Chapter 4 Installation and Wiring

PAGE 4-50

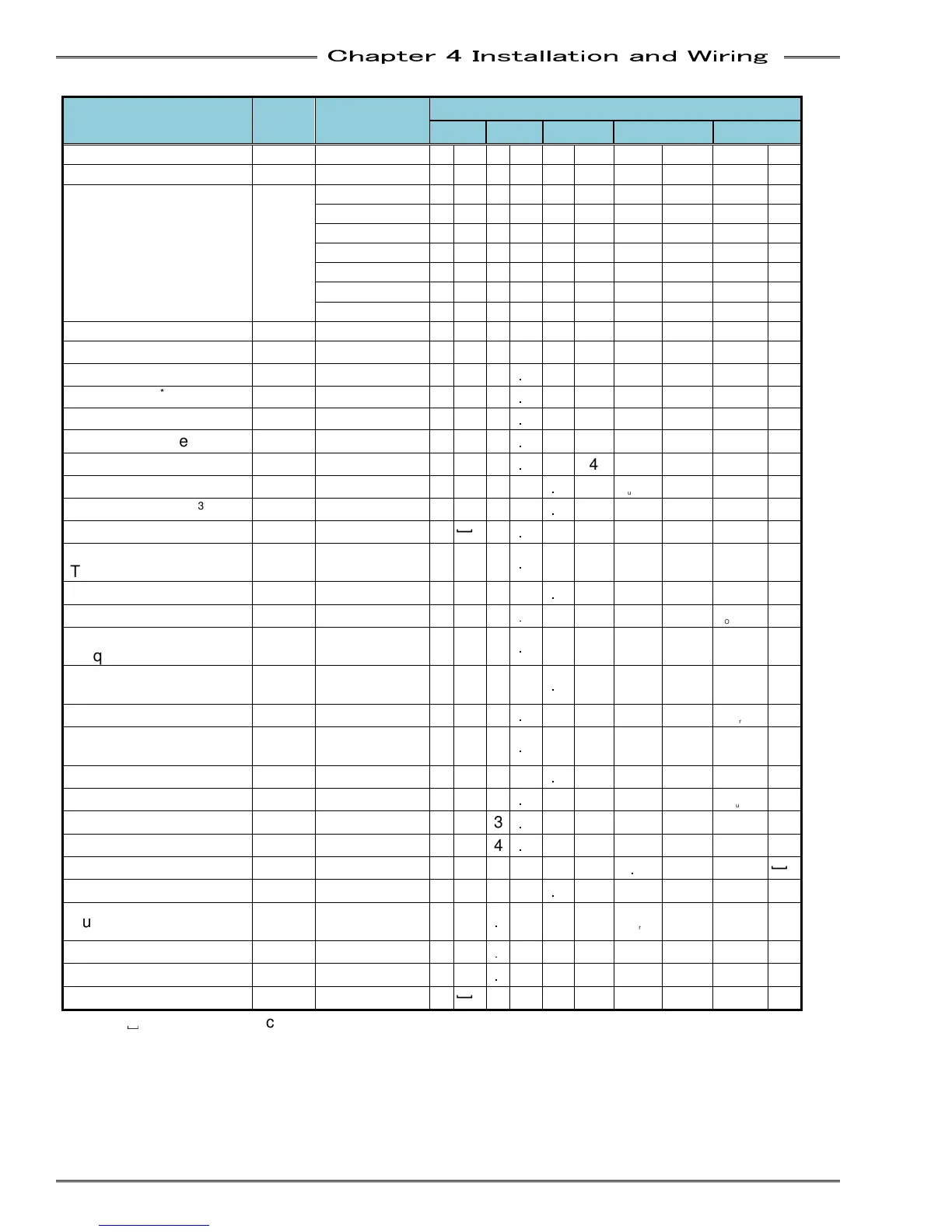

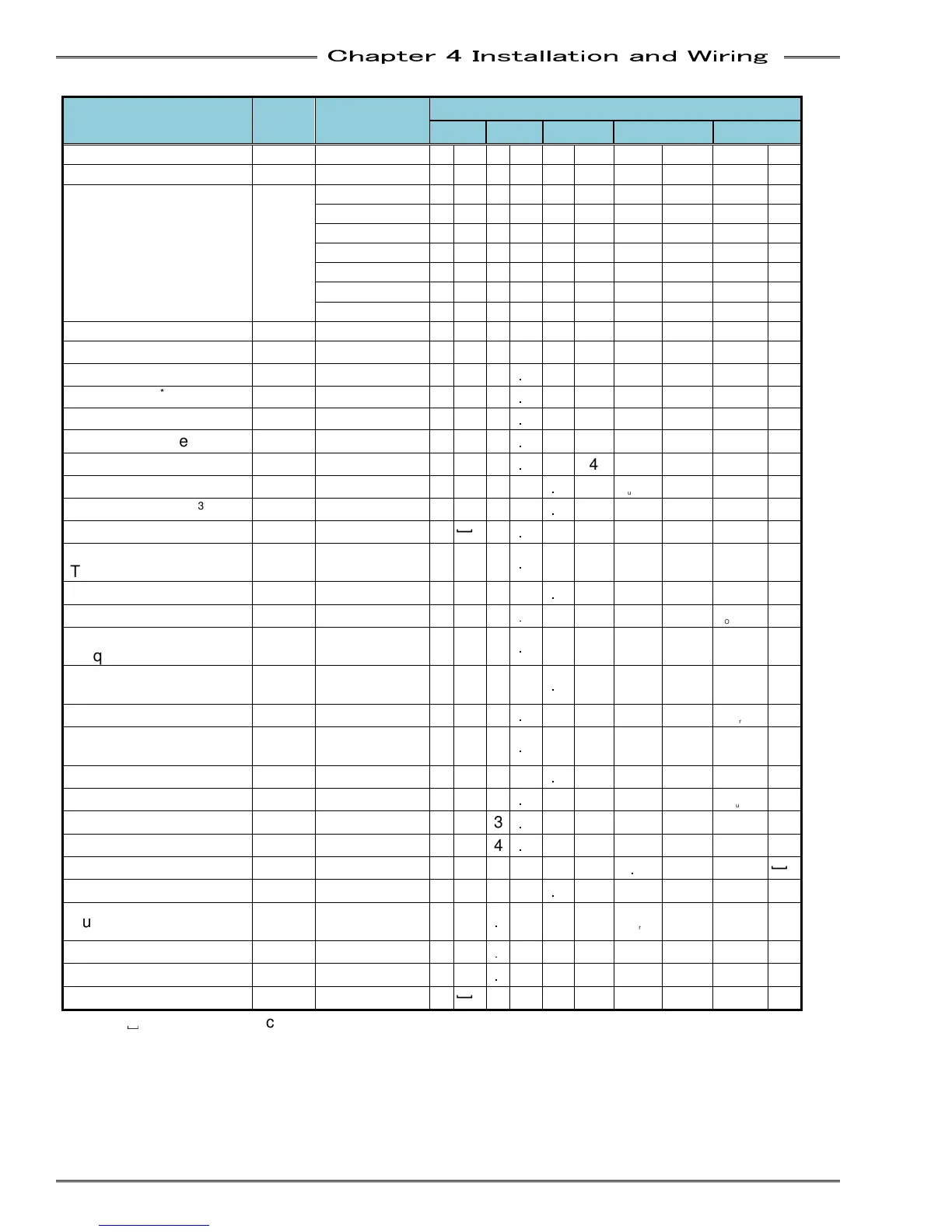

• Spindle data output format

Output Items

Number

of

Bytes

Fastening

Data

Axis Format

1word 2word

3word 4word 5word

Spindle No. (1 to 32)

2 1

1

PAR No. (1 to 32) 2 2

2

Spindle Judgment

*2

4

REJECT R

E J

]

ACCEPT A

C C

]

ABNORMAL A

B N

]

STOP S

T O

P

RESET STOP

R

S T

]

BYPASS B

Y P

]

START OFF S

O F

F

Spindle Cycle Count 8 123456

]

1

2 3 4 5 6

TOOL Cycle Count 8 12345678 1

2 3

4 5 6 7 8

Peak Torque

*3

8 12.34

1 2

.

3 4

Judgment Occurrence

Final Torque

*3

8 12.34

1 2

.

3 4

Judgment

Occurrence

SNUG Torque

*3

8 5.67

]

5

.

6 7

Judgment

Occurrence

1st Peak Torque 6 12.34

1 2

.

3 4

2nd Peak Torque 6 12.34

1 2

.

3 4

Final Angle

*3

8 123.4

1 2

3

.

4

Judgment

Occurrence

Differential Angle

*3

8 -12.3 -

]

1

2

.

3

Judgment

Occurrence

Rate 1

*3

10 1.234

]

1

.

2 3 4

Judgment

Occurrence

]

Rate 1 Increment

Torque

