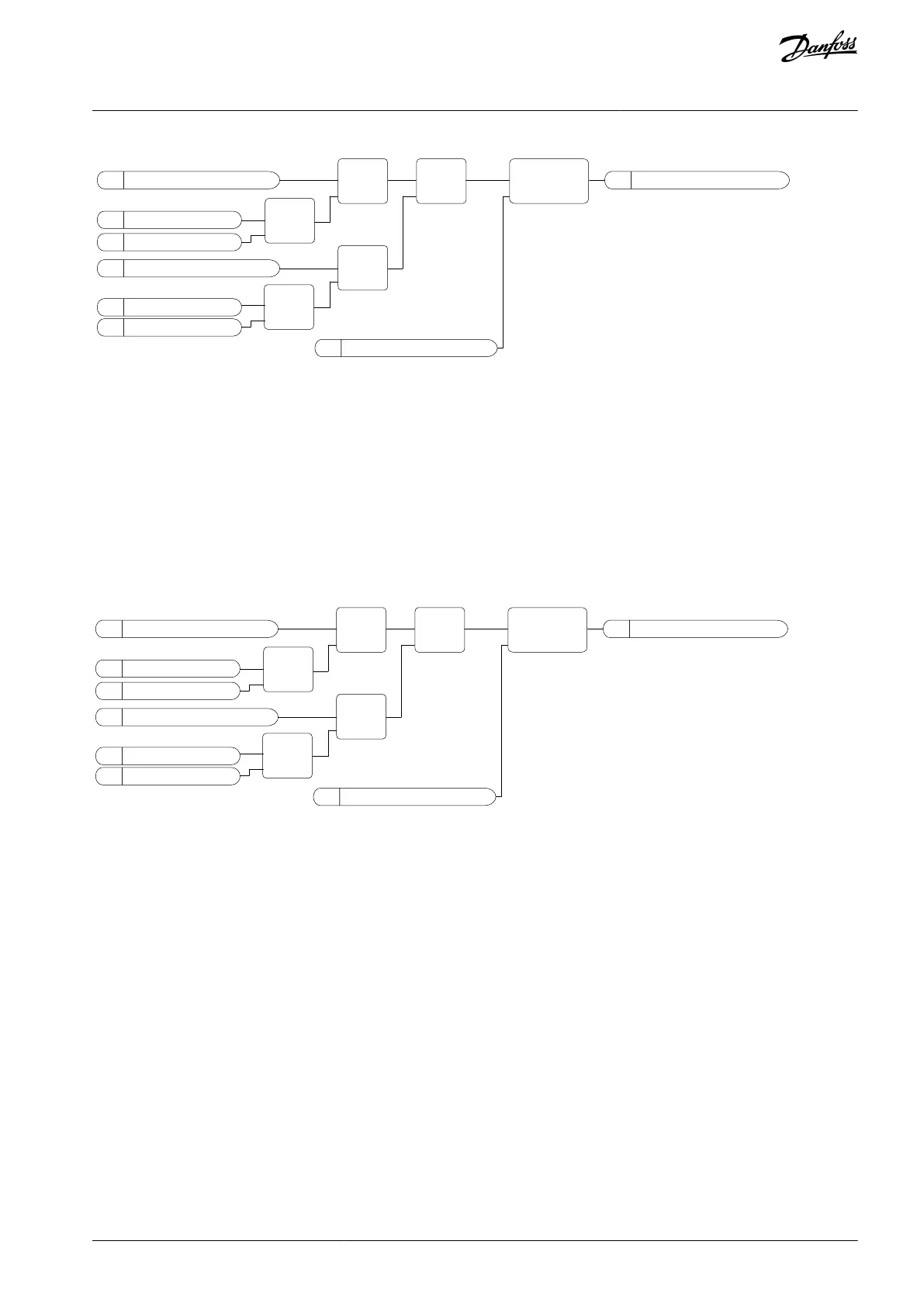

M

PID Feedback

P

Banwidth Delay

Start Aux Pump

V

M

Output Freq

M

PID Setpoint

P

Freq Ref Max

P

Staging Freq

P

Bandwidth

LT

IN1

IN2

GT

IN1

IN2

MIN

IN1

IN2

SUB

IN1

IN2

AND

IN1

IN2

ON-DELAY

IN OUT

TIME

e30bi988.10

Illustration 100: Staging Frequency

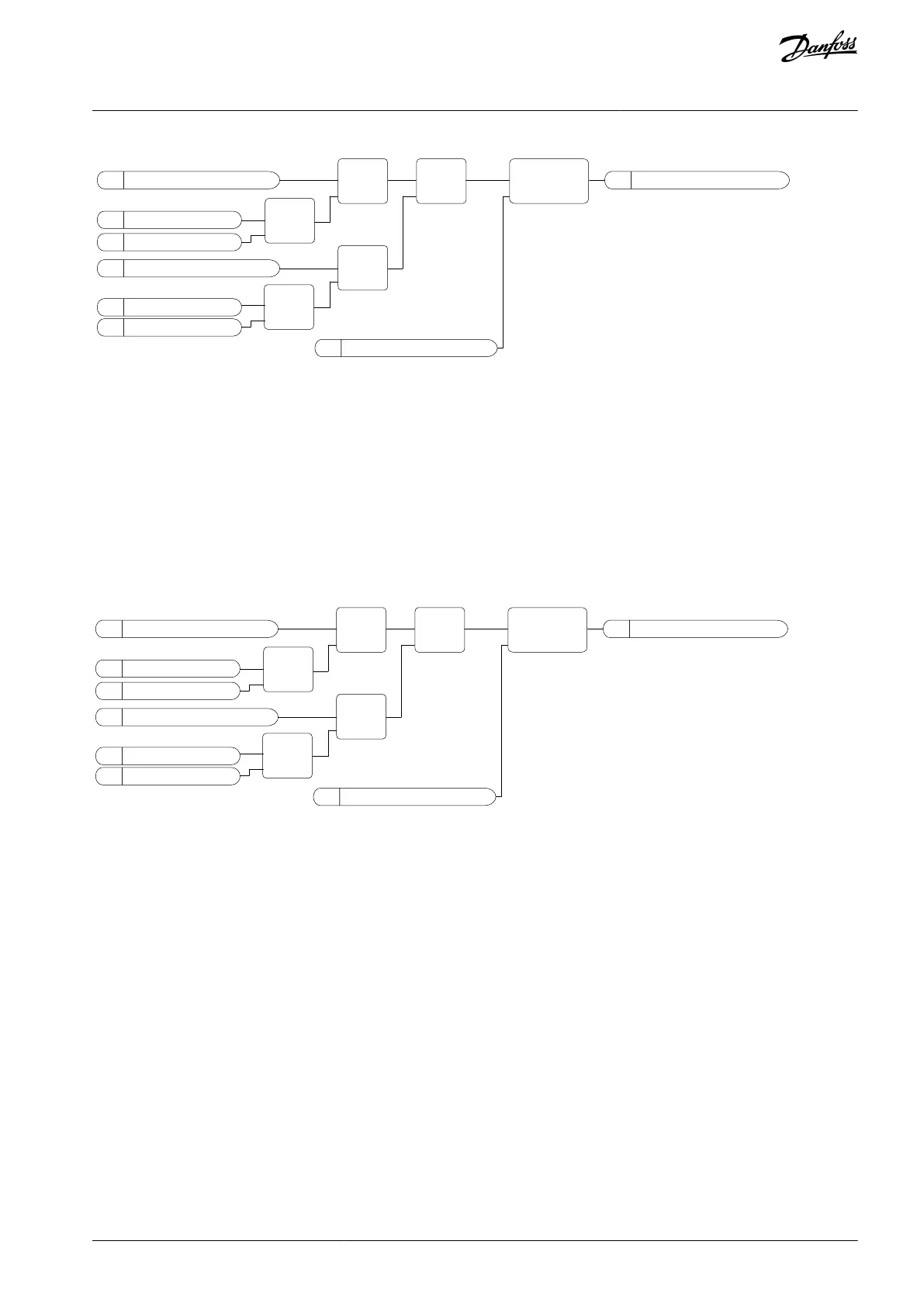

11.17.7.2 (ID 15546) Destaging Frequency

Location in the menu: P3.15.22.2

Use this parameter to adjust the output frequency level at which the auxiliary motor starts in the Multi-pump system.

The parameter has no effect, if its value is set below Min Frequency Reference (P3.3.1.1).

By default, an auxiliary pump stops (is destaged), if the PID feedback signal goes above the specified bandwidth area and the pump

that controls the system operates at the minimum frequency.

The auxiliary pump can stop at a higher frequency to get better process values or to use less energy. Then, use the parameter to set

the start frequency of the auxiliary pump above the minimum frequency.

M

PID Feedback

P

Banwidth Delay

Stop Aux Pump

V

M

Output Freq

M

PID Setpoint

P

Freq Ref Min

P

De-Staging Freq

P

Bandwidth

GT

IN1

IN2

LT

IN1

IN2

MAX

IN1

IN2

ADD

IN1

IN2

AND

IN1

IN2

ON-DELAY

IN OUT

TIME

e30bi989.10

Illustration 101: Destaging Frequency

11.17.7.3 (ID 15588) Staging Delay

Location in the menu: P3.15.22.3

Use this parameter to give a delay to start the next auxiliary pump in the Multi-pump system.

When PID feedback value goes below the bandwidth area, the time defined by this parameter must elapse before the next auxiliary

pump is started.

11.17.7.4 (ID 15589) Destaging Delay

Location in the menu: P3.15.22.4

Use this parameter to give a delay to stop auxiliary pump in the Multi-pump system.

When PID feedback value goes above the bandwidth area, the time defined by this parameter must elapse before the next auxiliary

pump is stopped.

11.18 Maintenance Counters

11.18.1 The Maintenance Counters

A maintenance counter tells that maintenance must be done. For example, it is necessary to replace a belt or to replace the oil in a

gearbox. There are 2 different modes for the maintenance counters, hours, or revolutions*1000. The value of the counters increases

only during the RUN status of the drive.

AB298035655957en-000201 / DPD01083 | 269Danfoss A/S © 2023.08

Parameter Descriptions

VACON® 100 FLOW

Application Guide

Loading...

Loading...