10 Fuel extractor, type S

10.6 Installing the head piece with drop shaft

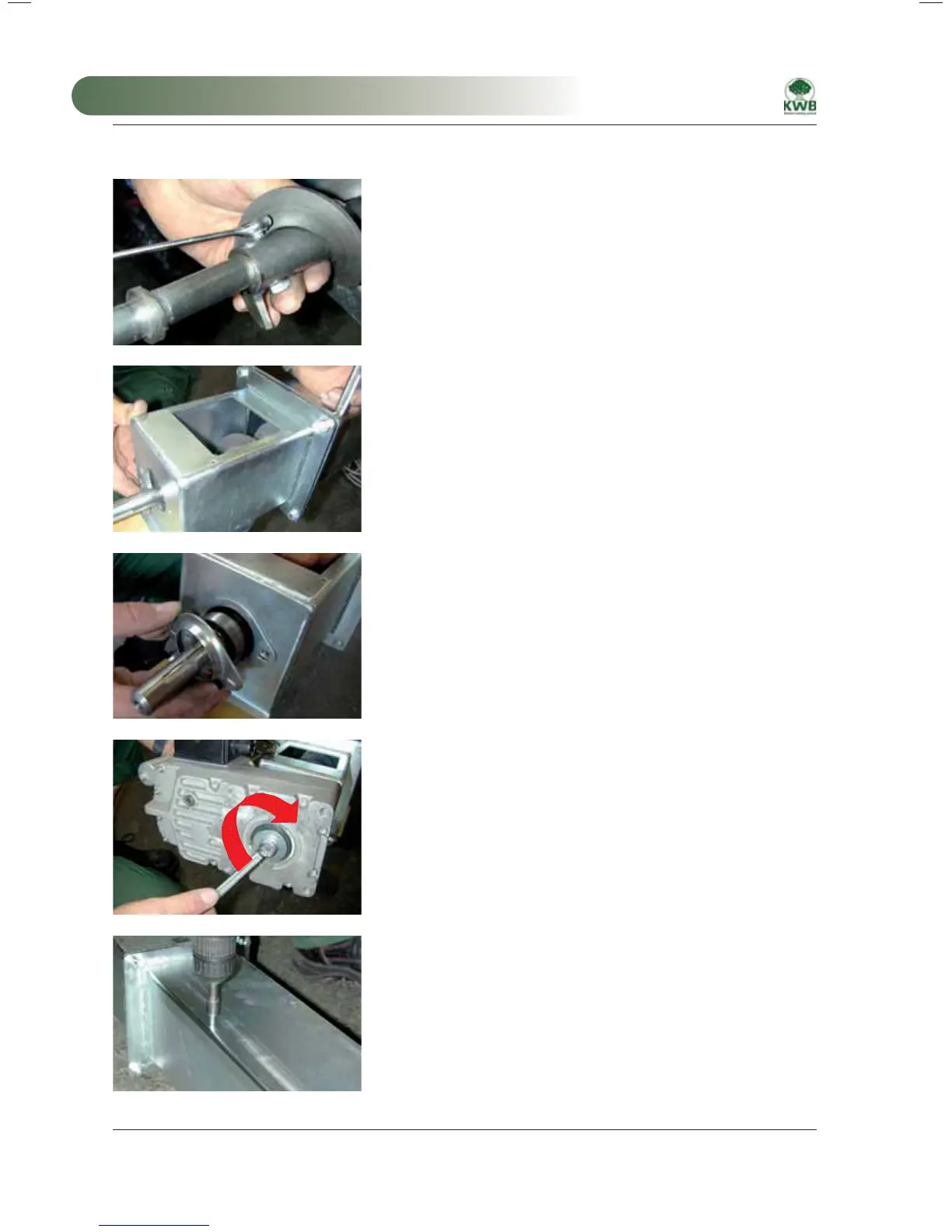

18.) Install the motor shaft

Connect the motor shaft to the conveyor worm using connecting bolts.

Tighten the bolted connection.

Install the motor shaft

19.) Fit the drop shaft

Dismount the drop shaft cover. Now fit on the drop shaft by sliding the

motor shaft through the round opening on the facing side.

Bolt the drop shaft onto the worm trough and tighten the connection.

Attach the drop shaft

20.) Install the flange bearing

Mount the bearing on the motor shaft.

In this process ensure that the feather key has been removed from the

motor shaft, if this is not the case the bearing cannot be pushed on.

Manually lift the motor shaft so that you can align the bearing. Bolt the

bearing housing tightly with the two bolts and re-insert the feather key.

