HT2000H_en_n.doc Page 136 of 167

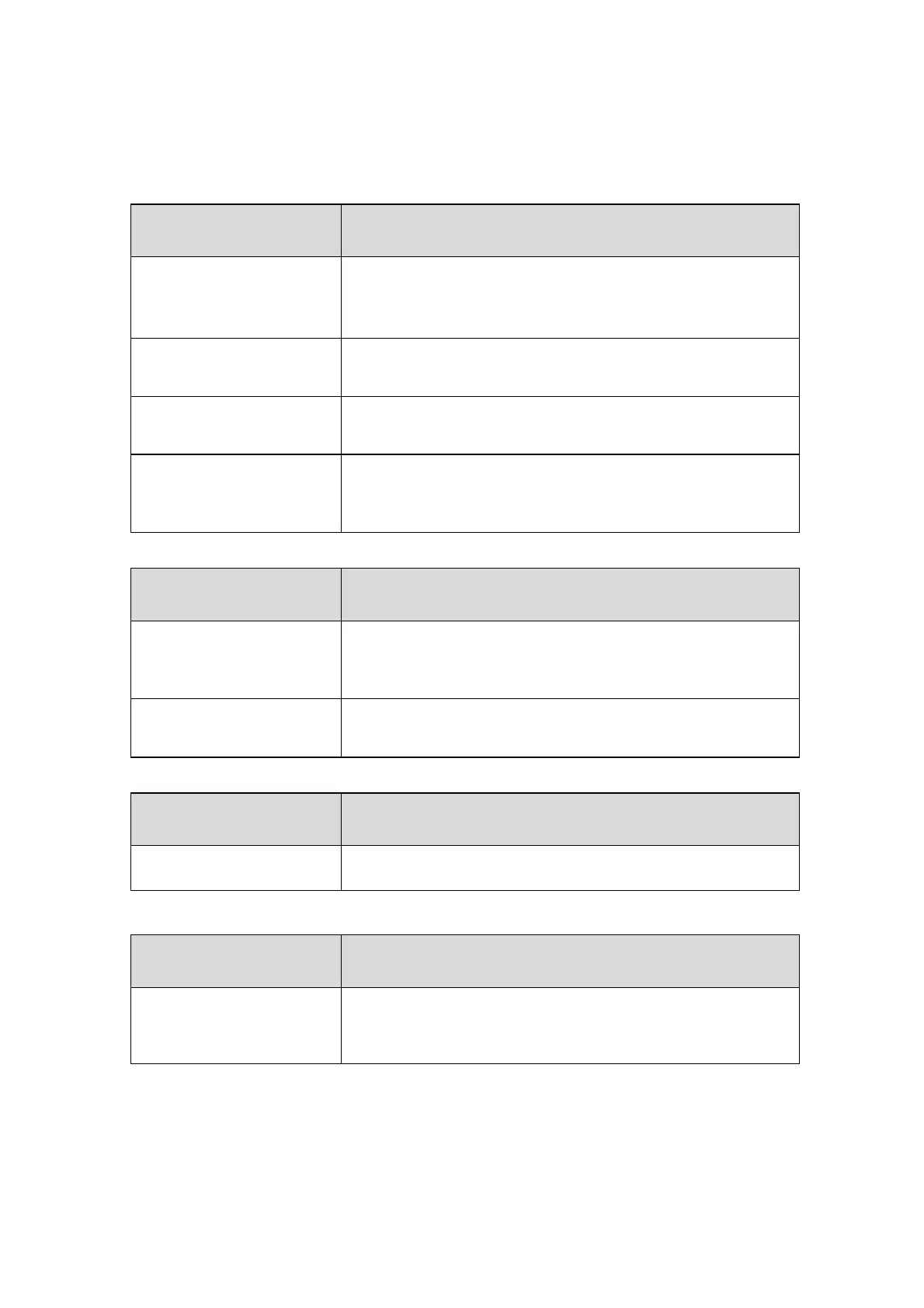

8.18.2 Peak distortion or tailing

Possible causes

Solutions

Method parameters Check all the method parameters, in particular the sample speed, the pull

up strokes (see paragraph 5.2.2.4), the injection speed and the post in-

jection dwell (see paragraph 5.2.2.5).

Needle penetration speed in GC

injector

Check the injection parameters (see paragraph 5.2.2.5).

GC injector liner not suitable Check the liner geometry according to the recommendations of the GC

manufacturer.

GC related parameters Any parameter like injector, oven or detector temperature can contribute

to bad peak shape. Check the column type and connections (square cut

connections). Check the troubleshooting guide of the GC manufacturer.

