ENGINE MANAGEMENT SYSTEM

- 357 -

After making sure that engine is cold, relieve fuel pressure as follows.

• Place vehicle gear in ‘Neutral’.

• Disconnect fuel module electrical coupler from vehicle harness.

• Start engine and run till it stops due to lack of fuel. Repeat ignition key ON and OFF for 2 ~ 3

times of about 3 seconds each time to relieve fuel pressure in lines. Fuel Connections are

now safe for servicing.

• Upon the completion of servicing, Connect Fuel Module Connector to Vehicle Harness.

7. Fuel Leakage Check Procedure:

After performing any service on fuel system, check to make sure that there are no fuel leakages

as below.

• Fill about 3 ~ 5 liters of fuel in tank.

• Turn Ignition key to ON position for 3 seconds (to operate fuel pump) and then turn to OFF

position. Repeat this for 3 ~ 4 times to apply fuel pressure in fuel lines.

• In this state, check to see that there are no fuel leakage from any part of fuel system (Fuel

Tank, Hoses, Hose Joints, etc)

8. Handling – DOs and DONTs:

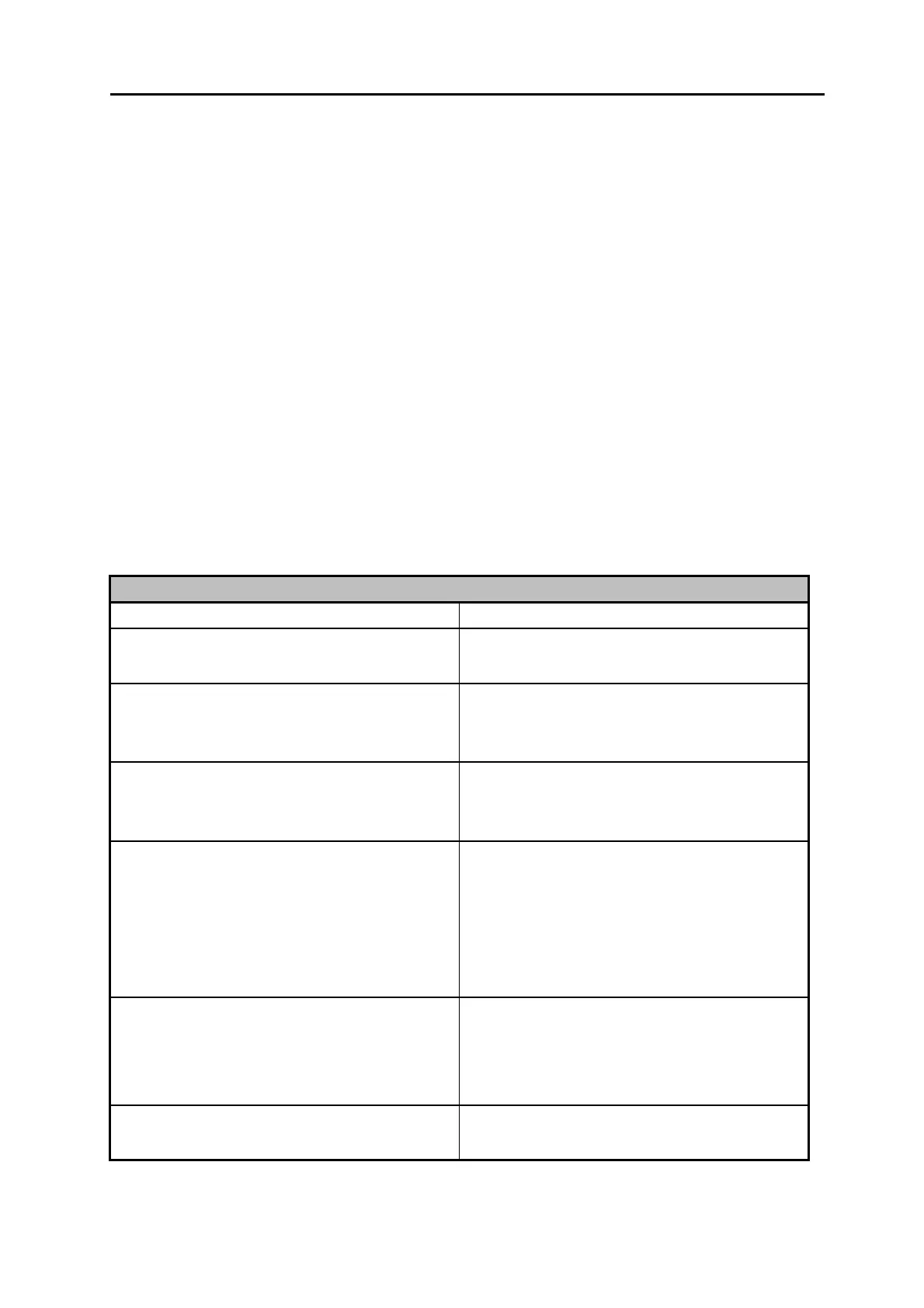

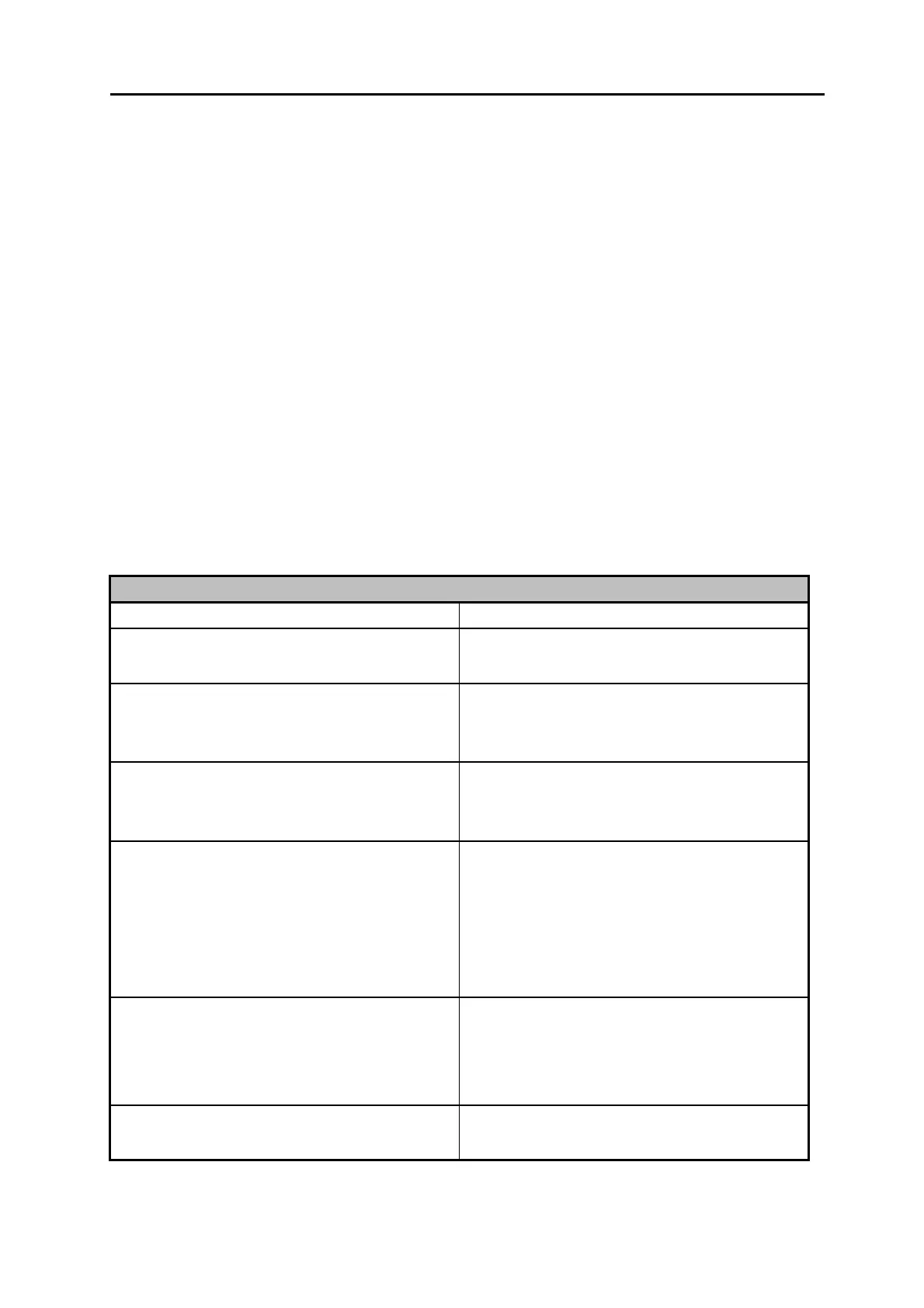

FUEL MODULE HANDLING

ACTION REASON

DO NOT: Drop Fuel Module on Floor Could cause internal damage to Fuel

Pump.

DO NOT: Run Fuel Pump Dry (without fuel

at pump inlet/ strainer) ensure atleast 3

litres of gasoline is present in the fuel tank

Caused internal damage to Fuel Pump

DO NOT: Damage the strainer during

servicing, insertion of fuel module in fuel

tank

Contamination enters fuel pump thru

damaged strainer damages the Fuel

Pump

DO NOT: Disassemble Fuel Pump and

regulator internal parts out side Delphi

premises.

DO NOT: Do any adjustments on pressure

regulator and pump except for

replacement.

Warranty void.

DO NOT: Use module harness for hold/

carry fuel module.

DO NOT: Pull Wiring Harness in vertical

direction to module cover

Wiring Harness Breakage/ Fuel Pump

Power disconnection

DO NOT: Use damaged/ distorted hose

clamps.

Can cause fuel seepage/ leakage.

Loading...

Loading...