To do this use a rubber mallet to avoid damage.

Install the flange bearing

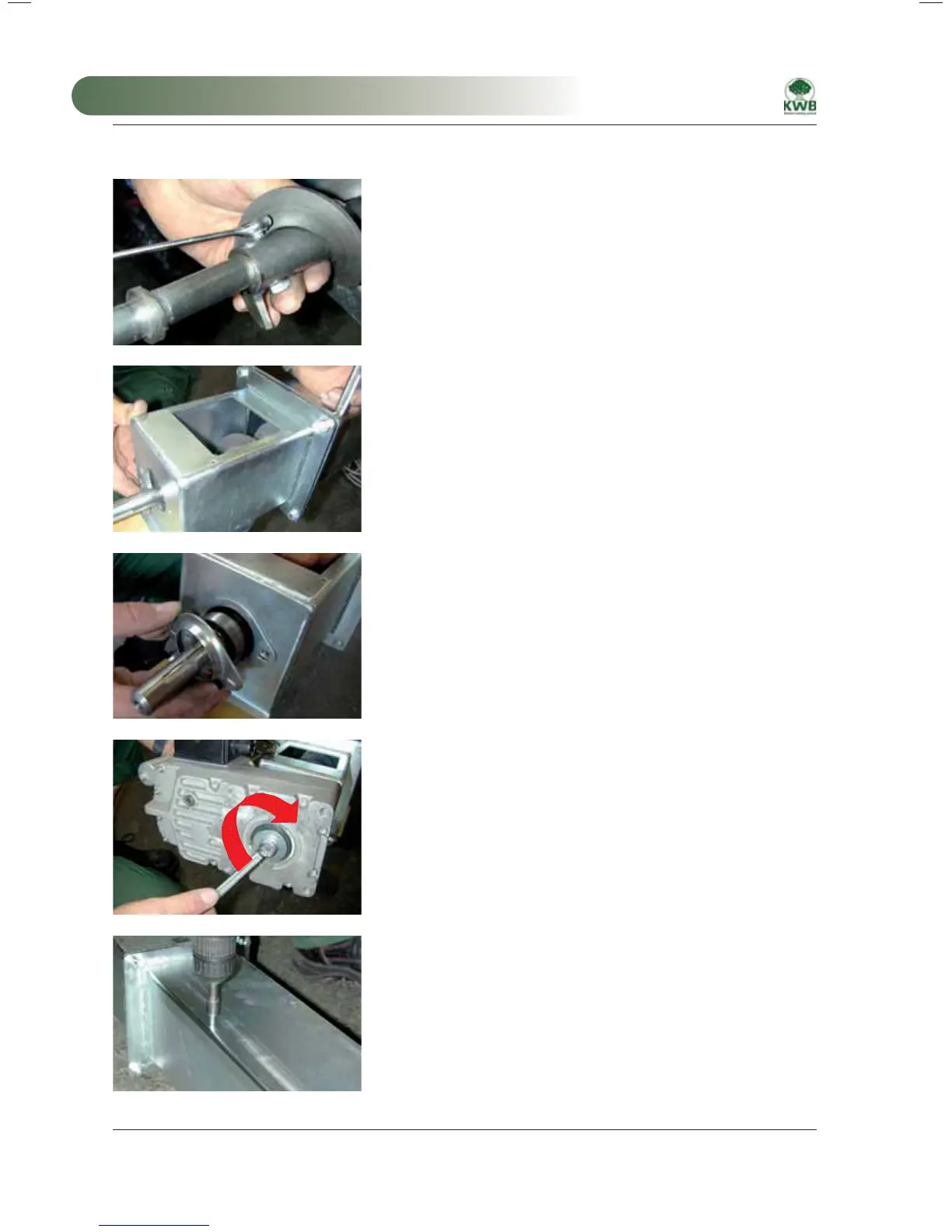

21.) Install the drive motor

Slide the drive motor onto the motor shaft. Bolt the end of the motor

shaft with the large shim and tighten this connection.

The direction of motor rotation is right-hand rotation, i.e. clockwise

rotation.

Set up the drive motor

22.) Seal the troughs

Ensure that there are no foreign objects (tools, shim material, etc.) that

have been forgotten in the fuel extractor.

Close all open covers.

Close the cover of the elbow piece last.

Close the trough covers

MA-Easyfire 10.2008_EN.indd 106MA-Easyfire 10.2008_EN.indd 106 30.03.2009 13:30:50 Uhr30.03.2009 13:30:50 Uhr

Loading...

Loading...