55

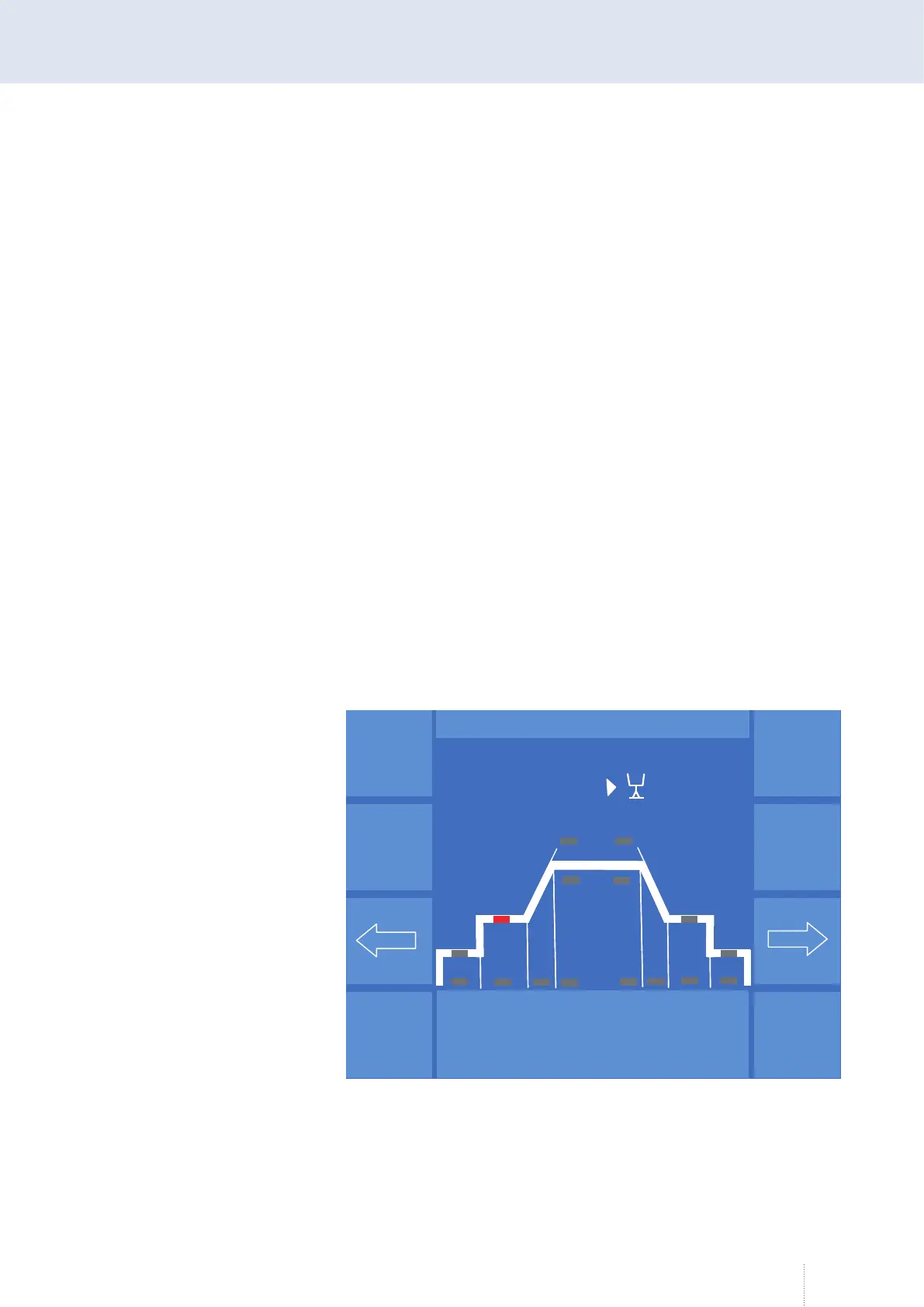

7. MAIN - Progr. (Programming)

The welding power source always uses the existing synergic characteristic

curves. The values for all secondary parameters, including "CleanStart", are

already preset in the synergy characteristic curves.

Activate the "Programming" function to enter the programming mode. In

this menu the default values can be adjusted.

The correction is only an offset which is added to the characteristic curves.

The original characteristic curve is not changed. It can always be reset to

the original state (display "- 0 -").

In programming mode, the following display concept applies:

Yellow = time

Green = m/min, step size

Red = power

In the programming mode, you can access the next or previous parameter

by shortly tapping on the arrow buttons. A graphic display is integrated for

better orientation.

Above the graphic display the current parameter, the correction factor and

the absolute numerical value with the corresponding physical dimensions

are displayed. Depending on the selected parameter, the display may differ

from the example shown in Figure 11.

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

Startleistung

Dyn.

6.0 m/min

- 0 -

6

2

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

Startleistung

Dyn.

6.0 m/min

- 0 -

6

2

Figure 11. Programming menu

Loading...

Loading...