65

Always use rotary knob 1 to set the wire speed.

Use rotary knob 2 to set the most important electrical parameters depend-

ing on the process. Depending on the selected process, the parameters

voltage, frequency or the arc length are selected.

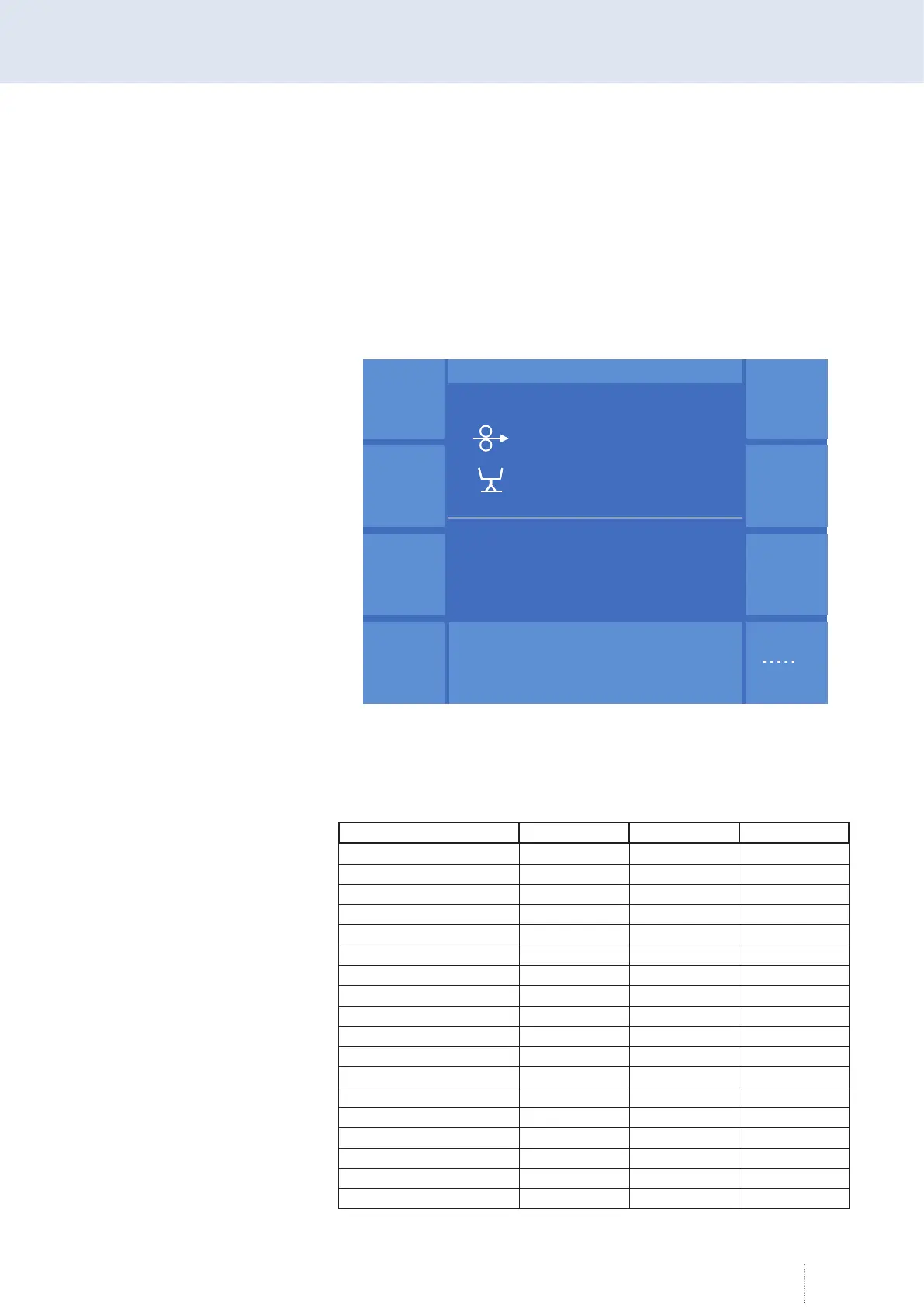

Use rotary knob 3 to select further welding relevant parameters depending

on the process. By pressing rotary knob 3 you reach the next parameter, see

Figure 22.