6 12.34

1 2

.

3 4

Rate 1 Increment Angle 6 123.4

1 2

3

.

4

Rate 2

*3

10 -0.123 -

]

0

.

1 2 3

Judgment

Occurrence

]

Rate 2 Increment

Torque

*3

6 12.34

1 2

.

3 4

Rate 2 Increment

Angle

*3

6 123.4

1 2

3

.

4

Rate 3

*3

10 0.123

]

0

.

1 2 3

Judgment

Occurrence

]

Rate 3 Increment

Torque

6 12.34

1 2

.

3 4

Rate 3 Increment Angle 6 123.4

1 2

3

.

4

1st Time

*3

10 123.456 1

2 3

.

4 5 6

Judgment

Occurrence

]

2nd Time

*3

10 123.456 1

2 3

.

4 5 6

Judgment

Occurrence

]

Cycle Time

*3

8 654.321 6

5 4

.

3 2 1

]

Peak Current

*3

10 12.3

]

]

1 2

.

3

Warning

]

Angle at Peak Torque 6 123.4

1 2

3

.

4

Rundown Revolutions

*3

8 12.34 1

2

3 4

Judgme

nt

Occurrence

]

ZERO Voltage 6 -0.123 -

0

1 2 3

CAL Voltage 6 3.512

3

5 1 2

Load rate

4 20

]

2

0

*1: “

␣

” (20H) is the space code (space).

*2: Please refer to “Spindle Judgment” (above in Single System setup explanation) regarding the

details of the Spindle judgment.

Loading...

Loading...