Page 158 IM Easyfire 10/2008 © KWB – Kraft und Wärme aus Biomasse GmbH

18.1 Dimension sheets

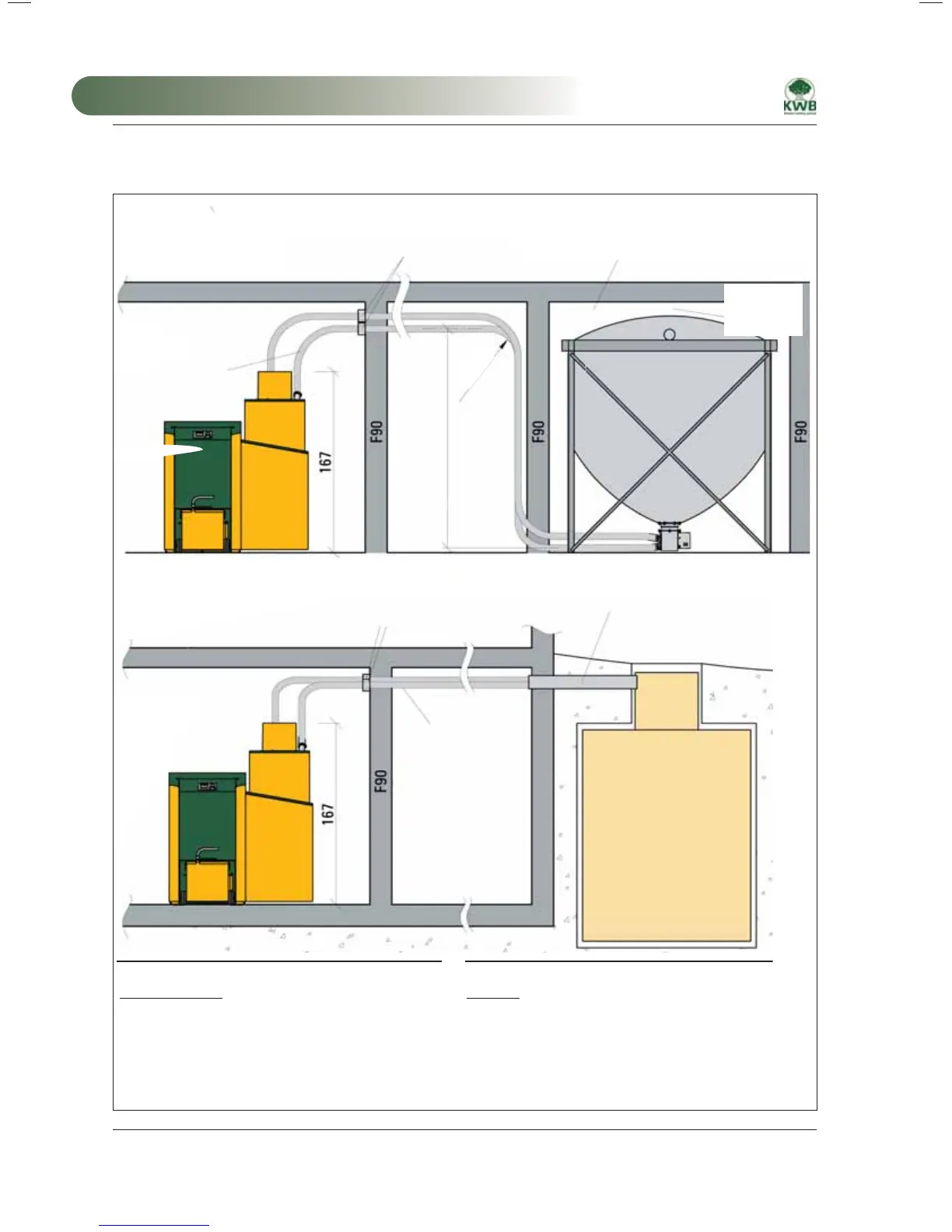

Installation example, KWB Easyfire GL

with suction conveyor unit and lance

TDB-EBB-USP-Einbaubsb. 7_B sheet 7/11

Buried Tank

Protective pipe HT pipe

at least ; 15 cm

Ceiling opening ; 70 mm

Fire-safety collar

Solid ceiling F90

fabric tank

nk

Pellet transport hose

max. length 25 m

lift without step 3 m

st after 3 m height difference 1 m route horizontally

or hose bend radii at least 30 cm.

Ceiling opening ; 70 mm

Fire-safety collar

ventilation with at least 400 cm2 must be provided.

