Doc #: L-2600-1023 Page 42 Rev. 02

channel to “Yes”. In the example of Figure 30, channels 2 and 4 set to automatically bypass in setup

mode.

3.3.6.4 Channel Bypass

Each individual channel can be bypassed. When a channel is bypassed, it no longer monitors its input

sensor. It will not send a stop signal to the press control if the input sensor fails to meet the

requirements of the selected channel type. The “Channel Bypass” column in the screen of Figure 30 is

the same as the “Bypassed” parameter that can be set in the miscellaneous settings screen (see Section

3.3.4.2 on page 39). It is repeated here for the convenience of setting all bypass parameters in one place.

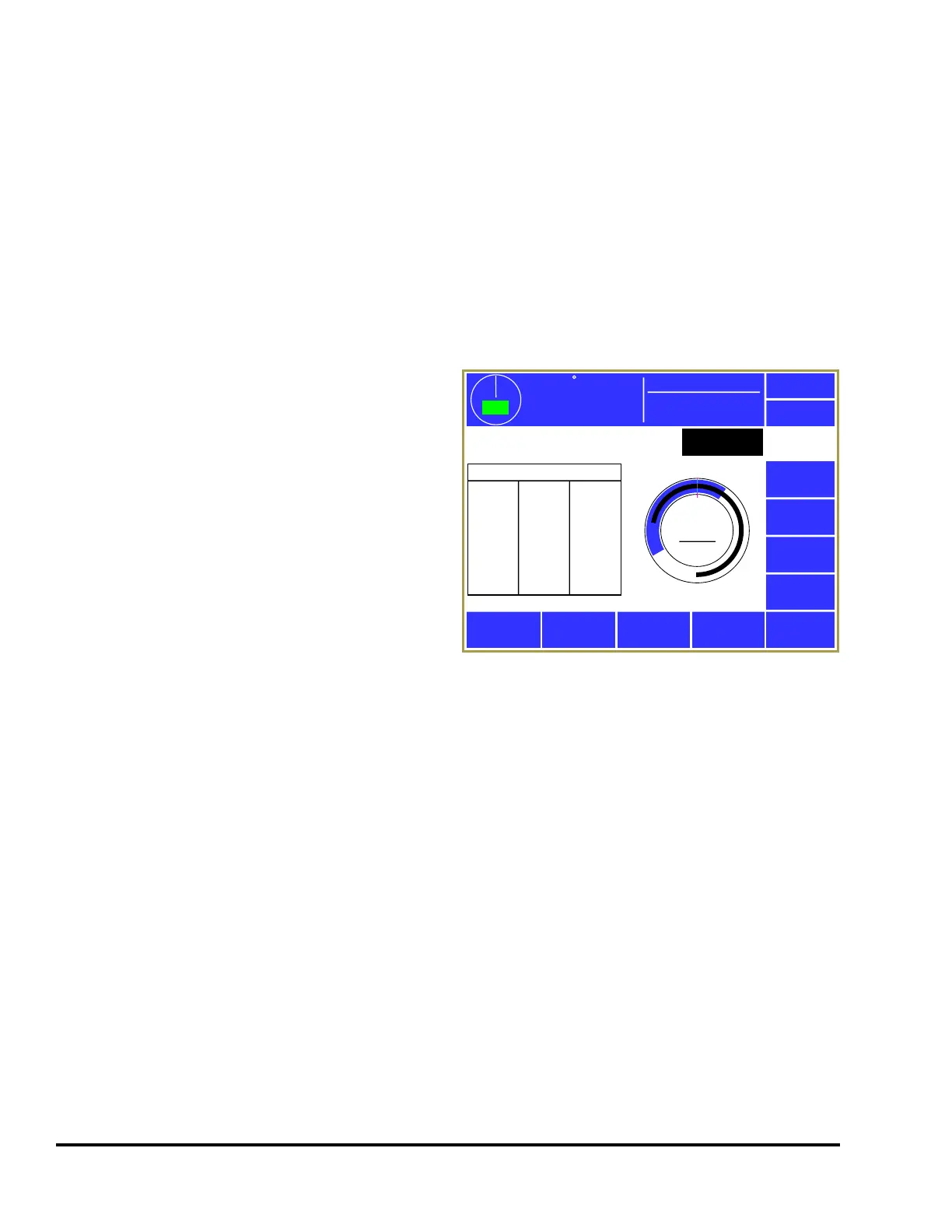

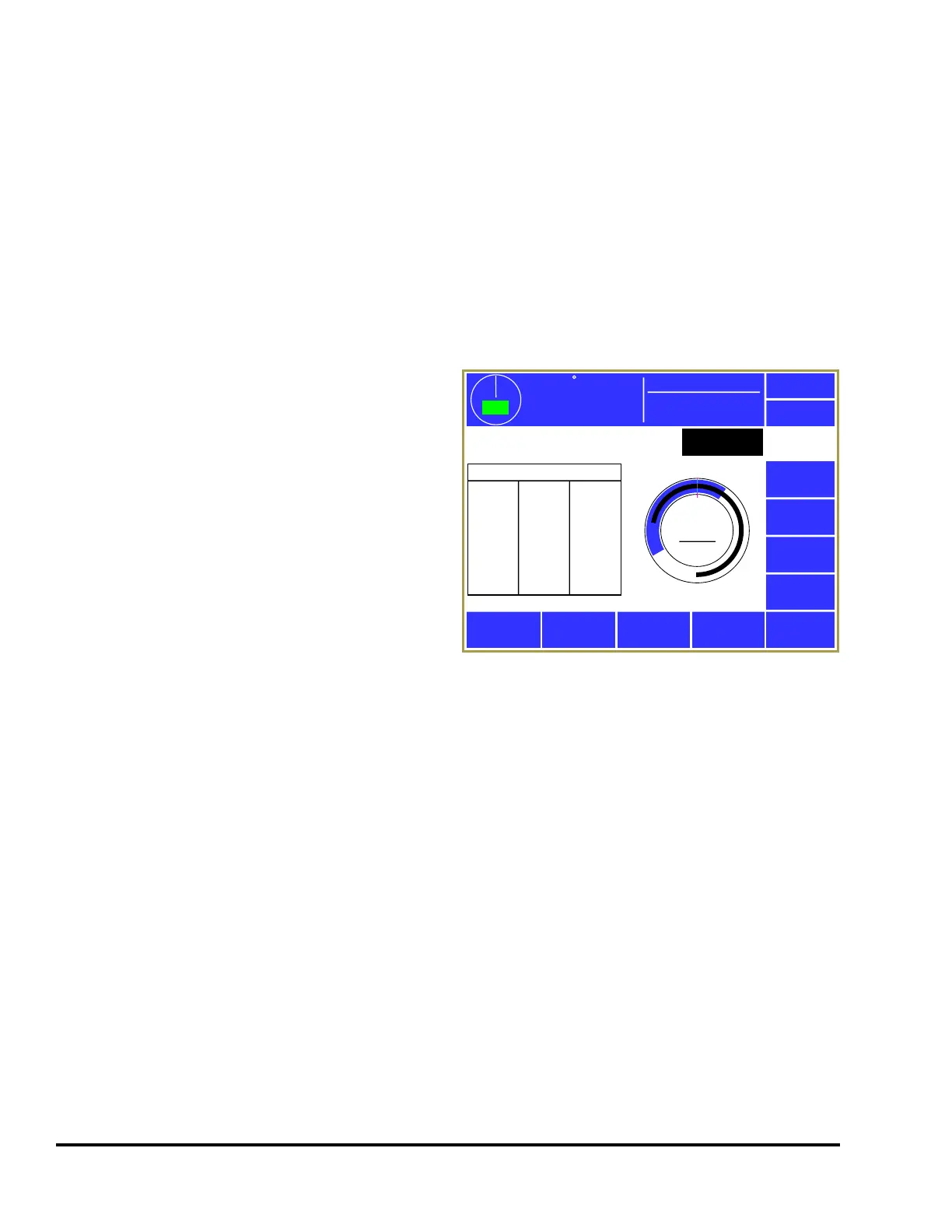

3.3.7 Die Protection Diagnose Screen

Press the Diagnose softkey in the die protection

main screen (see Figure 24 on page 33) to display

the diagnostic screen as shown in Figure 31. This

screen allows the user to diagnose the die protection

channel.

The Previous Channel and Next Channel softkeys

can be used page through the channels without

going back to the Die Protection main screen.

The blue arc in the circular angle display shows the

timing window that is set for the channel, assuming

the “Channel Type” requires one. The black arc in

the circular angle display shows the actual angles

where the sensor was “On” in the selected stroke.

This could be displayed as more than one arc if the sensor turns “On” in multiple places in the stroke.

The captured sensor angles are automatically updated every stroke. An “Angle Cursor” is displayed on

the circular display and is controlled by the Decrement Cursor and Increment Cursor softkeys. A

numeric readout of the cursor angle is shown in the center of the circle.