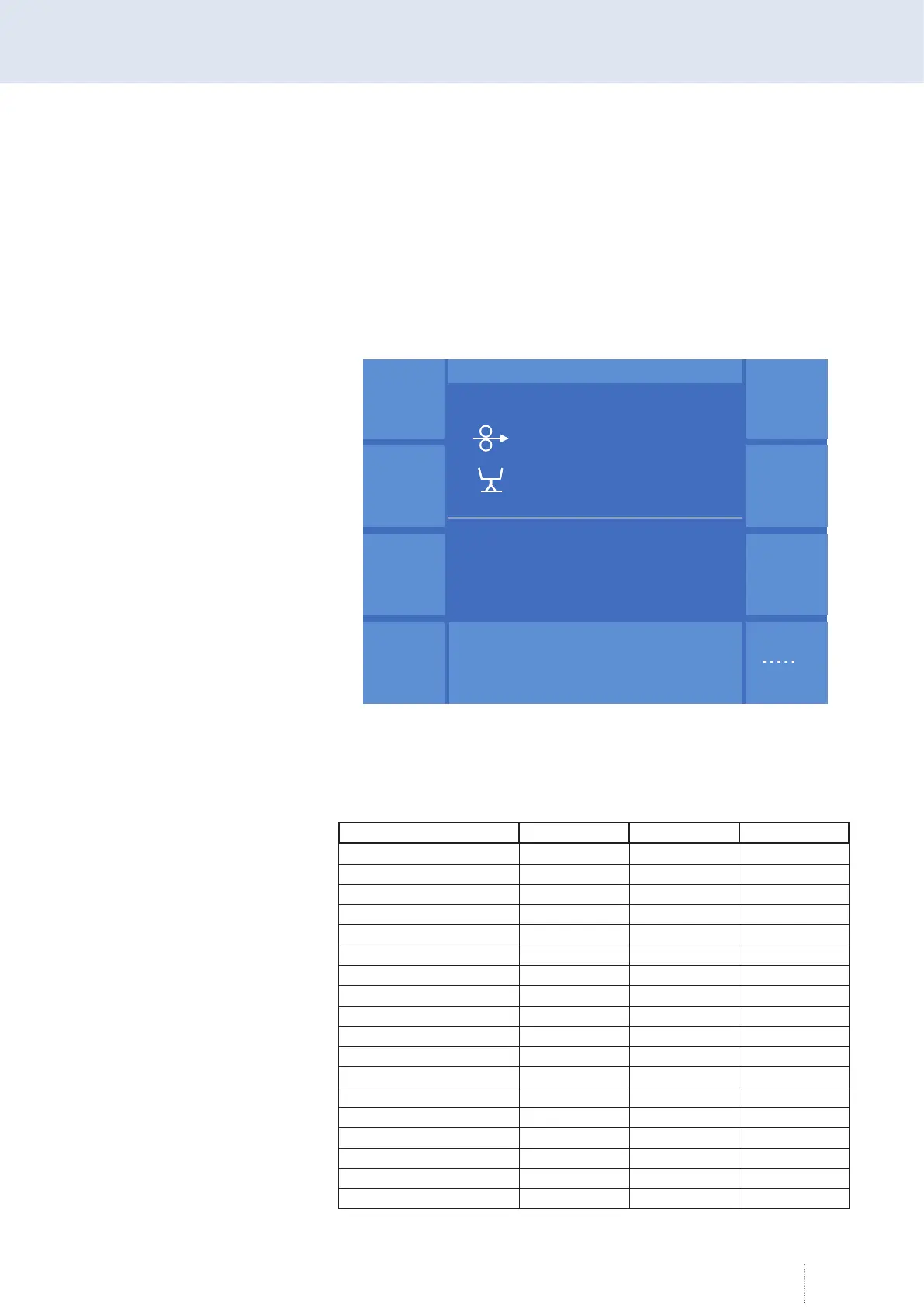

7.7.2 Secondary parameters in the "Expert Mode"

Depending on the process, the following secondary parameters are avail-

able:

Parameters MAG Normal Pulse S-Pulse

Time (duration) x x x

Upslope x x x

Wire speed

Downslope x x x

Gas pre-flow x x x

Gas post-flow x x x

Inching-in x x x

Ignition mode x x x

Voltage x

Choke x

Burnback x x x

Inclination x

Arc length x

Pulse frequency x x

Base current x x

Pulse time x x

Pulse current x

Pulse voltage x

Synergie

Betr.

Verfahren

Funktion

M A I N

Progr.

Messwerte

S-Puls 4 -Takt

12.6

m / min

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

C - Start

Pulszeit 2.0 ms

Pulsspannung 38.5 V

Grundstrom 60 A

265

Hz

Synergie

Betr.

Verfahren

Funktion

M A I N

Progr.

Messwerte

S-Puls 4 -Takt

12.6

m / min

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

C - Start

Pulszeit 2.0 ms

Pulsspannung 38.5 V

Grundstrom 60 A

265

Hz

Figure 22. "MAIN" "Expert Mode" function active

Loading...

Loading...