56

MAIN - Progr. (Programming)

The correction value is entered by means of the rotary knob 3. The changed

parameters are saved simultaneously and do not have to be saved addi-

tionally.

During the Job mode, the job has to be saved again! If you did not save the

correction values in a job, the settings of the last selected characteristic

curve are lost!

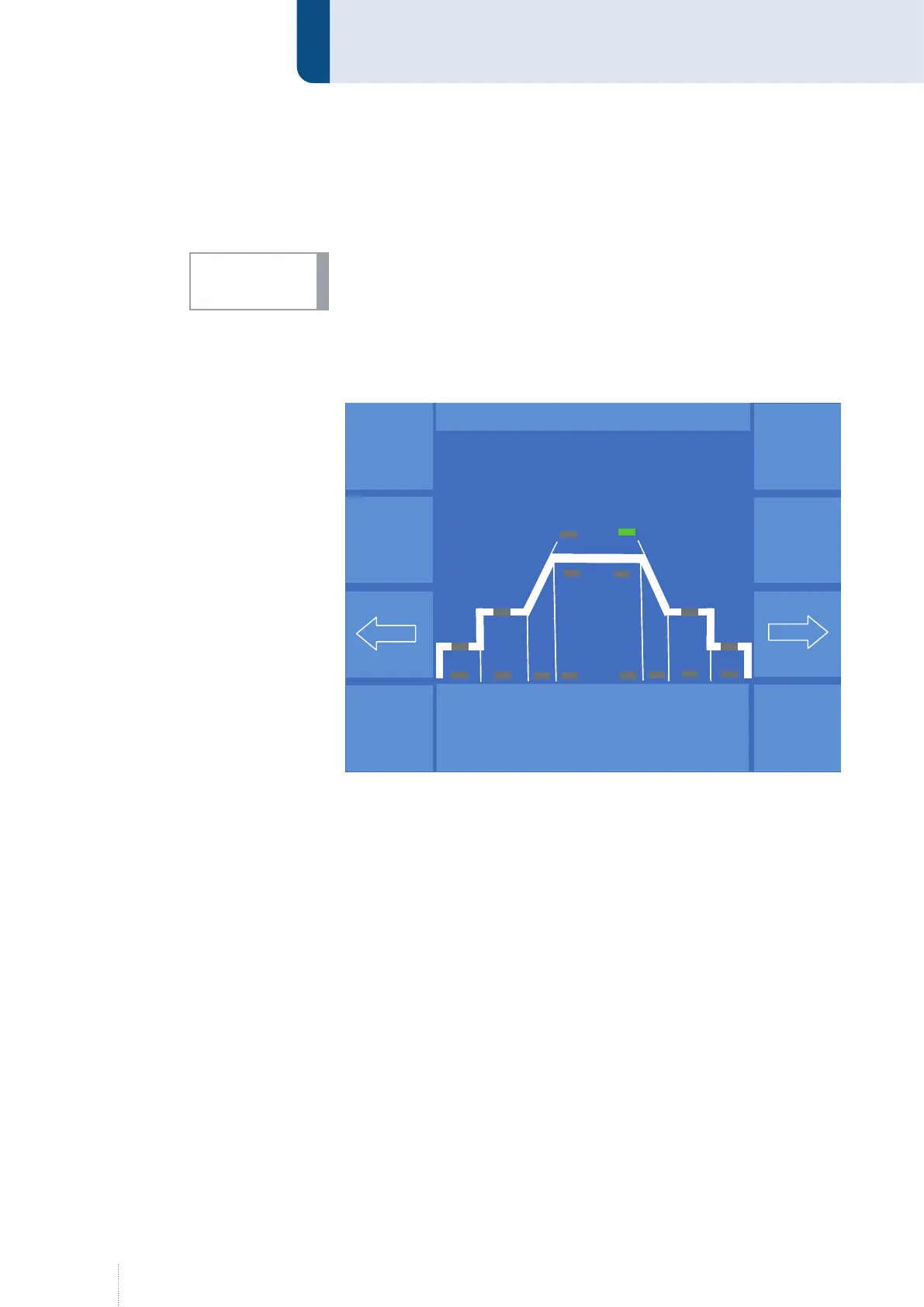

The numerical values are dimension-free correction values and no absolute

numerical values. The absolute numerical value with the corresponding

physical size is shown in a separate line, see example Figure 12.

When times are corrected (yellow LED), an "OFF" is displayed after "-99". The

function (e.g. Start program) is switched off if "OFF" is displayed.

All correction values are reset to "- 0 -" as soon as another gas/material

combination or another wire diameter is selected.

INFO!

Figure 12. Menu programming correction -0-

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

DuoPuls - Frequenz

1.5 Hz

- 0 -

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

Puls 4 -Takt

V

0

A

1.2 mm Fe

82% Argon 18% Co

2

0.0

P R O G R A M M I E R E N

DuoPuls - Frequenz

1.5 Hz

- 0 -

Loading...

Loading...