Chapter 7 Fastening Instructions

PAGE 7-29

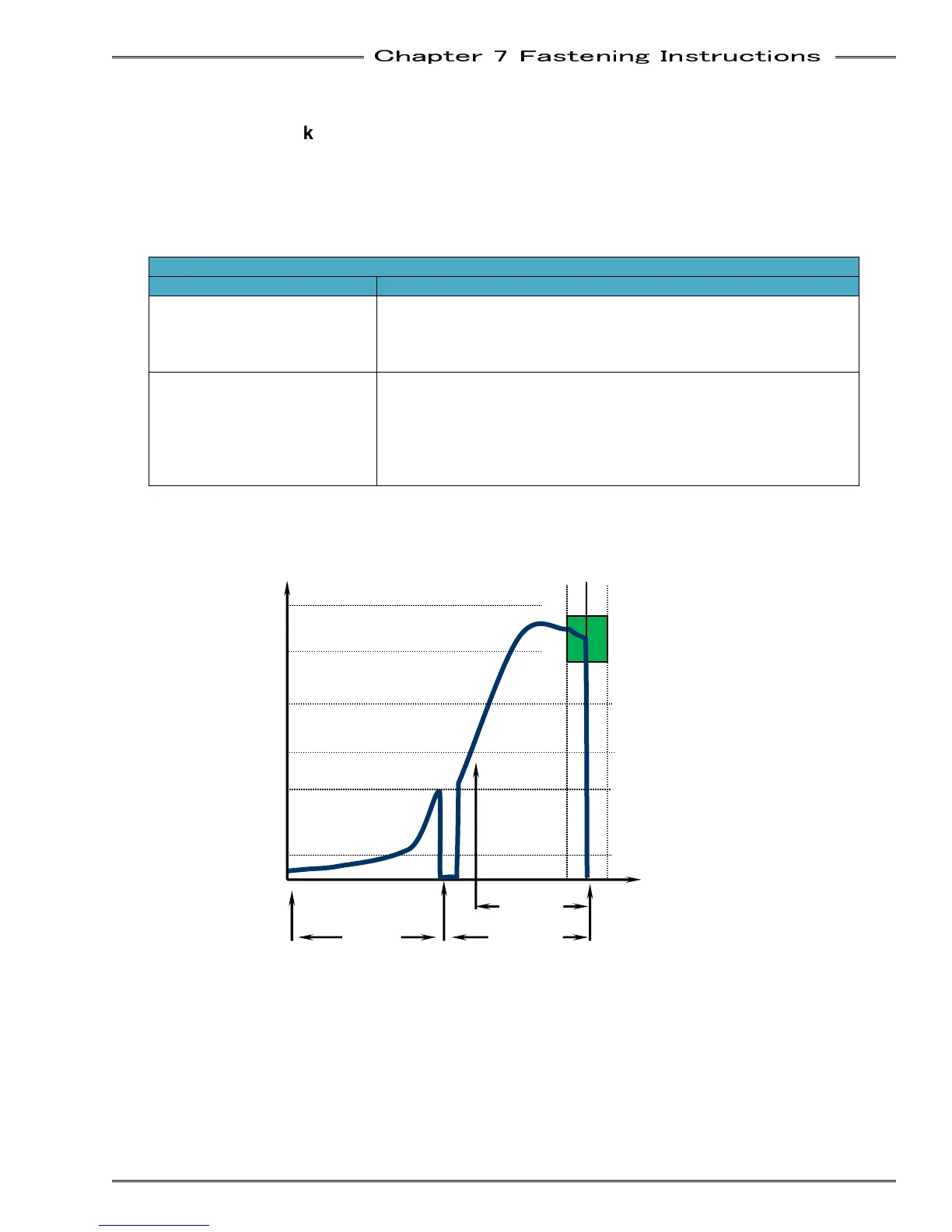

<Final Torque Check – Angle Control>

P

For Angle Control operations, the Torque value may reach a peak value and then drop to a lower

value as the fastener is stretched beyond the point of yielding. Final Torque High and Low Limits are

either set by the engineering specification for that specific fastener or by determining the acceptable

limits from a study of known good and bad assemblies.

FINAL TORQUE HIGH LIMIT

Reduced joint compression.

Increased joint friction.

Excessive chatter of the torque signal due to slip stick friction.

Incorrect parameter set-up.

FINAL TORQUE LOW LIMIT

Increased joint compression.

Reduced joint friction.

Excessive yield of fastener or broken fastener.

High initial prevailing torque.

Incorrect parameter set-up.

Reject condition caused by another monitor item reject.

Peak Torque High Limit

Peak Torque Low Limit

Torque

Angle/Time

Final Torque High Limit

Final Torque Low Limit

Ramp Down Start Torque

1

st

Torque

2

nd

Torque

2

nd

Time

1

st

Time

Standard

Angle

Loading...

Loading...