Solid ceiling F90 Solid ceiling F90

fabric tank

system

Pellet transport hose

max. length 25 m

Min. 30

without step max. 300

Boiler

Room

Pellet Storage Room

Outline

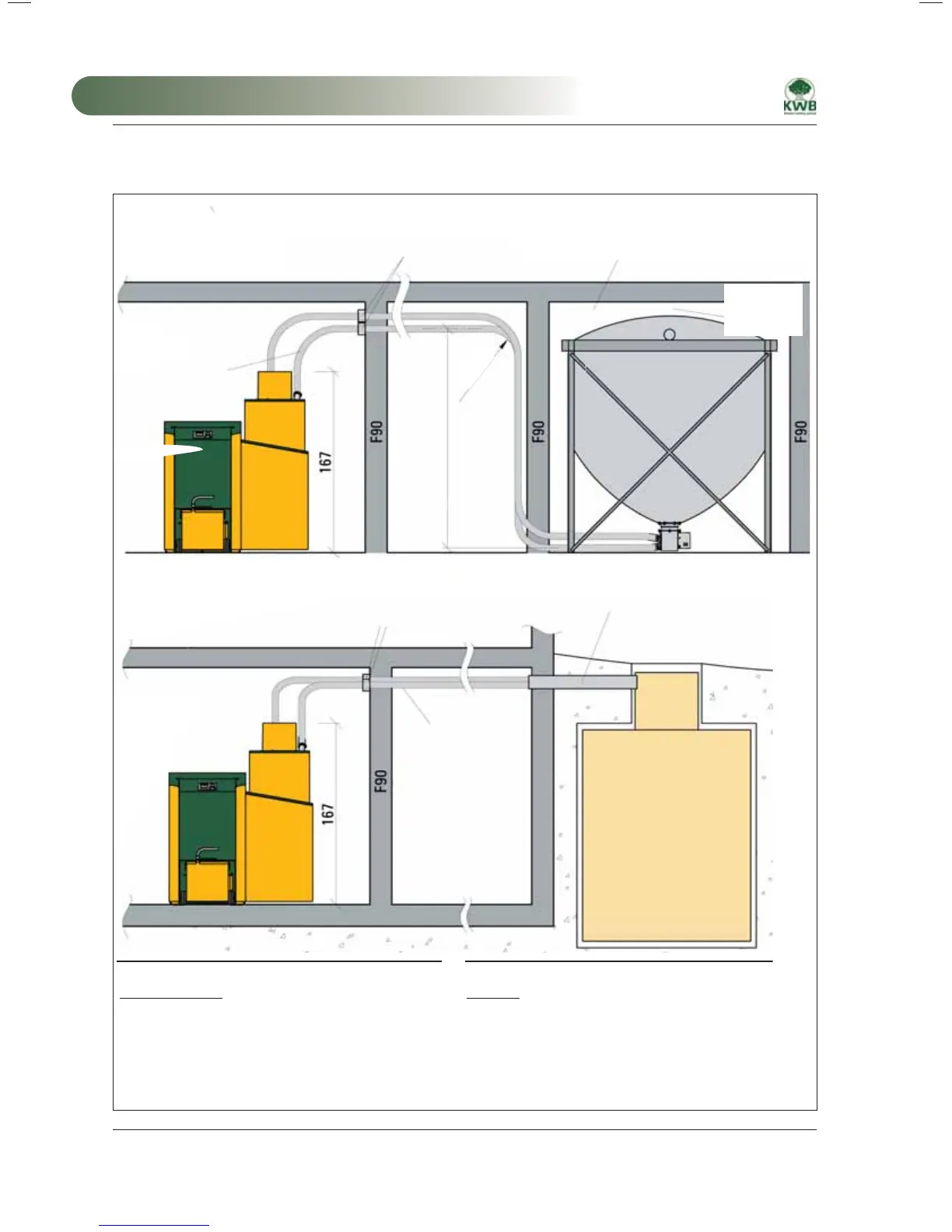

USP GL with fabric tank

and suction system

If the fabric tank will be set up in a separate room,

ventilation with at least 400 cm2 must be provided.

No sharp

objects above

he fabric tank

Hose installation (valid for all versions of the suction conveyor):

Back-up prevention:

• Max. delivery head

• At the latest after a 3 mm height differential route 1 m

horizontal

• Max. total delivery head 5 m

• Max. length of the transport hose 25 m

Fastening:

• Max. distance between holders 80 cm

• the hose should not sag between holders

• Do not mechanically stress the conveyor hose

(e.g. twist, crush, etc.

• Do not install the conveyor hose near hot surfaces

• All conveyor hose bend radii at least 30 cm

MA-Easyfire 10.2008_EN.indd 158MA-Easyfire 10.2008_EN.indd 158 30.03.2009 13:31:53 Uhr30.03.2009 13:31:53 Uhr

Loading...

Loading...