

Contact a qualified electrician.

The correct attachment of the manual welding torch (central

connection).

Re-tighten the fixtures of the manual welding torch.

6

The correct attachment and the external damages of the

connection cable assembly.

Contact a qualified electrician.

7

External damage to the mains supply cables. Contact a qualified electrician.

8

The quantity of the coolant.

Refill coolant.

000010131 = Coolant 5l

9

The intact insulation of the welding power jacks. Contact a qualified electrician.

The correct attachment, damage to the earth jack, earth cable

and earth clamp.

Re-tighten the fixtures of the earth cable.

Contact a qualified electrician.

11

The brake at the wire coil. Re-adjust the brake.

The correct position and attachment of the wire coil. Fix the wire coil.

The correct attachment of the wire feeding components (wire

drive rollers, wire feed pipe, wire inlet nipple, liner).

Re-tighten the fixtures of the wire feeding

components.

Clean the wire feeding elements.

Loading...

Loading...