4 Operation, specialist

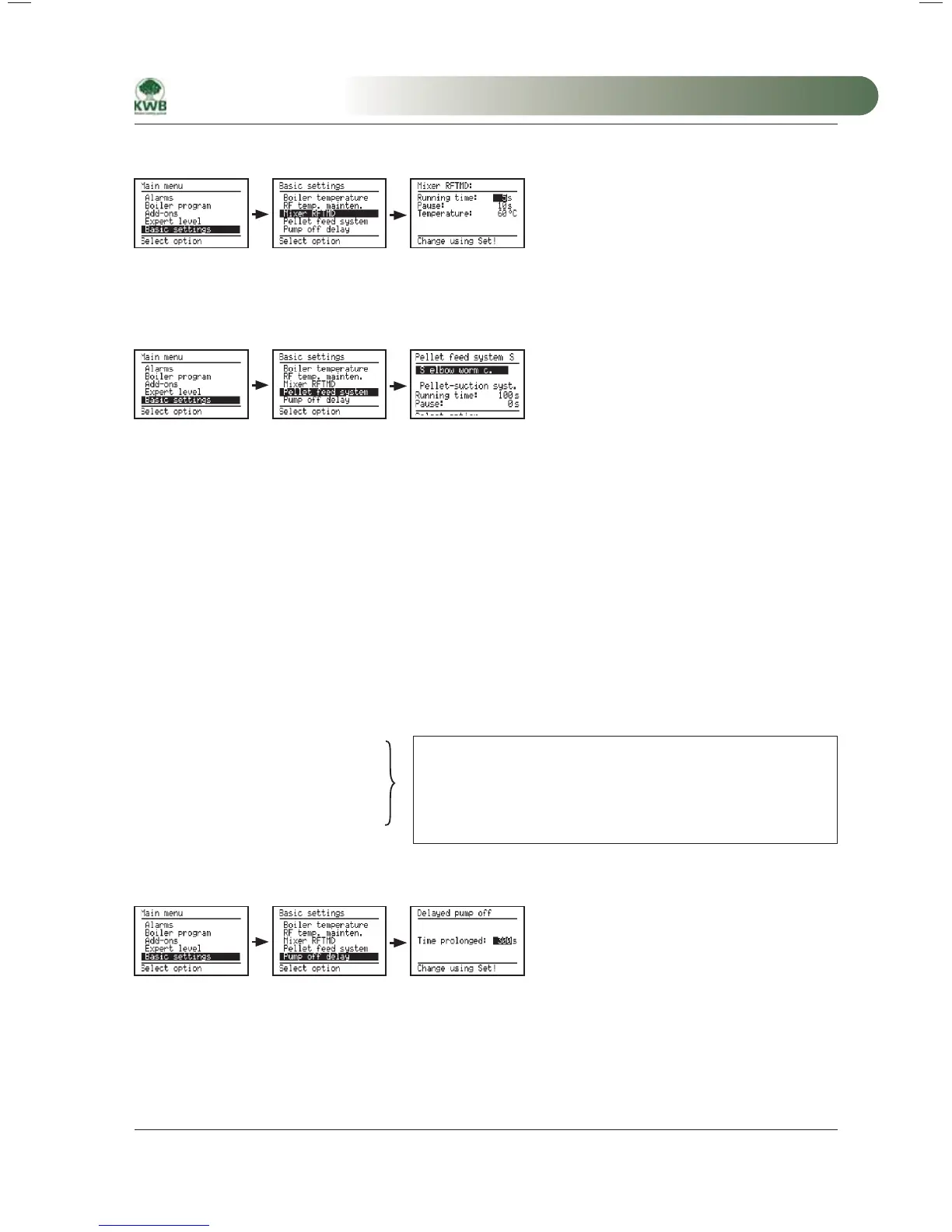

4.2.3 Mixer return flow boost

Setting of the regulating speed of the return flow boost mixer.

