75

In this menu, the basic settings for the use of the welding power source are

made.

Start/End program in 2-cycle mode

For welding applications it is often not required to use start and end crater

programs (e.g. frequent spot welding).

Therefore, you have the option to switch off this function. You can choose

between the settings "On" and "Off". This modification becomes only effec-

tive when the characteristic curve is called up again.

External control

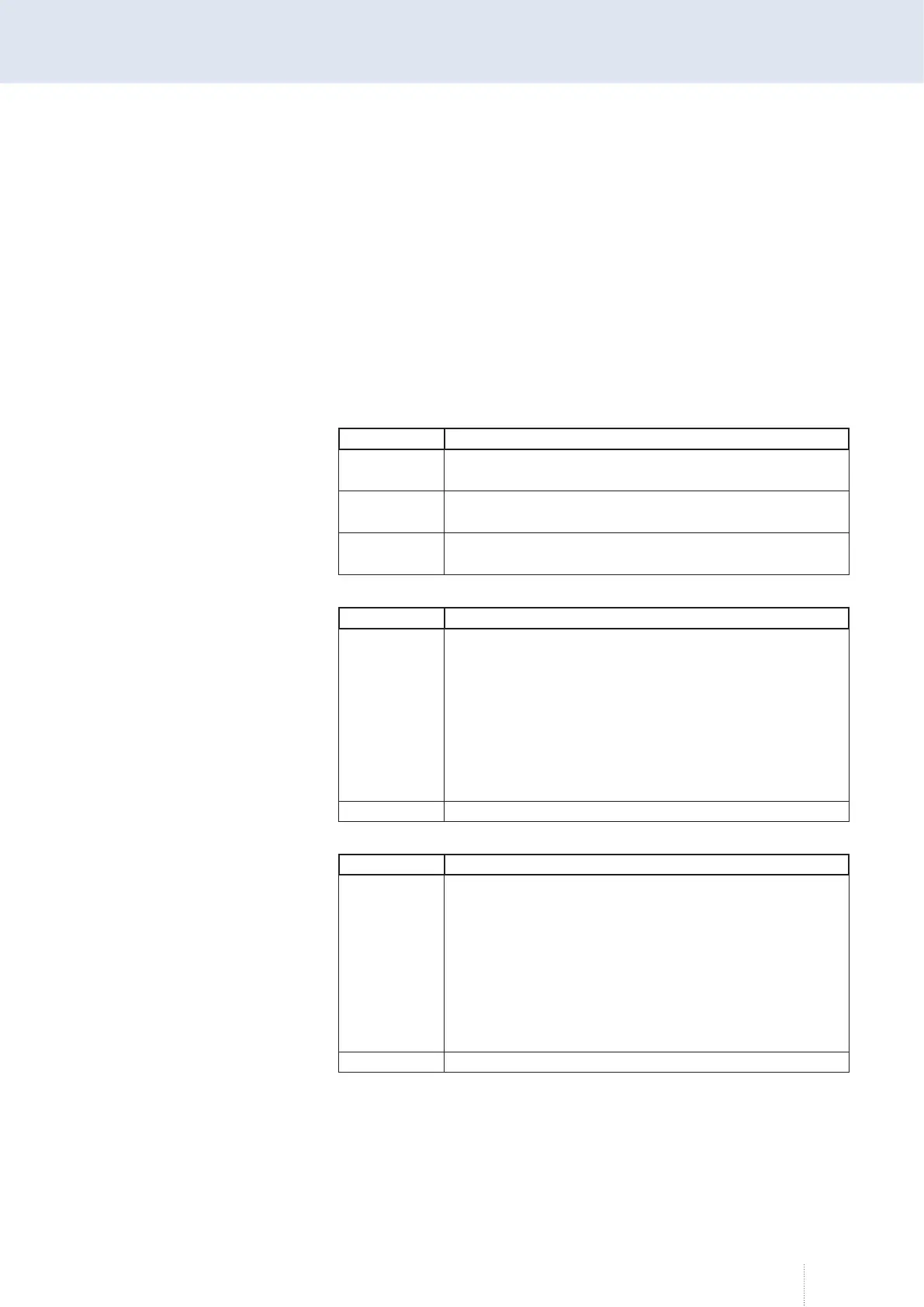

• Number of control voltages

Name Function

"0"

• If the robot shall only set the job number, but no other

parameters.

"2"

• If the robot shall set the two parameters “Arc length”

and “Power”.

"3"

• If the robot shall set the three parameters “Arc length”,

“Power” and “Dynamics”.

