FC 300 Design Guide

How to Install

" Use of EMC-Correct Cables

Danfoss recommends braided shielded/armored cables to optimize EMC immunity of the

control cables a nd the EMC emission from the motor cables.

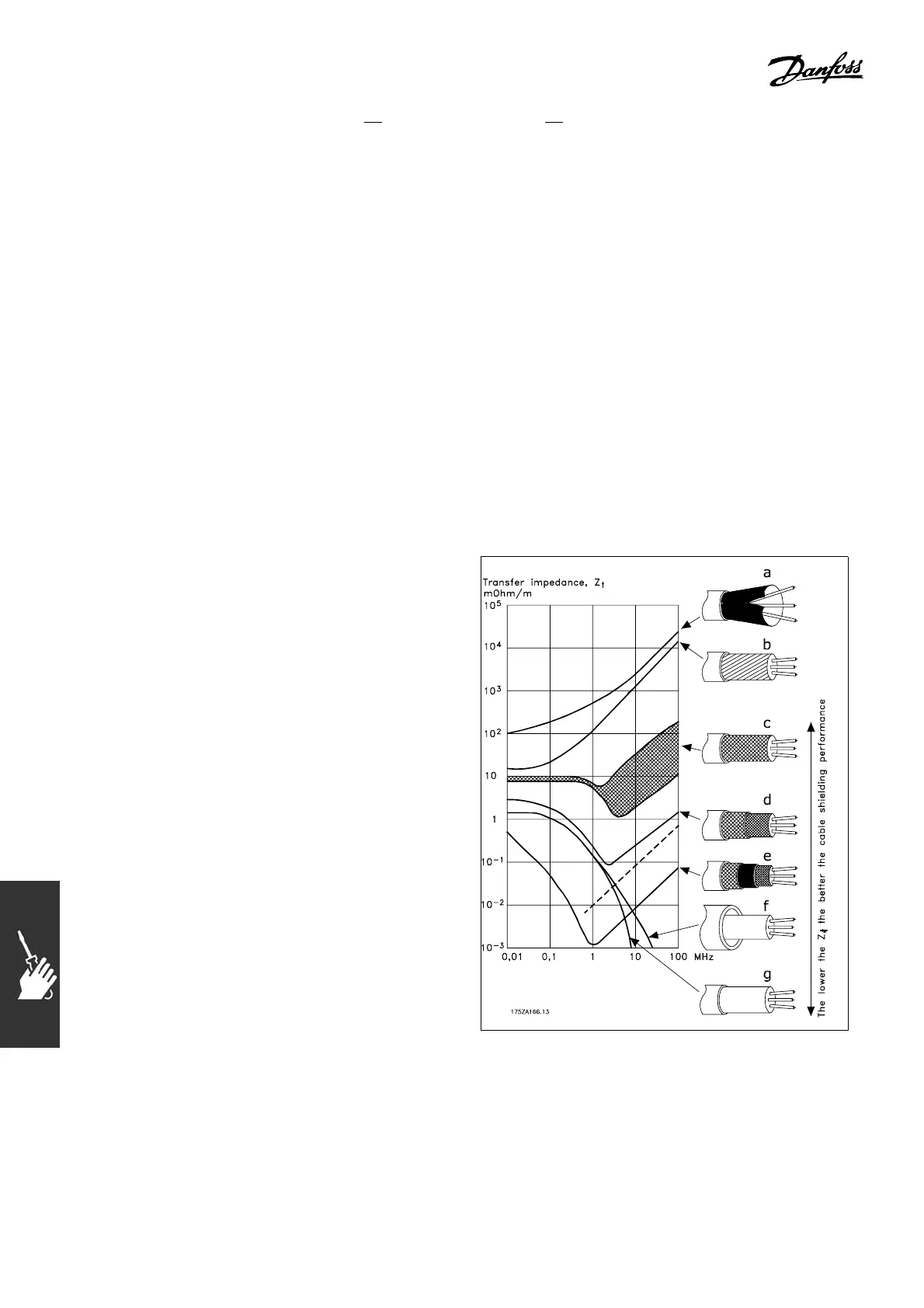

The ability of a cable to reduce the incoming and outgoing radiation of electric noise depends

on the transfer impedance (Z

T

). The shield of a cable is normally designed to reduce the

transfer of electric noise; however, a shield with a lower transfer imp ed ance (Z

T

)valueismore

effective than a shield with a higher transfer imped ance (Z

T

).

Transfer imp edance ( Z

T

) is rarely stated by cable manufacturers but it is often possible to estima te

transfer impedance (Z

T

) by assessing th e physical design o f the cable.

Transfer impedance (Z

T

) can be asse ssed on the basis of the following factor s:

- The conductibility of the shield material.

- The contact resistance between the individual shield conductors.

- The shield coverage, i.e. the physical area of the cable covered by the shield -

often stated as a percentage value.

- Shield type, i.e. braided or twisted pattern.

a. Aluminum-clad with cop per wire.

b. Twisted copper w ire or armored steel wire cable.

c. S ing le-layer braided copper wire with varying

percentage shield coverage.

This is the typical Danfoss reference cable.

d. Double-layer braided copper wire.

e. Twin layer of braided cop per wire with a

magnetic, shielded/armored intermedia te layer.

f. Cable that runs in copper tube or steel tube.

g. Lead cable with 0.043 in. (1.1 mm )

wall thickness .

122

MG.33.B6.22 - VLT is a registered Danfoss trademark

Loading...

Loading...