9 Fabric tank

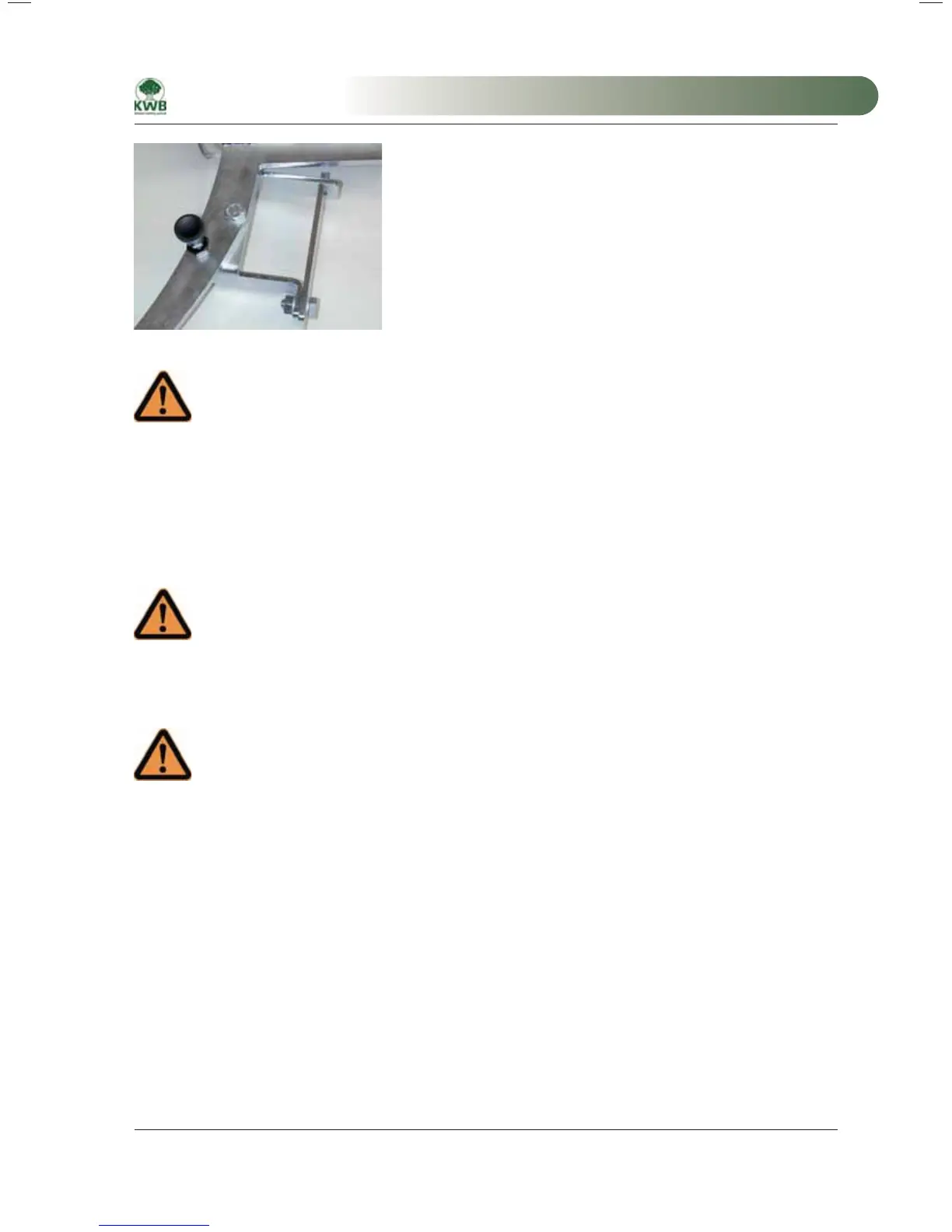

8.) Adjustment possibility, blow-in nozzle

Use the lock bolt to change the angle of incline of the fill pipe.

When filling the lock bolt remains in the arrest opening provided for this

purpose, so that there is angle of incline of the fill tube of approximately

15°.

If the fabric tank is filled the lock bolt is released and the fill tube is

swung upward to support the complete emptying of the fill hose.

The fill tube can remain in this position because the fill tube automatically

engages in the arrest opening when pellets are removed.

9 Adjustment possibility, blow-in nozzle

In special cases, such as insufficient room height, overhead lines, etc. the nozzle can also be

set horizontally. In this process you must strictly ensure that the M10 x 30 bolt is tightened

with a self-locking M10 nut.

9.12 Installing the fill system

Use the supplied clamp to install the A-Storz fill coupling on the fill tube. Naturally the fill line can be extended.

Elbow, straight pipes, and connecting clamps are available for this. Contact one of our KWB sales partners in this

regard. However ensure that the fill line is only as long as necessary and that no unnecessary bends are installed.

When permanently installing a fill line, e.g. through an exterior wall, a flexible adapter

with flared flanges on both sides must be attached to the blow-in nozzles. The holder

is fitted with an earth connection.

All parts of the fill system must be connected together so that they are conductive

and earthed!

9.13 Final inspection

Ensure that ALL components and connections are correctly installed!

To conclude, ensure that the conveyor system is free of foreign objects!

MA-Easyfire 10.2008_EN.indd 95MA-Easyfire 10.2008_EN.indd 95 30.03.2009 13:30:18 Uhr30.03.2009 13:30:18 Uhr

Loading...

Loading...