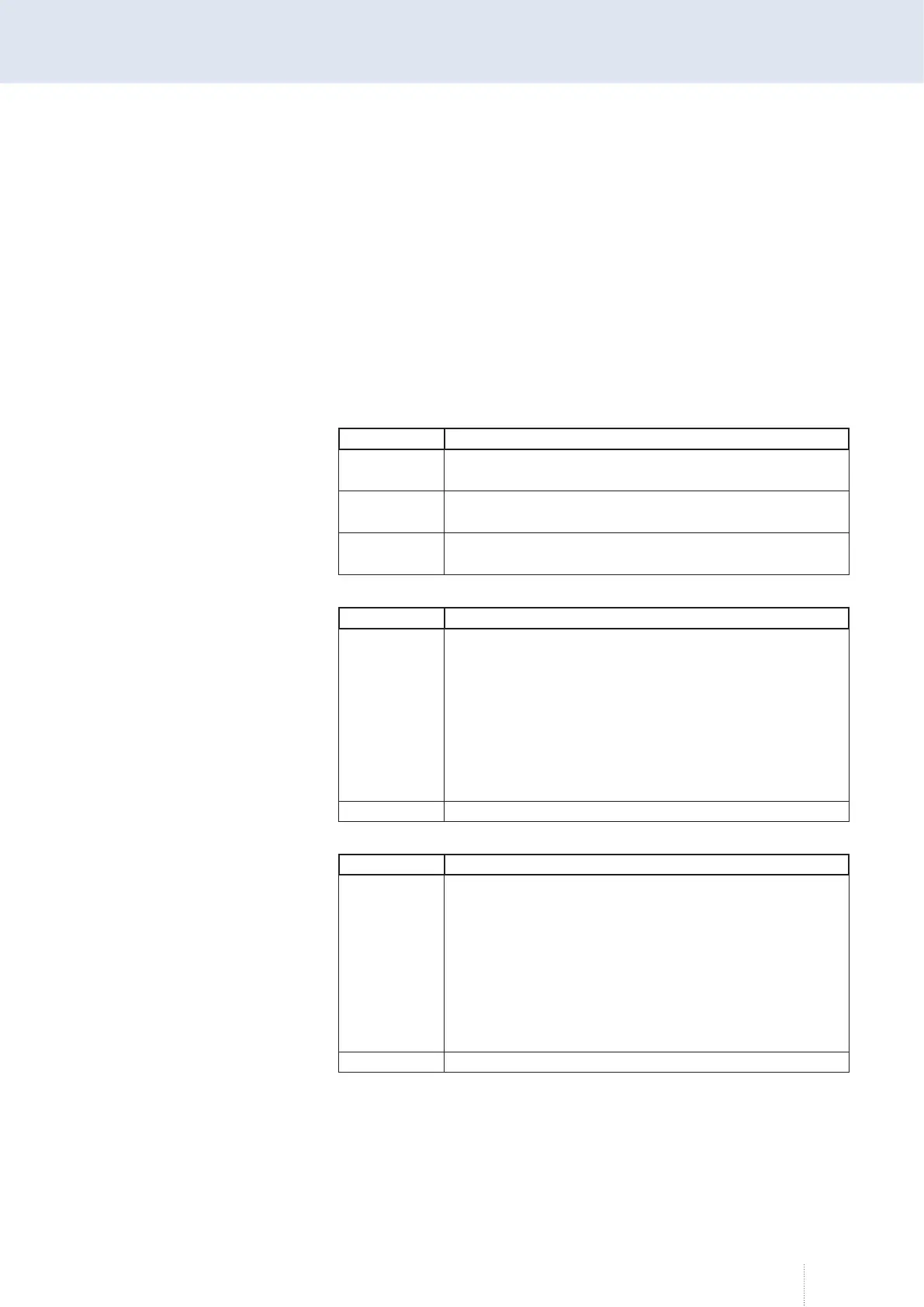

• External process selection

Name Function

"Off"

• If two different processes are executed at the same

time with a Tandem torch.

• If variants of synergy characteristic curves are used.

• If a correction value for Upslope or Downslope was set

and the robot changes the process during operation.

The correction value is also taken over for the following

process! If you do not want this behaviour, we recom-

mend to change the process via a job change.

"On" • If the robot shall pre-set the welding process.

• Qirox parameters

Name Function

"Off"

• If the welding power source shall pre-set the welding

parameters.

Necessary if no other welding parameters shall be trans-

ferred from the robot to the welding power source during

job operation.

The values for "Number of control voltages" and "External

process selection" have an indirect influence on these

parameters and can be set separately.

"On" • If the robot shall pre-set the welding parameters.

Loading...

Loading...