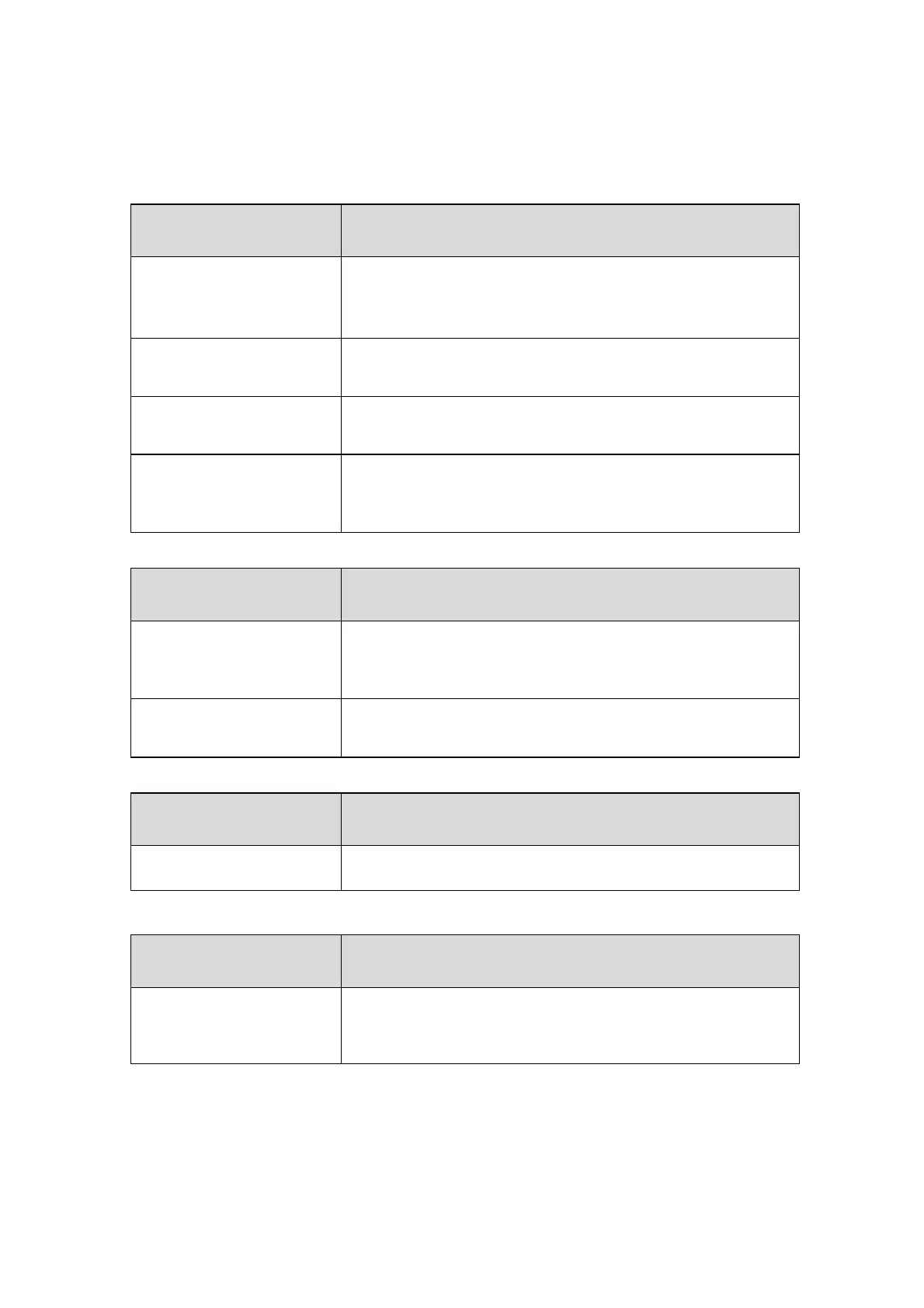

8.18.3 Carry over issue

Possible causes

Solutions

Syringe is dirty Increase the syringe purge time in the method (see paragraph 5.2.2.5).

Set the syringe temperature 10°C above the oven temperature (see

paragraph 5.2.2.3).

None or too low Syringe flush

gas pressure

Check pressure at External pressure regulator during the syringe purge.

Check gas flow at syringe needle tip.

8.18.4 Unexplained chromatographic peaks

Possible causes

Solutions

Purge gas is dirty Check purge gas for impurities.

8.18.5 Retention times not repeatable

Possible causes

Solutions

Problem in the GC system Check the GC for leaks in the inlet, including septum.

Check the liner type used.

Loading...

Loading...