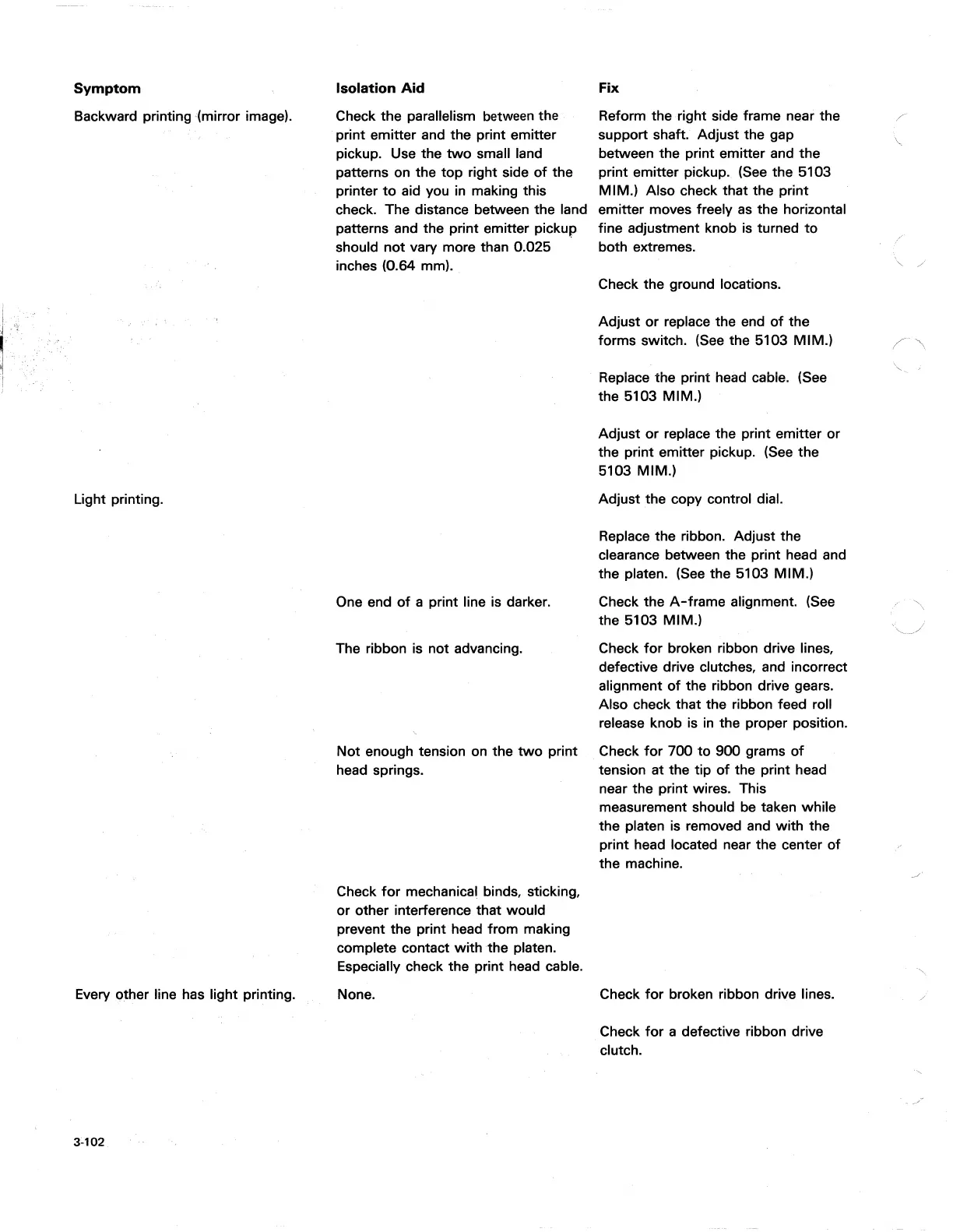

Symptom

Backward printing

'(mir~or

image).

I

I

I'

I

Light printing.

Every other line has light printing.

3~102

Isolation

Aid

Check the parallelism between the

print emitter and the print emitter

pickup. Use the

two

small land

patterns on the

top

right side

of

the

printer

to

aid you

in

making this

check. The distance between the land

patterns and the print emitter pickup

should

not

vary more than 0.025

inches (0.64 mm).

One end

of

a print line is darker.

The ribbon is not advancing.

Not enough tension on the

two

print

head springs.

Check

for

mechanical. binds, sticking,

or other interference that would

prevent the print head from making

complete contact

with

the platen.

Especially check the print head cable.

None.

Fix

Reform the right side frame near the

support shaft. Adjust the gap

between the print emitter and the

print emitter pickup. (See the 5103

MIM.) Also check that the print

emitter moves freely

as

the horizontal

fine adjustment knob is turned

to

both extremes.

Check the ground locations.

Adjust

or

replace the end

of

the

forms switch.

(See

the 5103

MIM.)

Replace the print head cable. (See

the 5103 MIM.)

Adjust

or

replace the print emitter

or

the print emitter pickup. (See the

5103 MIM.)

Adjust the copy control dial.

Replace the ribbon. Adjust the

clearance between the print head and

the platen.

(See

the 5103

MIM.)

Check the

A-frame

alignment.

(See

the 5103 MIM.)

Check

for

broken ribbon drive lines,

defective drive clutches, and incorrect

alignment

of

the ribbon drive gears.

Also check that the ribbon feed roll

release knob is

in

the proper position.

Check

for

700

to

900 grams

of

tension at the tip

of

the print head

near the print wires. This

measurement should be taken while

the platen is removed and with the

print head located near the center

of

the machine.

Check

for

broken ribbon drive lines.

Check

for

a defective ribbon drive

clutch.

/

Loading...

Loading...