11 Fuel extractor, type S with fabric tank

11.2 Installing the inclined worm extraction system

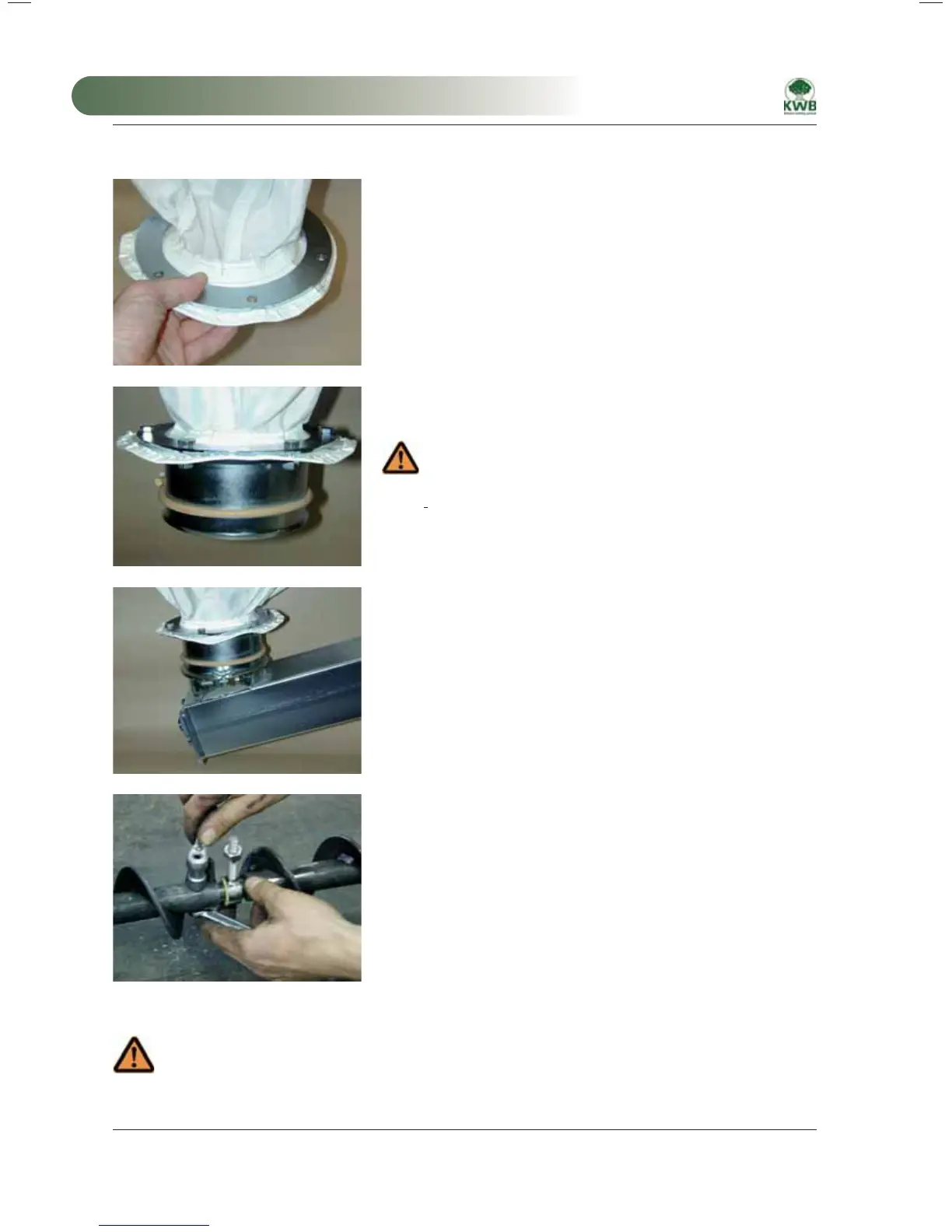

1.) Install the flange plate

Dismount the flange plate from the pre-installed gate valve. Fit the

flange over the sown-on flange of the fabric tank.

Thread on the flange plate

Bolt the flange plate, the sewn-on flange of the fabric tank and the gate

valve together so that they are permanently connected.

Insert the screws through the flange ring from ABOVE!

This prevents the tank fabric from being damaged by the protruding

thread

.

Install the gate valve

2.) Connect the inclined worm

Bring the worm trough into the storage room with previously inserted

conveyor worm.

Mount the flange bearing and unscrew the worm screw from the inner

ring of the flange bearing.

Connect the gate valve to the inclined worm. To do this use the

connecting clamp and tighten it.

If you require a worm extension go to step 3, if not continue with

step 8.

