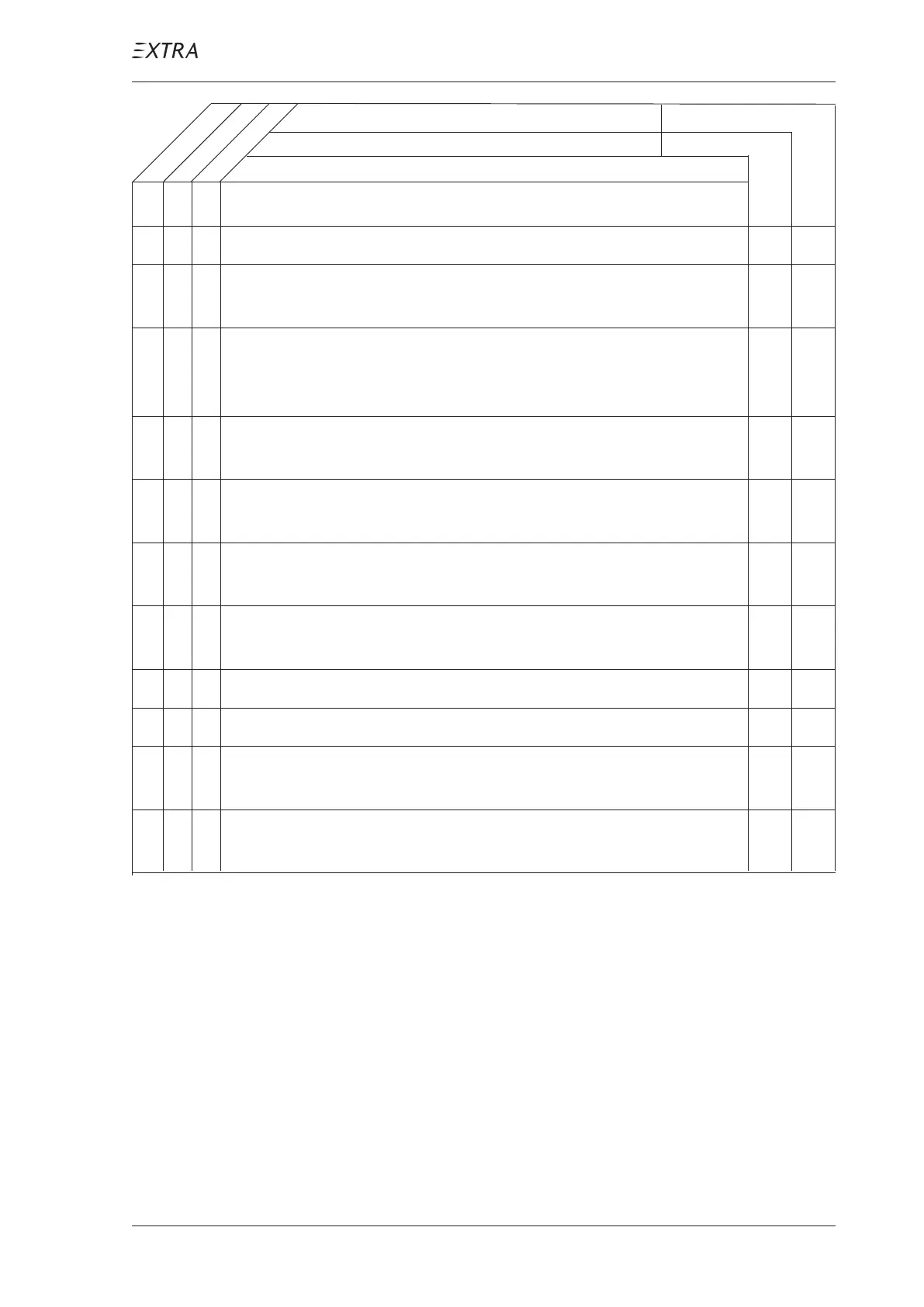

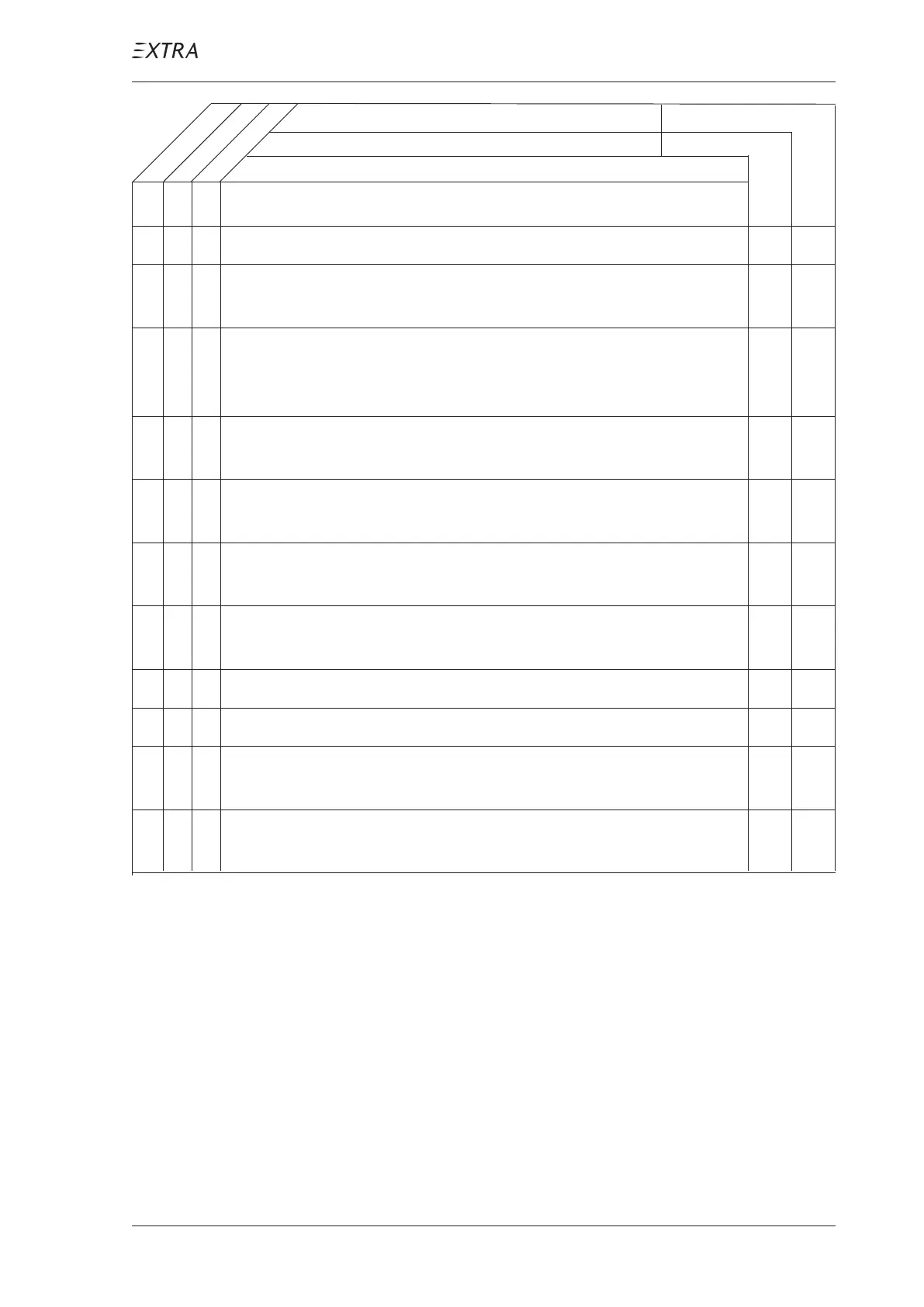

CHAPTER 5

PAGE 20

PAGE DATE: 1. March 2011

MAINTENANCE MANUAL EXTRA 330LX

Flight controls

O O 1 Remove wing access panels.

O O 2 Inspect control surfaces for security of attachment, free

movement, dents, delaminations and cracks.

O O 3 Check spades visually for general condition. Inspect spade

support for corrosion, cracks and deformations. Ensure

proper attachment to aileron.

O O 4 Inspect elevator trim system for proper operation and

rigging.

O O 5 Inspect hinges, hinge bolts, hinge bearings and self-locking

nuts for condition, cracks and security.

O O 6 Visual inspect bonding braid across the hinges for general

condition.

O O 7 Check free play in control system: torque tube, control

surfaces, control sticks, rod end bearings and travel stops.

O

1

O O 8 Lubricate rear torque tube bearing.

O O 9 Lubricate trim flap hinges and trim actuation lever bolts.

O 10 Check rudder cable system including sleeves, fairleads,

pulleys and cable retracting springs per FAA-AC 43.13-1A.

O O 11 Check PTFE tubes within the S-guidances at the rear seat

rudder pedals for general condition.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

1 each 25 hours

Loading...

Loading...