Setup & Operation 12. Option Slots

70 RC620 Rev.8

12.4.4 RS-232C Software Communication Setup (RS-232C)

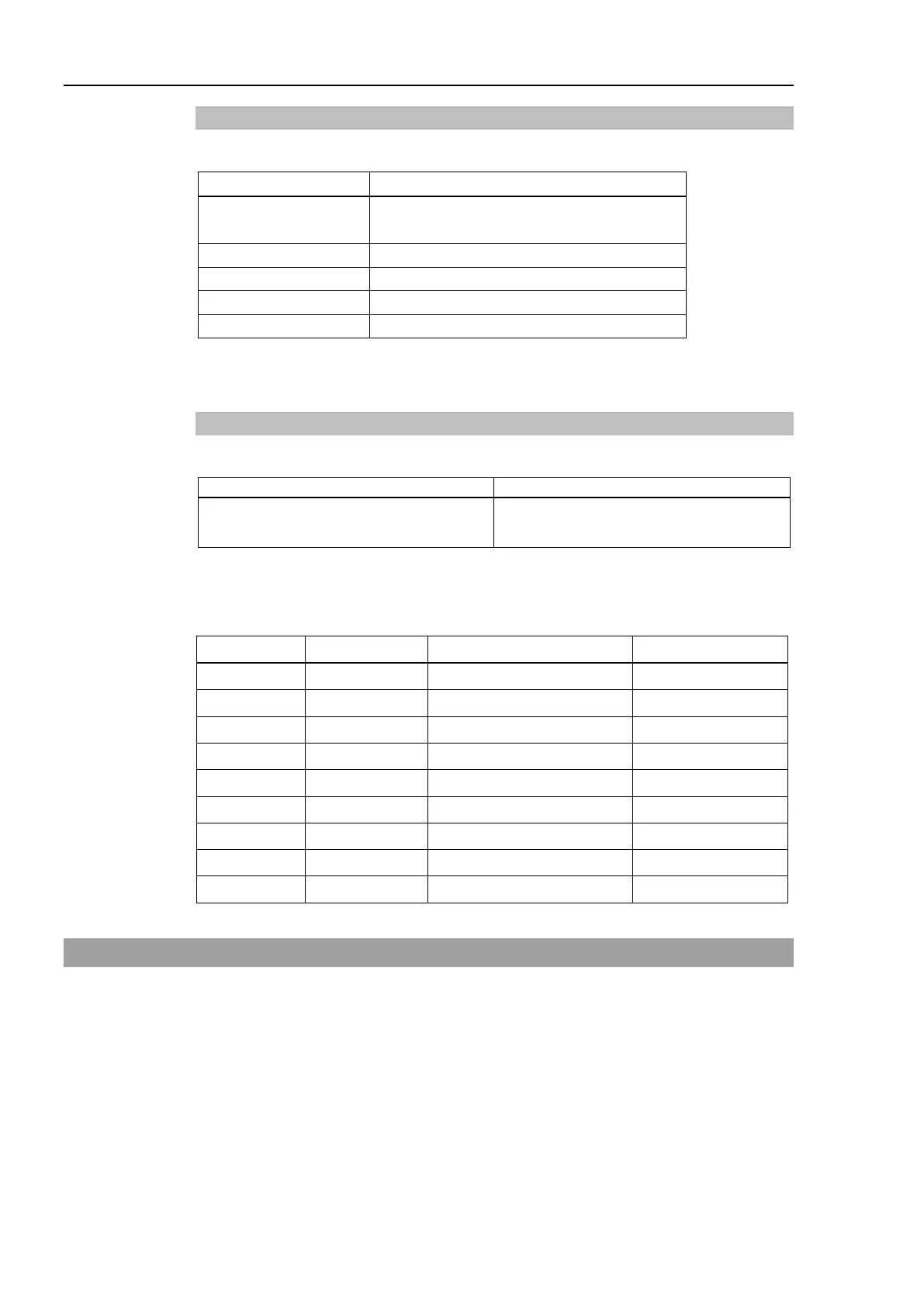

Available communication settings are as follows.

Baud Rates 110, 300, 600, 1200, 2400, 4800, 9600,

14400, 19200, 38400, 57600, 115200

Refer to EPSON RC+ 6.0 Online Help or 11. RS-232C Communications for RS-232C

communication from the Robot application.

12.4.5 Communication Cable (RS-232C)

Prepare a communication cable as described in this section.