Connect the worm

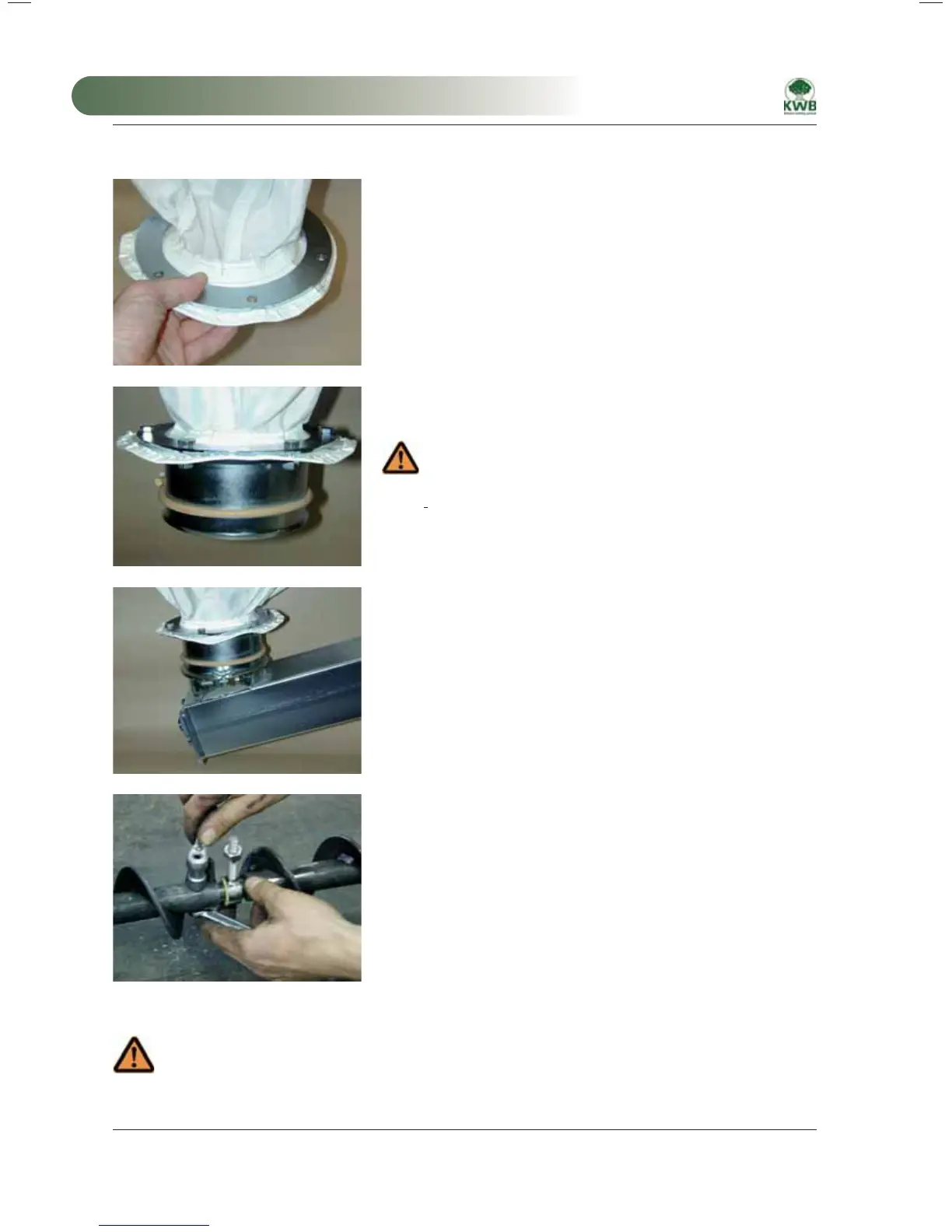

3.) Extension of the inclined worm

To extend the conveyor system various possibilities are available.

Technical data sheet MDB-USP MBK006

If an intermediate bearing is not required continue with step 6.

If an intermediate bearing is required slide the intermediate bearing onto

the extension worm and guide the connecting bolt into the hollow shaft

as shown. The two worm ends must be twisted in such a manner that

they are approximately 180° relative to each other and the cross bore is

flush. Insert the connecting bolt and tighten the screw connection.

Worm extension with intermediate bearing

The free shaft end must be supported at axis height until the intermediate bearing

is fastened in the trough. Short extension worms do not require support.

MA-Easyfire 10.2008_EN.indd 110MA-Easyfire 10.2008_EN.indd 110 30.03.2009 13:30:54 Uhr30.03.2009 13:30:54 Uhr

Loading...

Loading...