At the top of the screen the actual input state of the channel is displayed (“On” or “Off”). Below that is

the number of “in window” transitions that occurred the last time through the timing window (or the

current number of transitions if currently inside the window). This can be of help in diagnosing sensor

bounce or setting separation times when using 2 part detector channel types.

On the left side of the screen is a list of “On:Off” angle pairs for the currently displayed stroke. Each

entry in this list represents an event where the sensor turned on and back off. These are numeric values

that correspond to the black arc or arcs that are shown in the circular display to the right.

When this screen is entered, the default display is the last full stroke (0 to 359 degrees). This means that

if the current crank angle is at 45 degrees, the display is showing the data from the stroke before. The

Decrement Stroke and Increment Stroke softkeys are used to change the stroke that is shown on the

screen. This can range from the current stroke (0 degrees to the current angle) to as many as about 20

strokes back. The exact number of strokes back that can be viewed is dependent on the number of

transitions that have occurred per stroke. The system stores the last 64 on/off transitions.

359

TOP

Stroke Speed

0

SPM

ACC

Espanol

Exit

Die

Protection

Overlay

Strokes

Previous

Channel

Next

Channel

Increment

Cursor

Decrement

Cursor

Increment

Stroke

Decrement

Stroke

Die Prot.

Channel 3

0

270

180

90

Angle

Cursor

0°

Input:

In Window Transitions:

Stroke Shown: Last Full Stroke

Capture Angles (On:Off)

279:181

Off

1

Mode:

Production

Figure 31: Die Protection Diagnose Screen

Loading...

Loading...