FC 300 Design Guide

How to Program

Function:

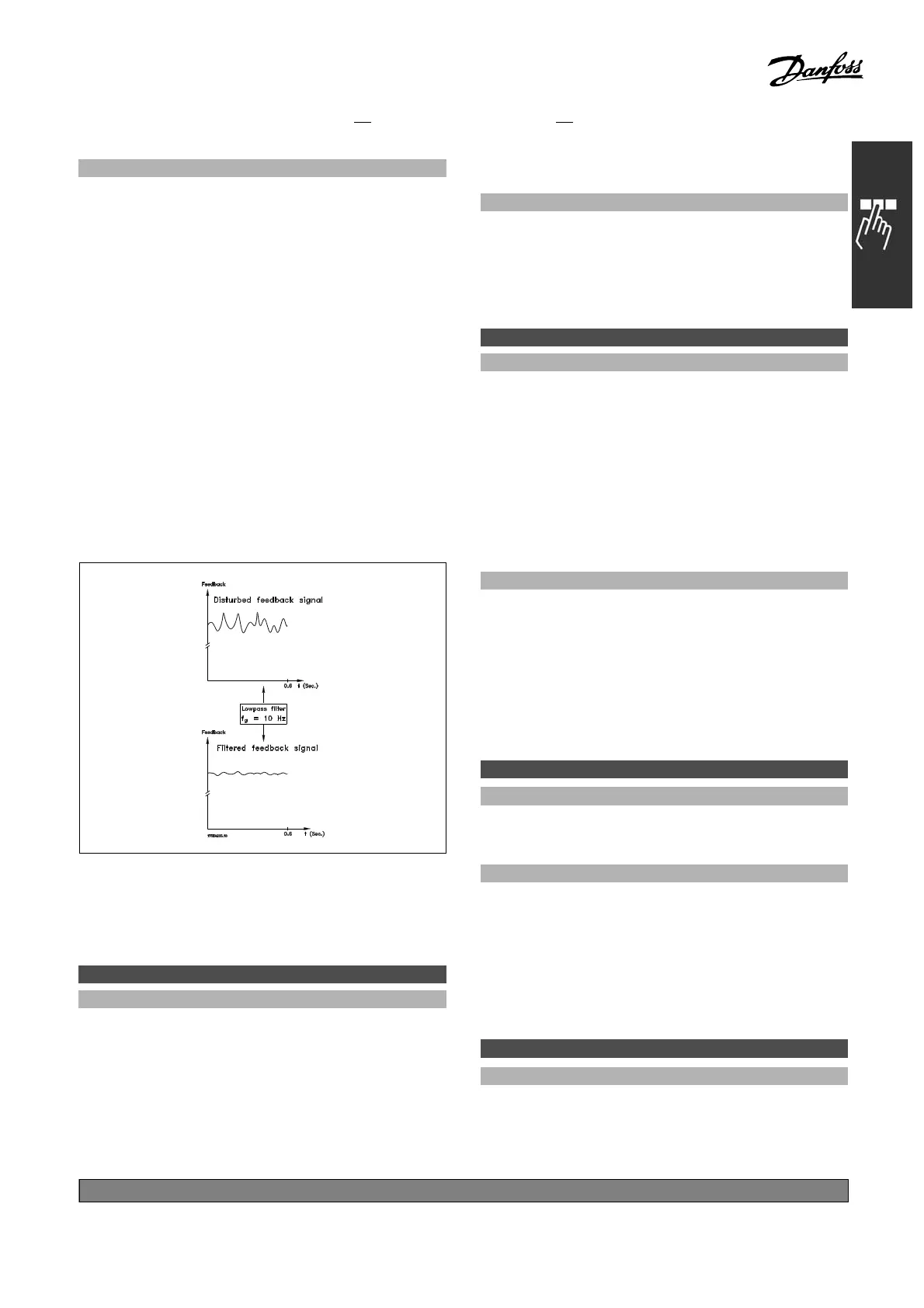

Set a time constant for the speed control low-pa ss

filter. The low-pass filter improves steady-state

performance and dam pens oscillations on the

feedback signal. Thi s is an advantage if there

is a great amount on noise in the system, see

illustration below. For example, if a time constant

(τ) of 100 ms is programmed, the cut-off frequency

for the low-pass filter w ill be 1/0.1= 10 RAD /sec.,

corresponding to (10/2 x p) = 1.6 Hz. The P ID

regulator only regulates a feedback signal that

varies by a frequency of less than 1.6 Hz. If the

feedback signal varies by a higher frequency than

1.6 Hz, the PID regulator does not react.

Note that severe filtering can be detrimental

to dynam ic performance.

This parameter is used with par. 1-00 Speed

closed loop [1] and Torq ue [2] control.

" 7-2* Process Ctrl. Feedb.

Select the f ee dback sources for the Process PID

Control, and how this feedba ck should b e handled.

7-20 Process CL Fee dback 1 Resource

Option:

*

No function [0]

Analog input 53 [1]

Analog input 54 [2]

Frequency input 29 [3]

Frequency input 33 [4]

Bus feedback 1 [5]

Bus feedback 2 [6]

Analog input X30/11 [7]

Analog input X30/12 [8]

Function:

The effective feedback signal is made up of the

sum of up to two different input signals.

Select which frequency converter input should be

treated as the source of the first of these signals.

The second input signal is defined in par. 7-22.

7-22 Process CL F ee d b ack 2 Resource

Option:

*

No function [0]

Analog input 53 [1]

Analog input 54 [2]

Frequency input 29 [3]

Frequency input 33 [4]

Bus feedback 1 [5]

Bus feedback 2 [6]

Analog input X30/11 [7]

Analog input X30/12 [8]

Function:

The effective feedback signal is made up of the

sum of up to two different input signals. Select

which frequency converter input should be treated

asthesourceofthesecondofthesesignals. The

first input signal is defined in par. 7-21.

" 7-3* Process PID Ctrl.

Parameters for configuring the P roce ss PID control.

7-30 Process PID No rmal/Inverse Control

Option:

*

Normal [0]

Inverse [1]

Function:

Select Normal [0] to se t the process control

to increase the output frequency.

Select Inverse [1] to set the process con

trol

to reduce the output frequency. Normal and

inverse control are implemented by introducing

a difference between the r efere n c

esignal

and the feedback signal.

7-31 Process PID Anti Windup

Option:

*

Off [0]

On [1]

*

default setting ()display text []value for use in communication via serial communication port

209

MG.33.B

6.22 - V LT is a registered Danfoss trademark

Loading...

Loading...