FC 300 Design Guide

How to Install

" Electrical Installation

NOTE

Cables General

Always comply with national and local regulations on cable cross-sections.

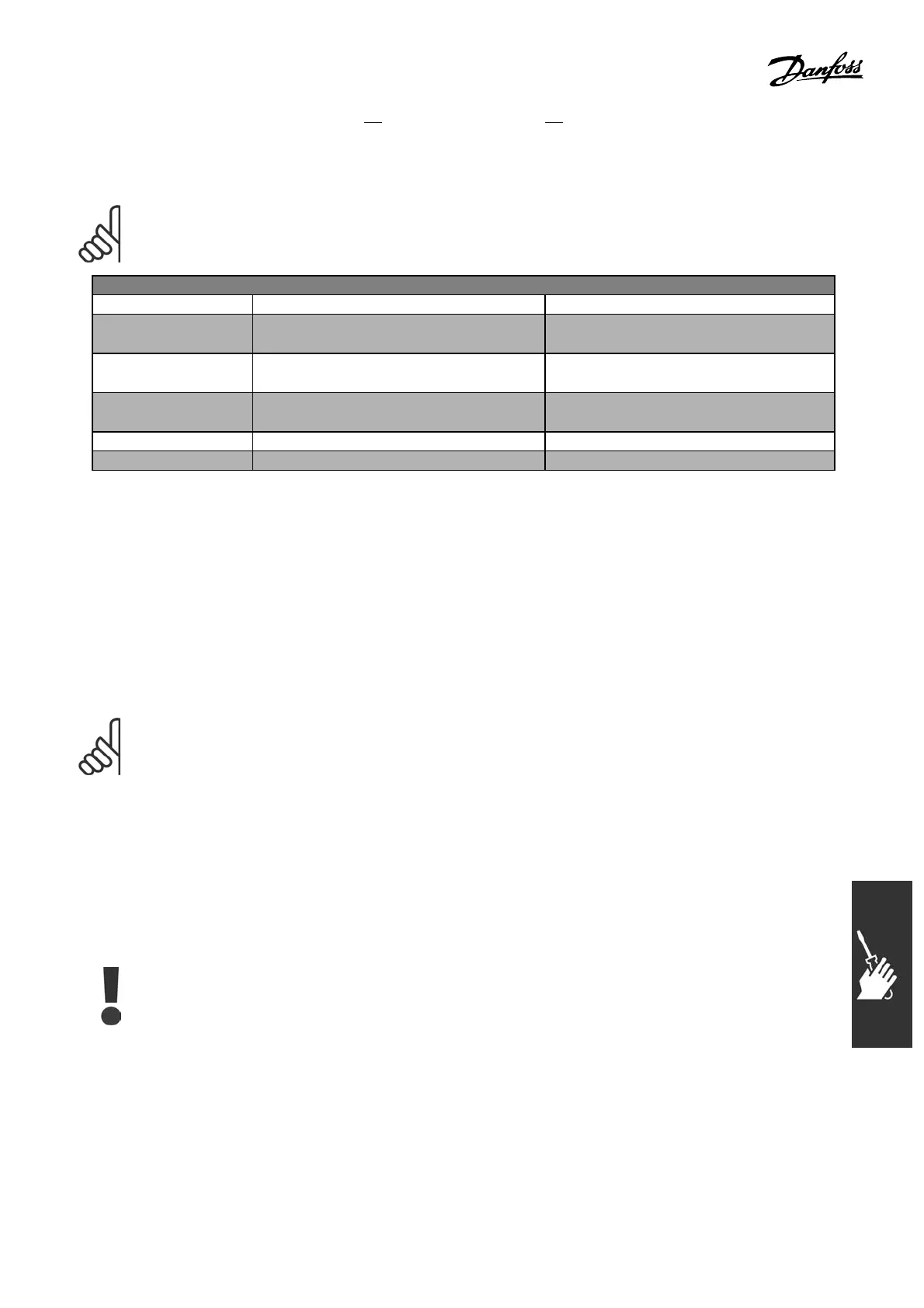

Tightening-up Torque

AFD size Cable for: Tightening-up torque

0.34-10 HP [0.25-7.5

kW]

Line, brake resistor, load sharing motor

cable

0.5-0.6 Nm

1.8 Nm

14.75-10 HP [11-15

kW]

Line, brake resistor, load sharing motor

cable

1.8 Nm

14.75-10 HP [11-15

kW]

Motor cable 1.8 Nm

Relay 0.5-0.6 Nm

Ground 2-3 Nm

" RemovalofKnockoutsforExtraCables

1. Remove the cable entry from the adjustable frequency drive (avoid foreign parts entering

the adjustable frequency drive when removing knockouts).

2. The cable entry must be supported around the knockout you intend to remove.

3. The knockout can now be removed with a strong mandrel and a hamm er.

4. Remove burrs from the hole.

5. Mount cable entry on adjustable frequency drive.

" Connection to Line Supply and Grounding

NOTE

The plug connec tor for power can

be removed.

1. Make sure the FC 300 is properly grounded.

Connect to ground connection (terminal 95).

Use screw from the accessor y bag.

2. Place plug connector 91, 92, 93 from the

accessory bag onto the terminals labele d

MAINS at the bottom of the FC 300.

3. Connect line wires to the line plug connector.

The ground conne ction cable cross-section

must be at least 3 .9 in

2

[10 mm

2

]or

have 2 rated line supp ly wires terminated

separately according to EN 50178.

The line supply connection is fitted to the line

supply switch if this is included.

97

MG.33.B6.22 - VLT is a registered Danfoss trademark

Loading...

Loading...