c

(

(

(

c

( "

Tape

Position

Markers

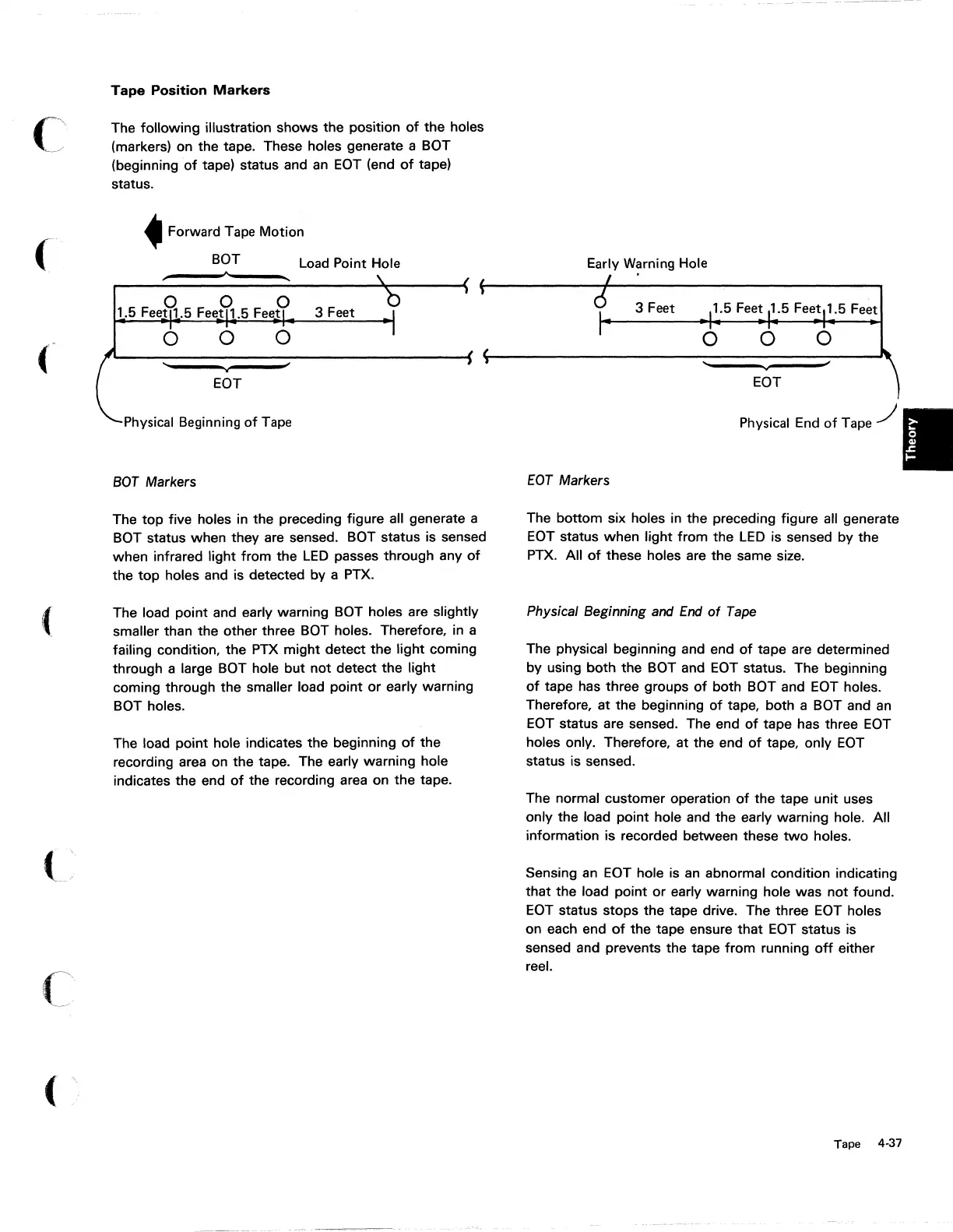

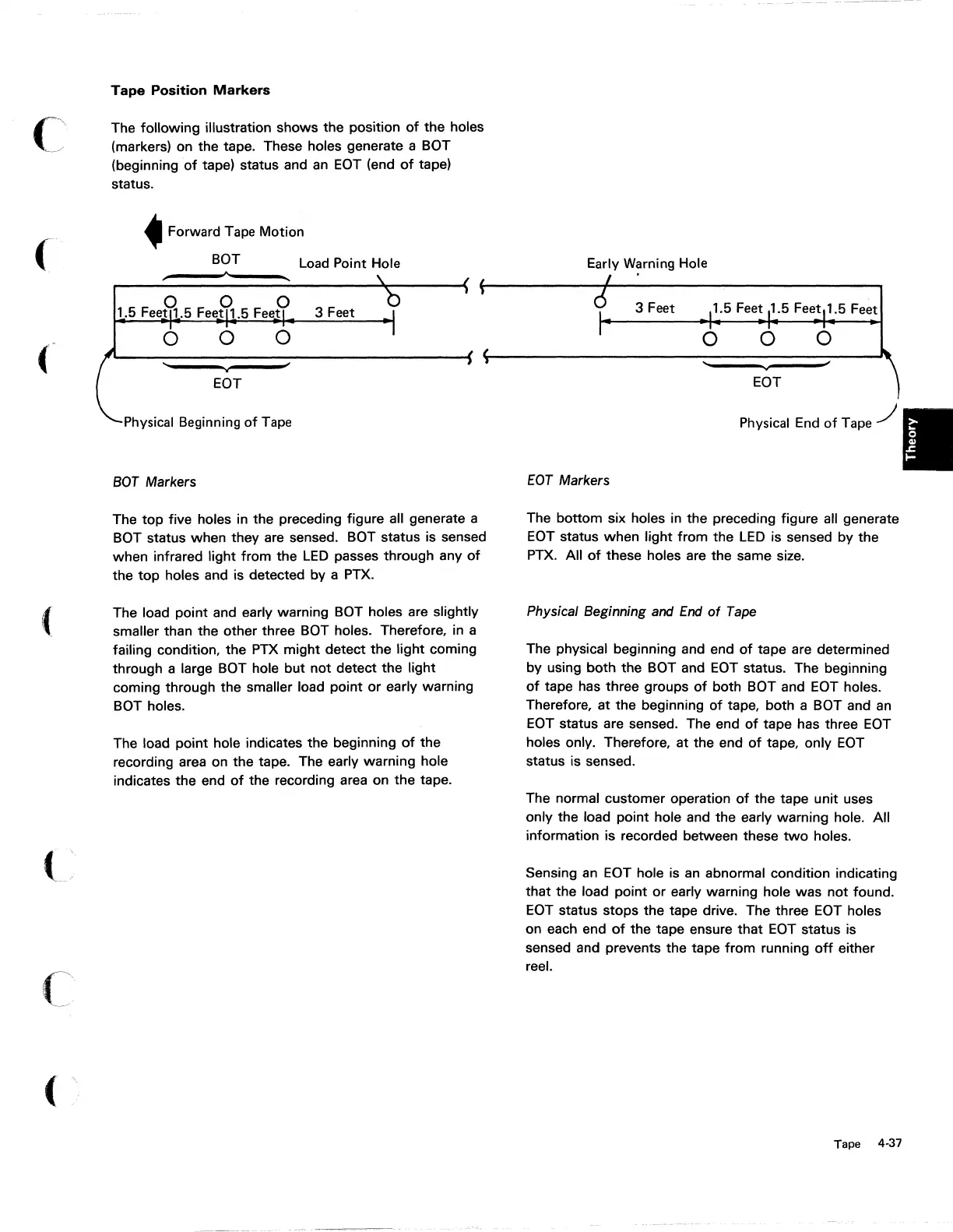

The following illustration shows the position

of

the holes

(markers) on the tape. These holes generate a BOT

(beginning

of

tape) status and

an

EOT

(end

of

tape)

status.

~

Forward Tape Motion

BOT

Load

Point Hole

3 Feet

o

EOT

Physical Beginning

of

Tape

BOT Markers

The

top

five holes in the preceding figure all generate a

BOT status when they are sensed. BOT status is sensed

when infrared light from the

LED

passes through any

of

the

top

holes and is detected by a

PTX.

The load point and early warning BOT holes are slightly

smaller than the other three BOT holes. Therefore,

in

a

failing condition, the

PTX

might detect

the

light coming

through a large BOT hole but

not

detect the light

coming through the smaller load point or early warning

BOT holes.

The load point hole indicates the beginning

of

the

recording area on the tape. The early warning hole

indicates the end

of

the recording area on the tape.

Early Warning Hole

3 Feet

o

o

o

..

EOT

Physical End

of

Tape

./

EDT

Markers

The bottom six holes

in

the preceding figure all generate

EOT

status when light from the

LED

is sensed by the

PTX.

All

of

these holes are the same size.

Physical Beginning and End

of

Tape

The physical beginning and end

of

tape are determined

by using both the BOT and

EOT

status. The beginning

of

tape has three groups

of

both BOT and

EOT

holes.

Therefore, at the beginning

of

tape, both a BOT and

an

EOT

status are sensed. The end

of

tape has three

EOT

holes only. Therefore, at the end

of

tape, only

EOT

status is sensed.

The normal customer operation

of

the tape unit uses

only the load point hole and the early warning hole. All

information is recorded between these

two

holes.

Sensing

an

EOT

hole is

an

abnormal condition indicating

that the load point or early warning hole was

not

found.

EOT

status stops the tape drive. The three

EOT

holes

on each end

of

the tape ensure that

EOT

status is

sensed and prevents the tape

from

running

off

either

reel.

Tape 4-37

Loading...

Loading...