Chapter 3 System Description

PAGE 3-22

● Extension Tool Cable (Motor / Preamplifier / Resolver)

Offered in two types of cable: Standard Flex (Same cable as Main Cable) and High Flex.

Standard Flex is for normal flexing inside of cable tray, track and light duty shifting as long as

minimum bend radius is maintained.

High Flex is for higher flexing applications such as Robot and smaller cable track installations.

(High Flex cable is only offered in the Extension cable)

Standard Flex (Part #

:

FEB-1630E-Mx x = Length in meters) (2,3,5,6,7,7.5,10,12.5,15 Std. Lengths)

●Minimum bending radius

:

150mm

●Nominal Cable Diameter

:

16.0mm

High Flex (Part #

:

FEB-1630E-Mx-HF x = Length in meters) (2,3,5,6,7,7.5,10,12.5,15 Std. Lengths)

●Minimum bending radius

:

110mm

●Nominal Cable Diameter

:

14.5mm

Note: When using extension cables, it is recommended to keep total combined cable length no more

than 20meters (Main cable + extension cable) to reduce succeptibility to electrical noise.

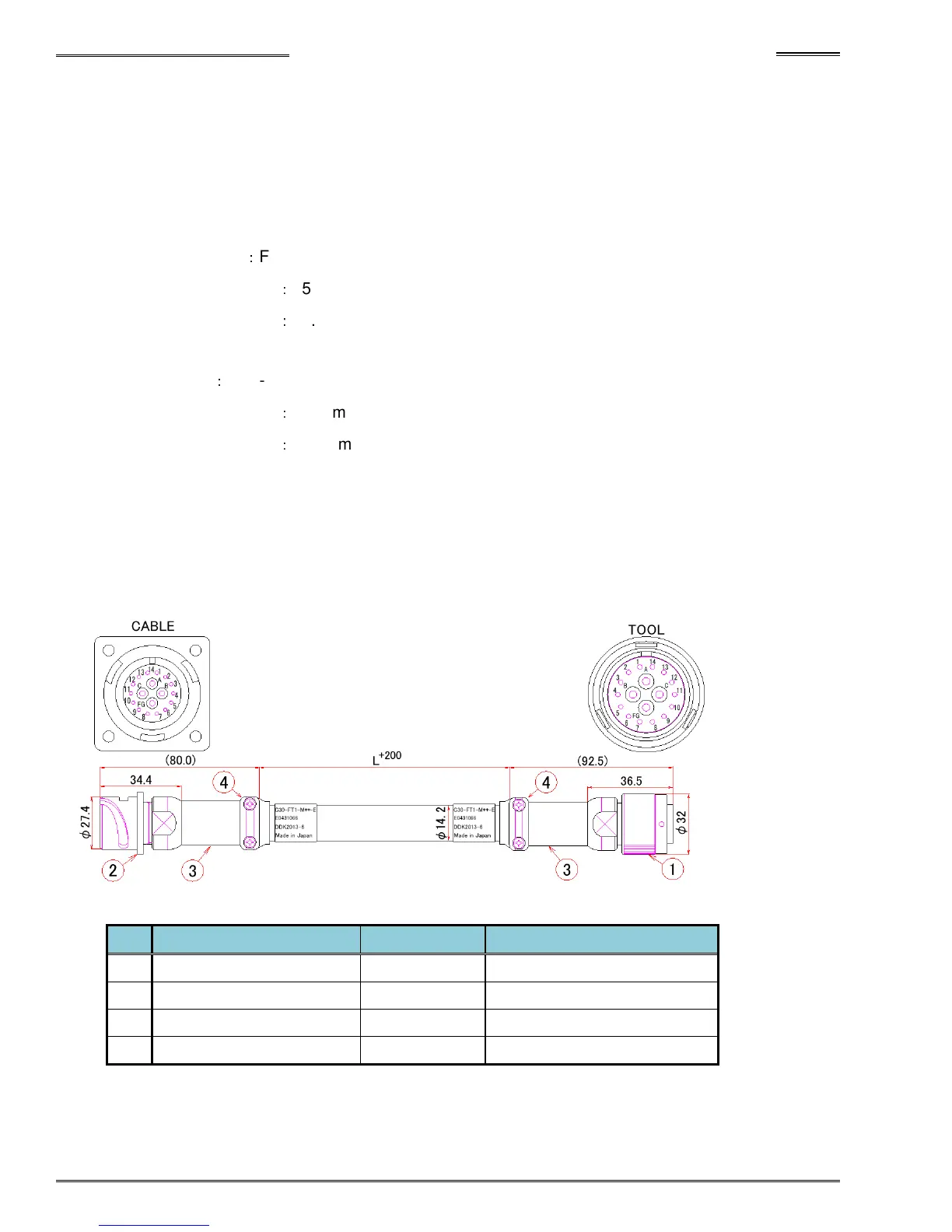

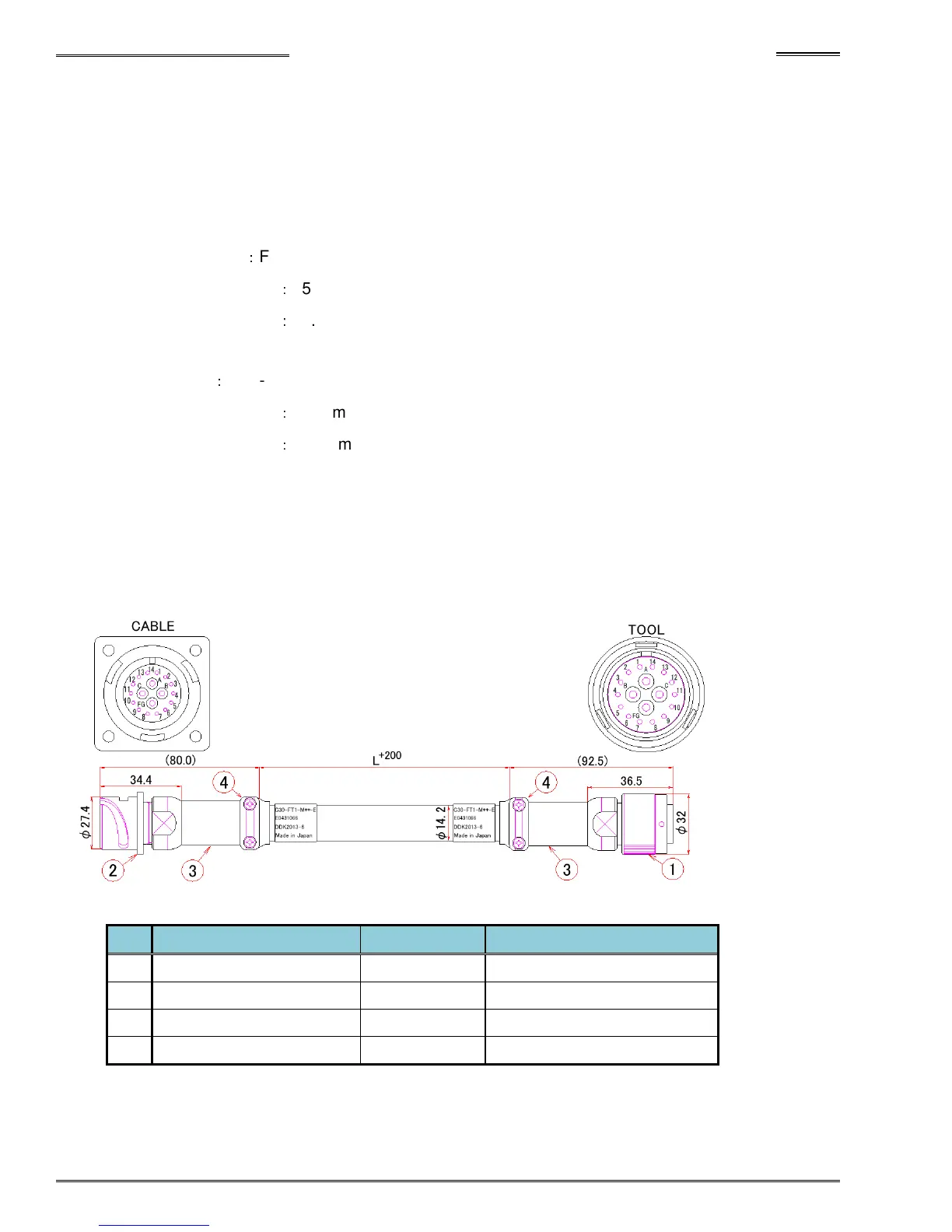

●Cable Drawing (Dimension units: mm)

● Connector Model

No. Type Manufacturer Model No.

1 Connector (Unit Side) DDK DCA3106A16-18BS-C

2 Connector (Cable Side) DDK DCA3102A16-18BPS-C(D32)

3 Molded Back FEC

4 Molded Back FEC

*Note: Connection is straight through – mirrored wiring of tool side main tool cable

Warning: The use of extension cables increase succeptablity of electrical noise to the signal

conductors inside the cable and therefore should be used with caution and only be used in

(electrical) noise-free enviroments.

Loading...

Loading...