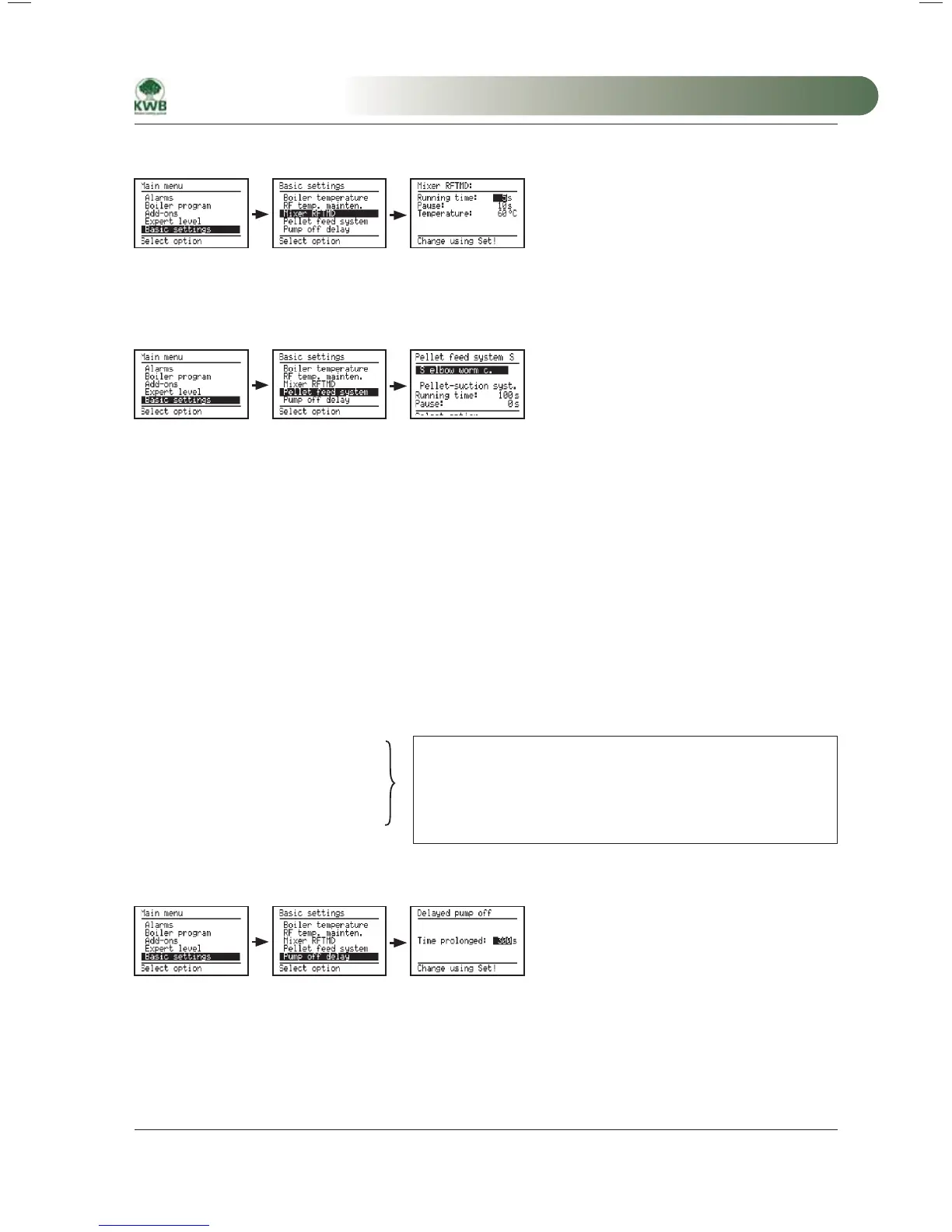

4.2.4 Pellet conveyor system

Adjustment, pellet conveyor system: The current setting is displayed by the abbreviation in the header. Settings

that are not possible due to the available hardware (for example “GS” without plug-in module 1), are corrected

automatically. (Runtime and idle time settings are ignored for types “S”, “R”, and “V”.)

General information on the suction conveyor system (GS + GL)

If the suction tank requests fuel, the vacuum fan starts up. Approximately 10 seconds later the motor of the

extractor worm starts up and moves pellets into the air current. At runtime “100 s” (factory setting) the extractor

motor runs for 100 seconds until the tank is full. If an idle time is not entered (“0 s” is factory setting), the extractor

will immediately run another 100 seconds, etc. Thus the idle time always interrupts the runtime phases. (There

are no settings for the vacuum fan – it runs independently until the tank is full and switches off approximately

10 seconds later)

S Fuel extractor with worm conveyor (Runtime and idle time settings are ignored)

R Fuel extractor with stirrer (Runtime and idle time settings are ignored)

V

Storage container system (Runtime and idle time settings are ignored)

GL

GS

Suction conveyor unit with

suction lance

Suction conveyor unit with

worm

Use idle time and runtime to control the intervals and duration

in which no pellets are transported to the conveyor hose.

We recommend “runtime 10 s” and “idle time 3 s” for

significant fine content, long conveyor distances,

significant height differential

high quantities of pellets in the conveyor hose (buried tank)

4.2.5 Pump afterrun

After switching off the boiler the boiler circuit pump and the last consumer pump will still run for another 300 seconds

to prevent heat accumulation in the boiler due to the residual heat of the fuel bed. If in spite of this measure, problems

occur due to the boiler overheating, then the afterrun time can be increased.

For troubleshooting it may be helpful to briefly set the afterrun time to 0. With this measure you can immediately

tell whether the observed aggregate actually switches off at the control system’s command.

MA-Easyfire 10.2008_EN.indd 51MA-Easyfire 10.2008_EN.indd 51 30.03.2009 13:30:07 Uhr30.03.2009 13:30:07 Uhr

Loading...

Loading...