FC 300 Design Guide

How to Program

" Control Word Accord ing to FC Pro file (CTW)

To select the FC protocol in the control word, set

par. 8-10 control word profile to FC protocol [0].

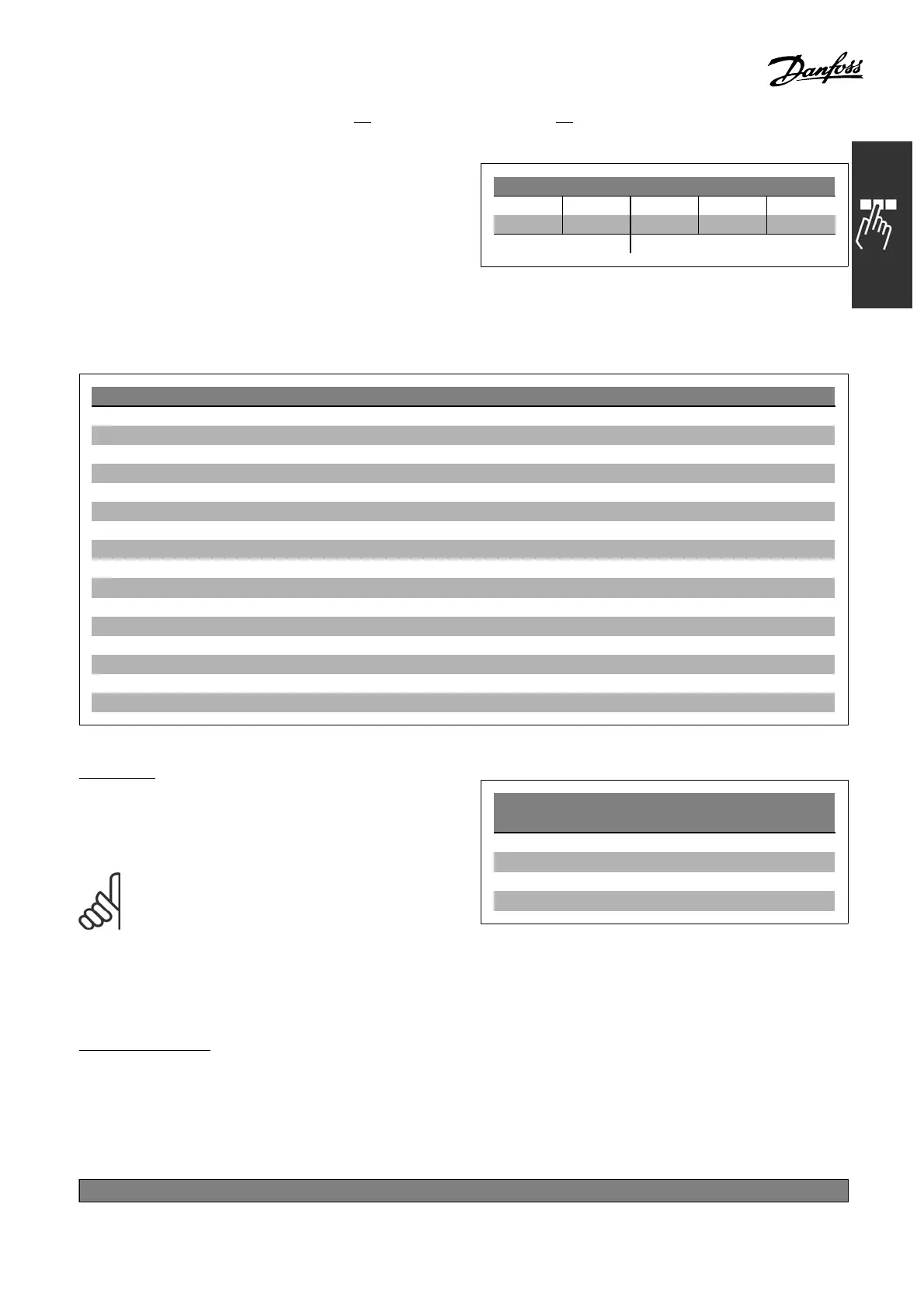

The control sends commands from a master (PLC

or PC) to a slave (adj. frequency drive).

