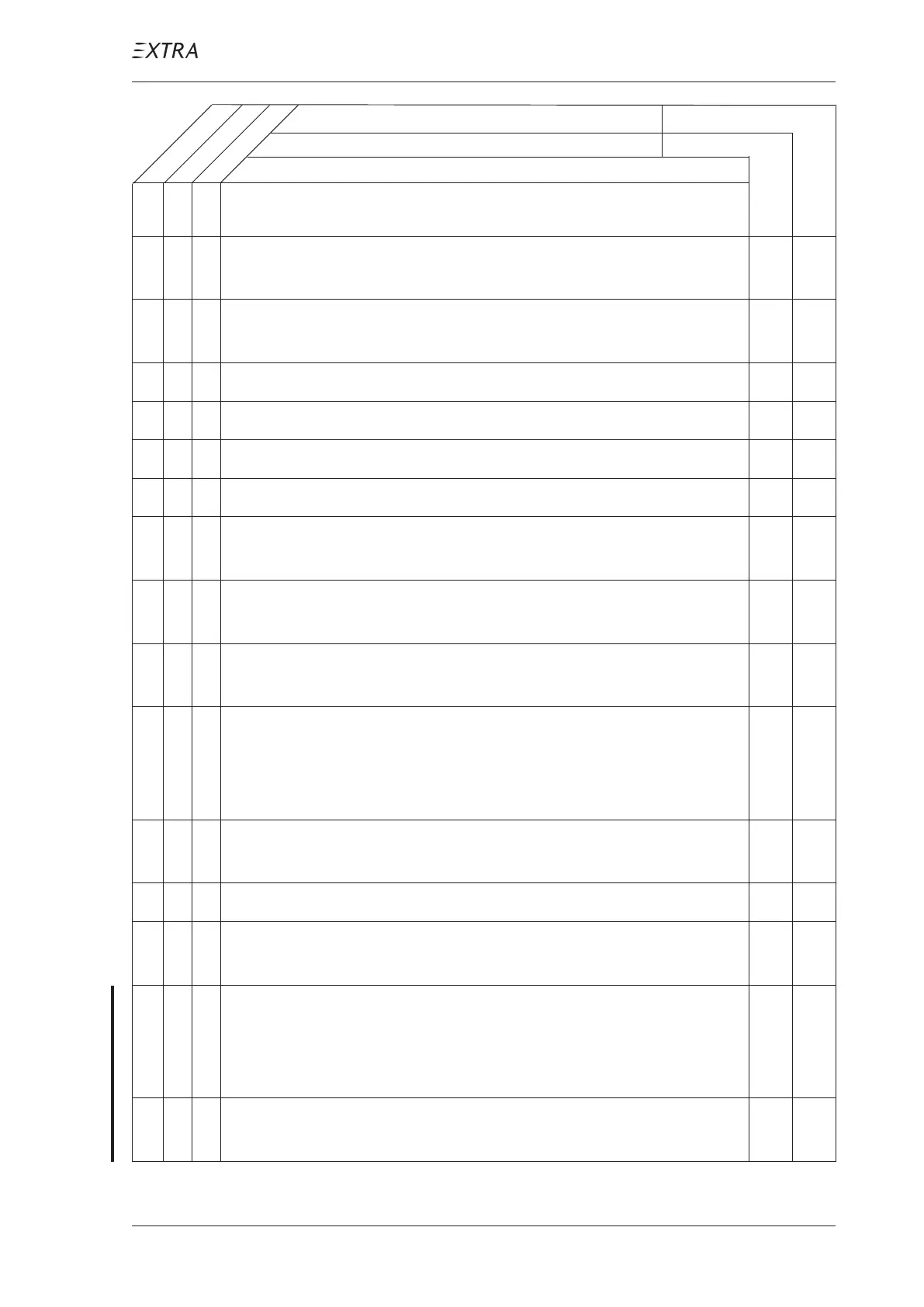

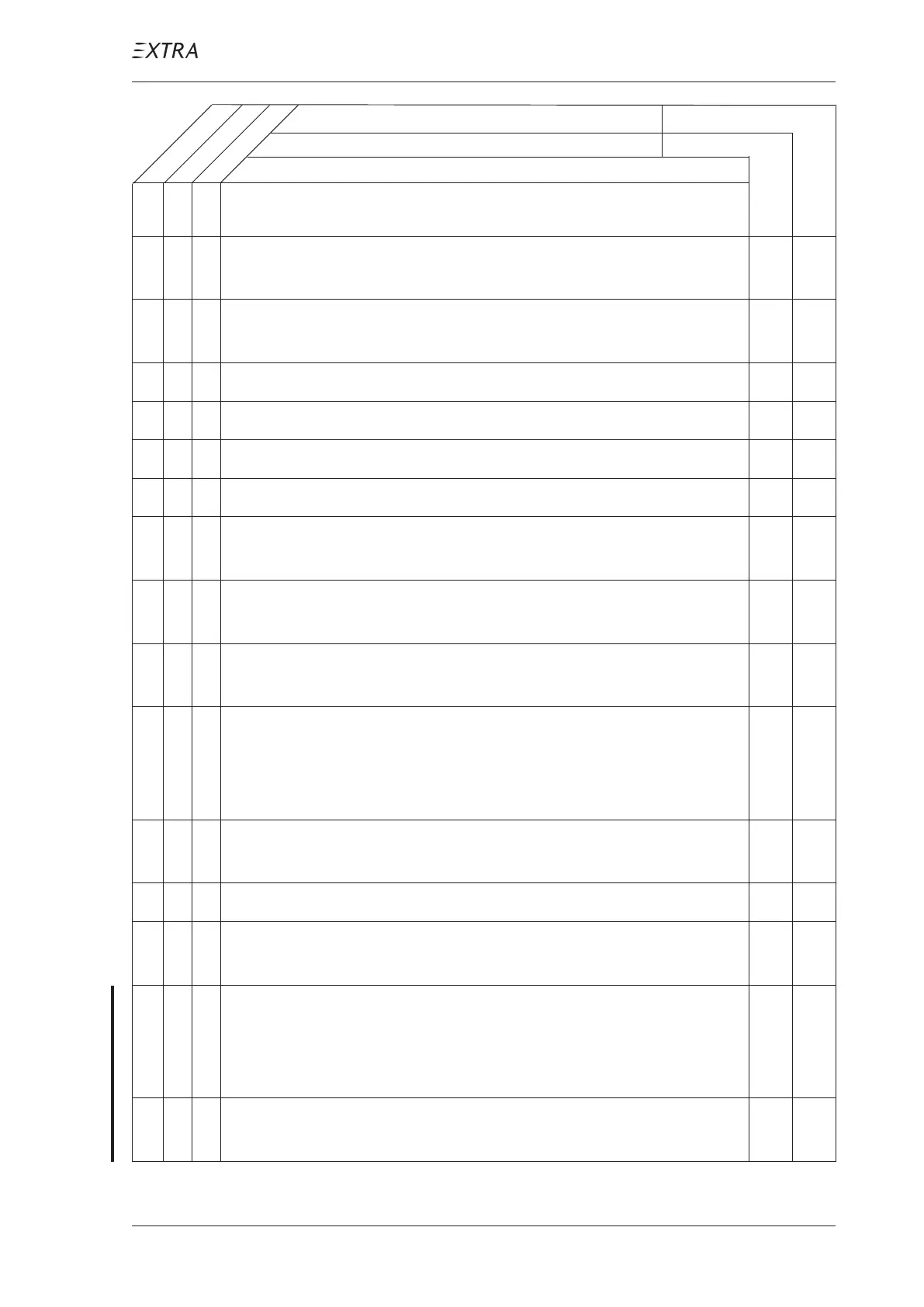

CHAPTER 5

PAGE 26

PAGE DATE: 1. March 2011

MAINTENANCE MANUAL EXTRA 330LX

Stabilizer

O O 1 Inspect stabilizer for dents, cracks, stone nicks and delami-

nations.

O O 2 Inspect main bolts of the stabilizer spars for looseness and

check security.

O O 3 Inspect stabilizer auxiliary spars attachment.

O 4 Inspect stabilizer ventilation holes for obstruction.

Instruments

O 1 Inspect panel mounting for security and safety.

O 2 Check operation, mounting, and wiring of switches for

condition and safety.

O 3 Check automatic circuit breaker mounting and wiring for

condition and safety.

O 4 Inspect stall warner system for condition and security of

installation, perform operational check.

O O 5 Check wing-tip position/strobe lights for security and

operation. If any one LED fails, the unit must be repaired or

replaced. Inspect the lens. Replace if there is excessive

scratching, discoloration or cracking.

O O 6 Inspect compass and compass deviation card for proper

indication and compensation.

O

1

7 Magnetic compass compensation.

O 8 Check Pitot/static air pressure lines for condition and

leaks, perform operational check.

O

1

9 Check ASPEN EFD1000 PFD and 1000 MFD (reversion

mode) speed bands for compliance with instrument mark-

ings in the Pilot's Operating Handbook. Correct data if

necessary per ASPEN Installation Manual.

O

1

10 Check ASPEN EFD(s) in accordance with Aspen ICA (Doc.

# 900-00012-001 latest Revision).

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

1 Annual, each twelve calendar months

PAGE DATE: 13. September 2013

Loading...

Loading...