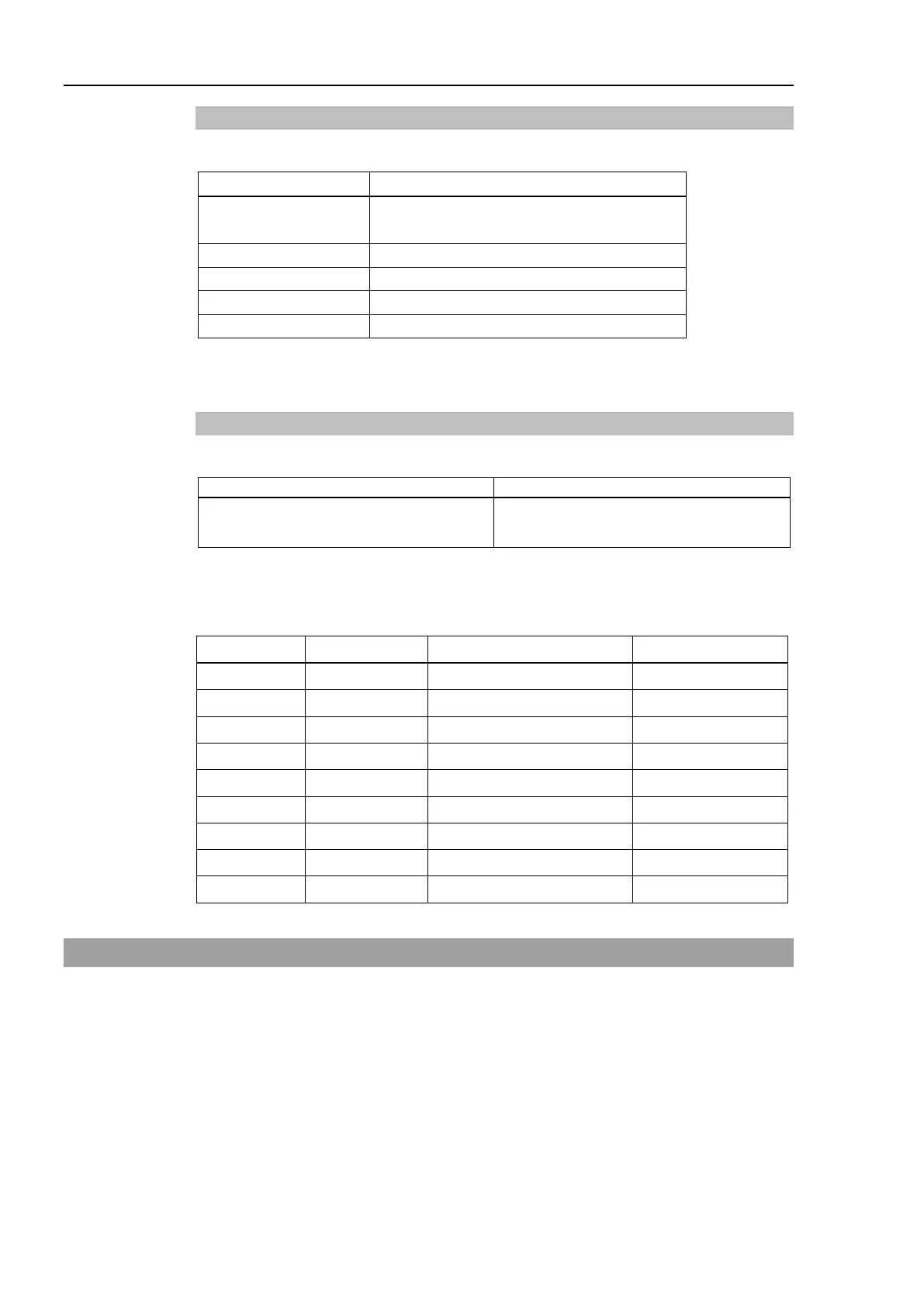

RS-232C Connector

(Controller side)

D-sub 9 male pin

Mounting style #4 - 40

Use twisted pair cable for shielded wire.

Clamp the shield to the hood for noise prevention.

Pin assign of the RS-232C connector is as follows.

Pin No Signal Function Signal Direction

1 DCD Data carrier detect Input

2 RXD Receive data Input

3 TXD Send data Output

4 DTR Terminal ready Output

5 GND Signal ground -

6 DSR Data set ready Input

7 RTS Request to send Output

8 CTS Clear to send Input

9 RI Ring indicator Input

12.5 PG Board

The PG board is used in the following 2 methods. For the details, refer to the each

manual.

- When used as the conveyor encoder

Refer to the EPSON RC+ 6.0 Users Guide 15. Conveyor Tracking.

- When used as the PG motion system

Refer to the RC620 Robot Controller option PG Motion System manual.

Loading...

Loading...