CHAPTER 79

PAGE 5

MAINTENANCE MANUAL EXTRA 330LX

PAGE DATE: 1. March 2011

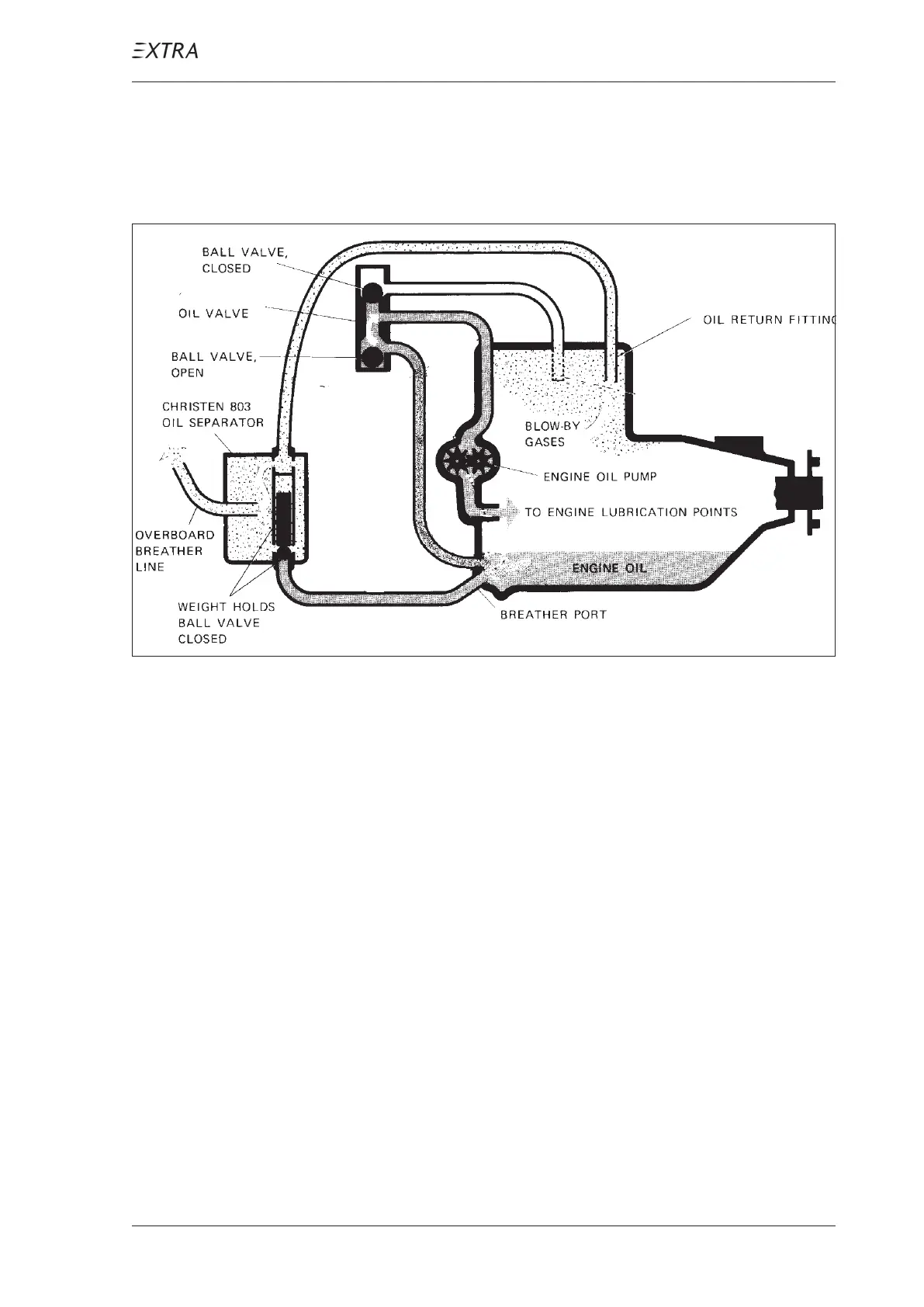

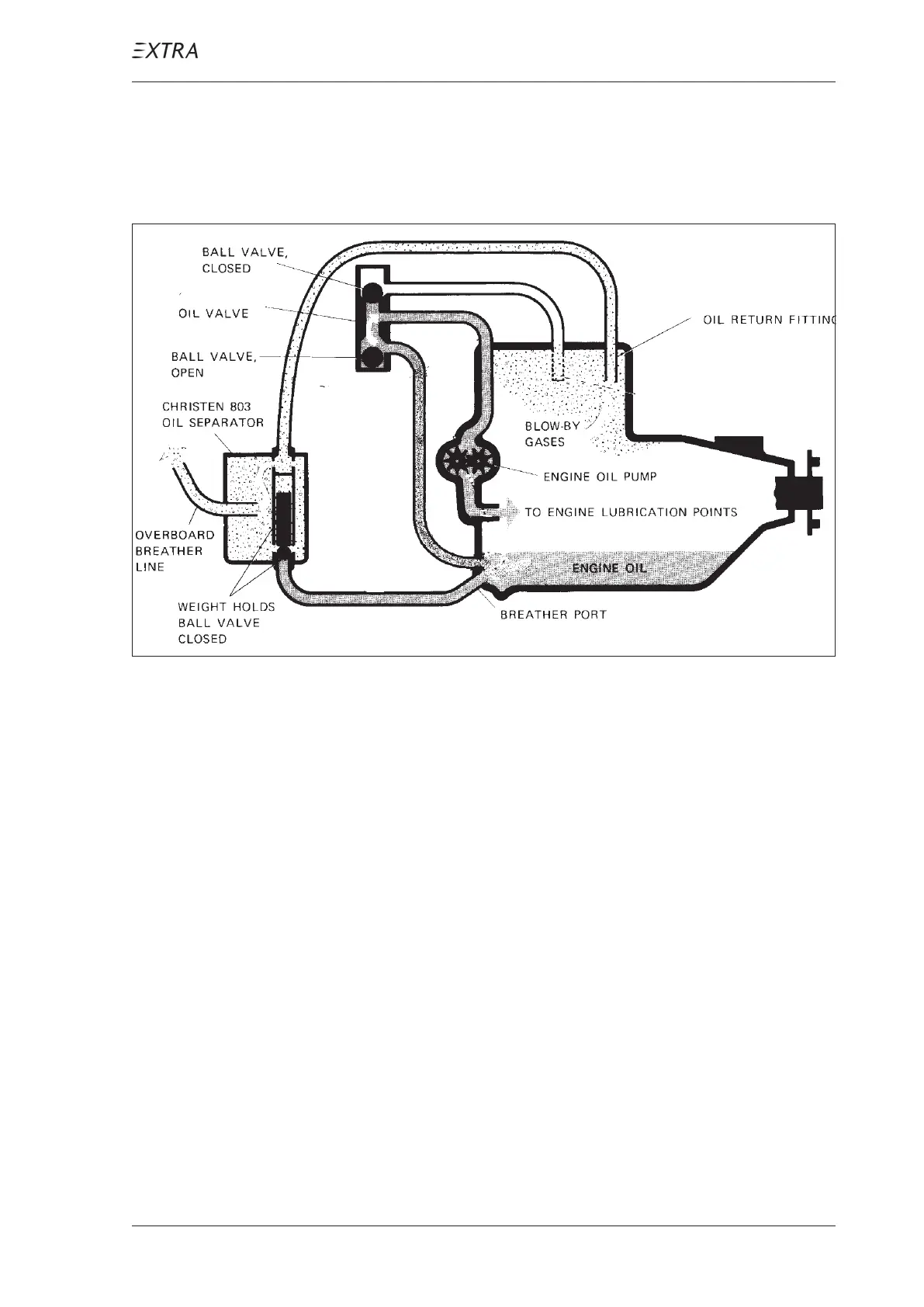

Any oil in the lines which fails to return to the sump during

the transition between normal and inverted flight drains into

the oil separator. This oil then returns to the sump from the

bottom of the oil separator during periods of normal flight.

Figure 2 Inverted Oil System, Inverted Flight

Maintenance Practices

The inverted oil system normally requires no maintenance.

During major overhauls or when repairs require sump re-

moval, inspect sump for excessive deposits of sludge, var-

nish, or foreign material. If sump is dirty, remove and

thoroughly clean all hoses and components; then use com-

pressed air blast for drying and cleanout before reassembly.

Cleaning

The inverted oil system must be flushed with a suitable

petroleum solvent, such as varsol, every 300 (three hundred)

hours of engine operation or when there is evidence of the

loss of oil through the breather line after normal flight.

Principles of Operation

INVERTED OIL SYSTEM

Loading...

Loading...