Master => slave

1 2 3 ..... 10

CTW MRV PCD ..... PCD

PCD read/write

Explanation of the Control Bits

Bit Bit value = 0 Bit value = 1

00 Reference value e x ternal selection lsb

01 Reference value external selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Freeze output use ramp

06 Ramp stop Start

07 No func tion Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data not valid Data valid

11 Relay 01 open Relay 01 active

12 Relay 02 open (FC 302 only) Relay 02 active (FC 302 only)

13 Pa rameter set-up selection lsb

14 Parameter set- up selection msb

15 No func tion Reverse

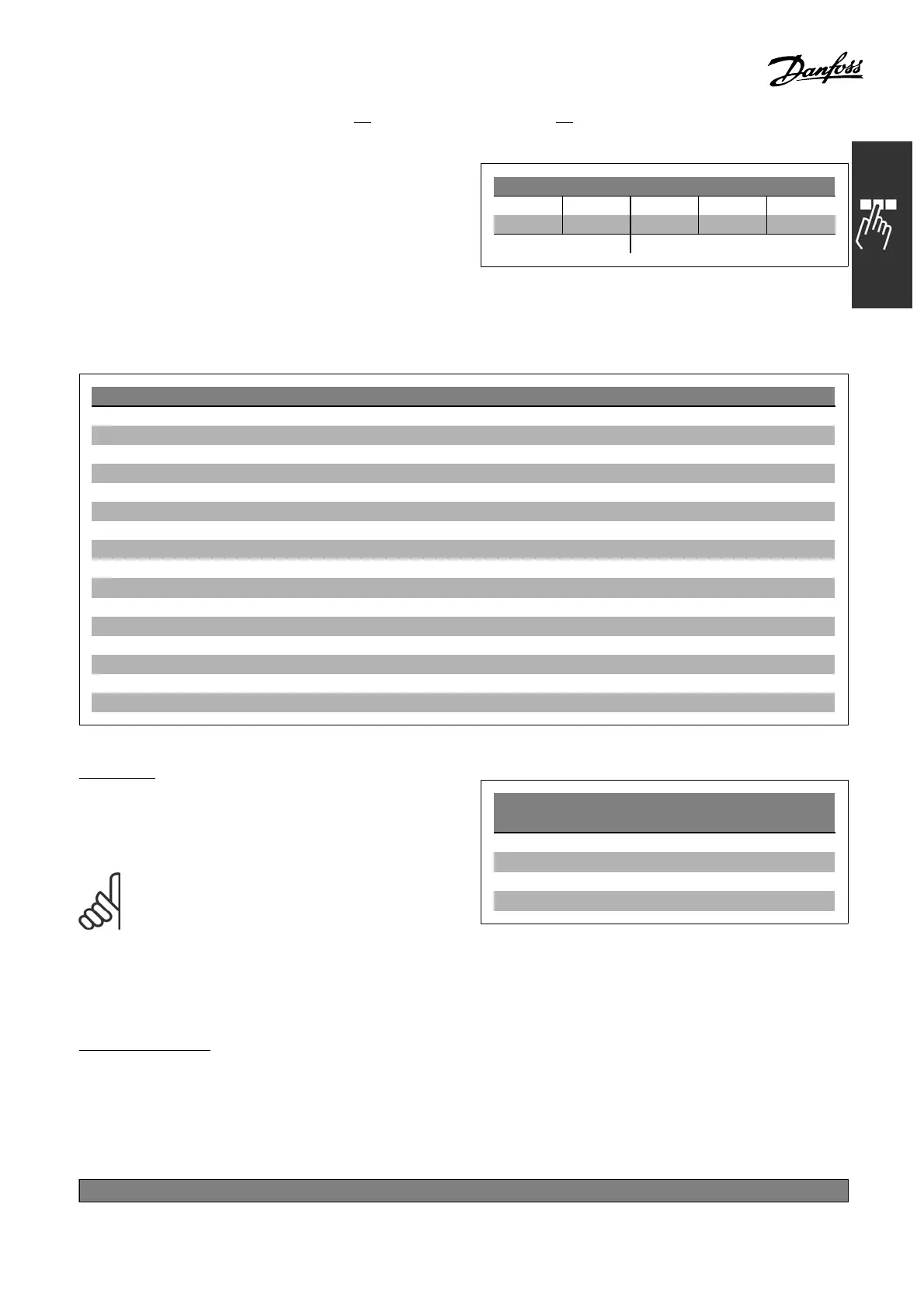

Bits 00/01

Usebits00and01tochoosebetweenthefour

reference values, which are pre-programmed

in par.

3-10 Preset Reference according to the shown table:

NOTE

Make a selection in par. 8-56 Preset

Reference Select to define how bit

00/01 gates with the corre sponding

function on the digital inputs.

Programmed ref.

value

Par. Bit 01 Bit 00

13-10[0]00

23-10[1]01

33-10[2]10

43-10[3]11

Bit 02, DC brake:

Bit 02 = ’0’: DC braking and stop. Set braking current and d uration in par. 2 -01 DC Brake

Current and 2-0 2 DC Braking Time. Bit 0 2 = ’1’ leads to ramping.

*

default setting ()display text []value for use in communication via serial communication port

277

MG.33.B

6.22 - V LT is a registered Danfoss trademark

Loading...

Loading...