CHAPTER 5

PAGE 21

PAGE DATE: 14. August 2015

MAINTENANCE MANUAL EXTRA 330LX

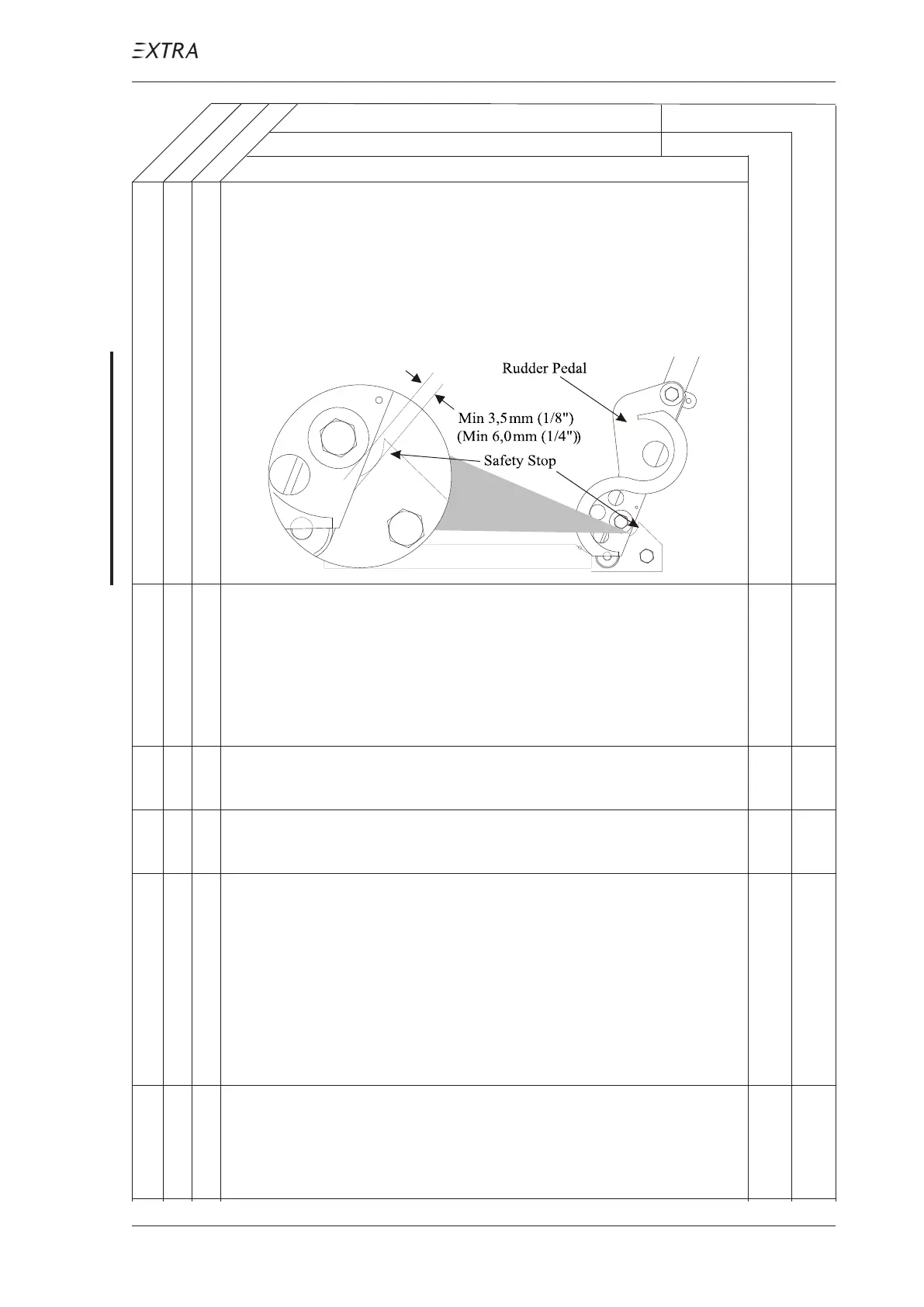

O 12 Check for minimum 3.5 mm (1/8") clearance of rudder

pedal versus safety stop when fully deflected for rudder

cables having 50 h flight time minimum. On newly installed

rudder cables the minimum spacing is 6 mm (1/4"). This

check is to be performed with zero loading on the rudder

pedals.

O 13 Rough check of safety stop clearance. With a force of

approx. 90 kg (200 lbs) acting on the fully deflected rudder

pedal the safety stop shall not be reached. If the stop is

reached the control system indicates too much flexibility

which needs to be traced. In this case contact EXTRA

Flugzeugproduktions- und Vertriebs- GmbH for advice.

O O 14 Inspect all flight control surface ventilation holes for ob-

struction.

O 15 Inspect elevator balance weights for looseness, clearance,

condition and interference with the composite structure.

O 16 Visually inspect metal push/pull control rods for corrosion,

loose or popped rivets, cracks, or other visible damage,

especially at their end fittings. In case of suspected cracks,

remove push/pull control rod, strip the paint in the sus-

pected area and carry out a detailed inspection using a

magnifying glass (x10). Replace the related control rod in

case a crack is found otherwise reapply surface treatment

and reinstall push/pull control rod.

O 17 Visually inspect fiber composite push/pull control rods for

cracks, impacts or other visible damage, especially at their

end fittings. No gap between aluminum head and rod is

allowed. Contact the manufacturer in case a gap is detected.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

each 50 hours

Loading...

Loading...