Doc #: L-2600-1023 Page 80 Rev. 02

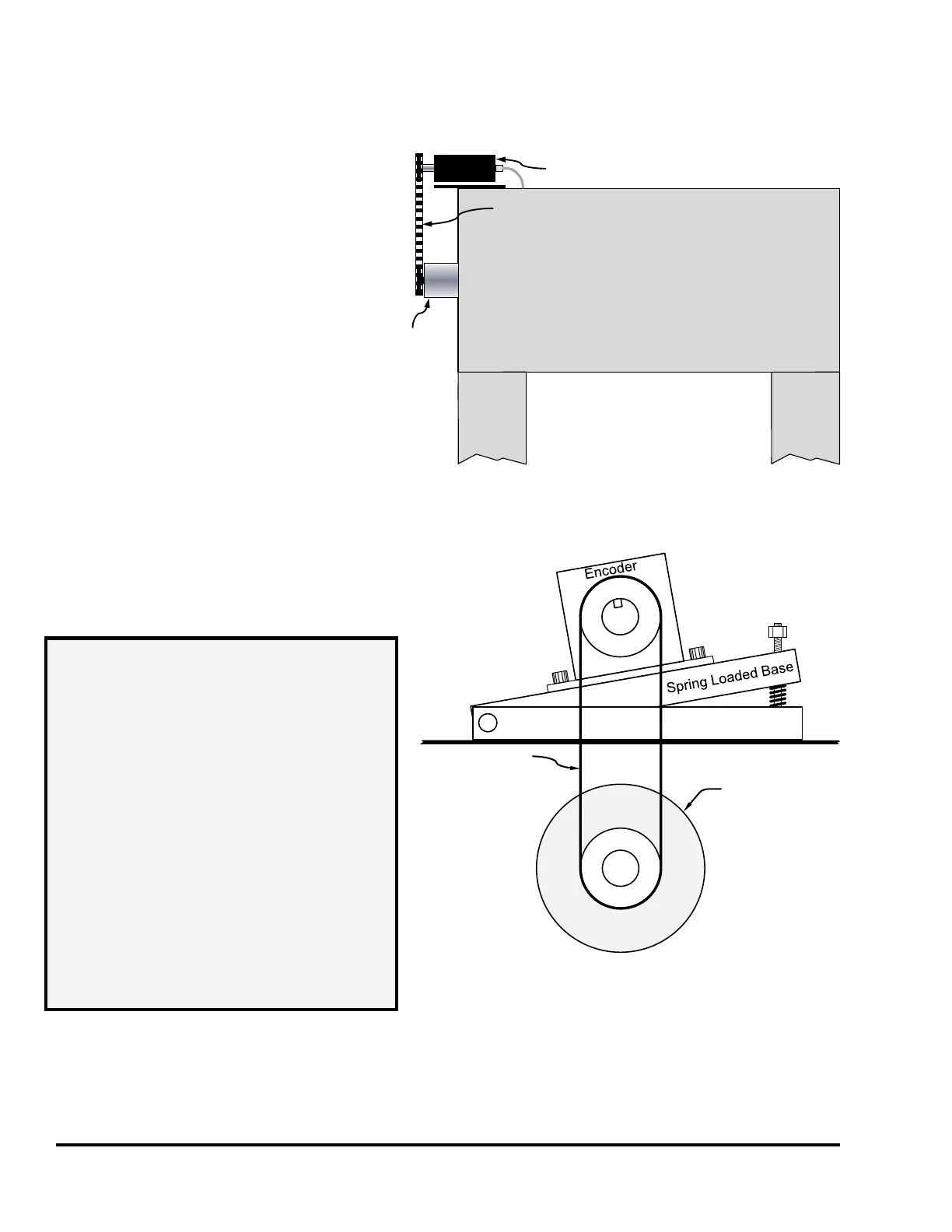

7.3 Mounting the Encoder

The System 2600 requires a Link

5100-11 encoder to get angle

information from the crankshaft or

eccentric.

The encoder may be direct driven by a

coupling off the center of the shaft or

driven by a chain or timing belt as

shown in Figure 70.

Chain and sprockets may have been

purchased from Link Systems. If so,

the sprockets will be 35B28 (28 teeth)

and chain will be size 35 roller chain.

Link suggests that, if the customer

provides chain and sprocket, the same

type be used. The electronic offset

capability (see Section 4.3.2 on page 57) during calibration can correct mechanical misalignment.

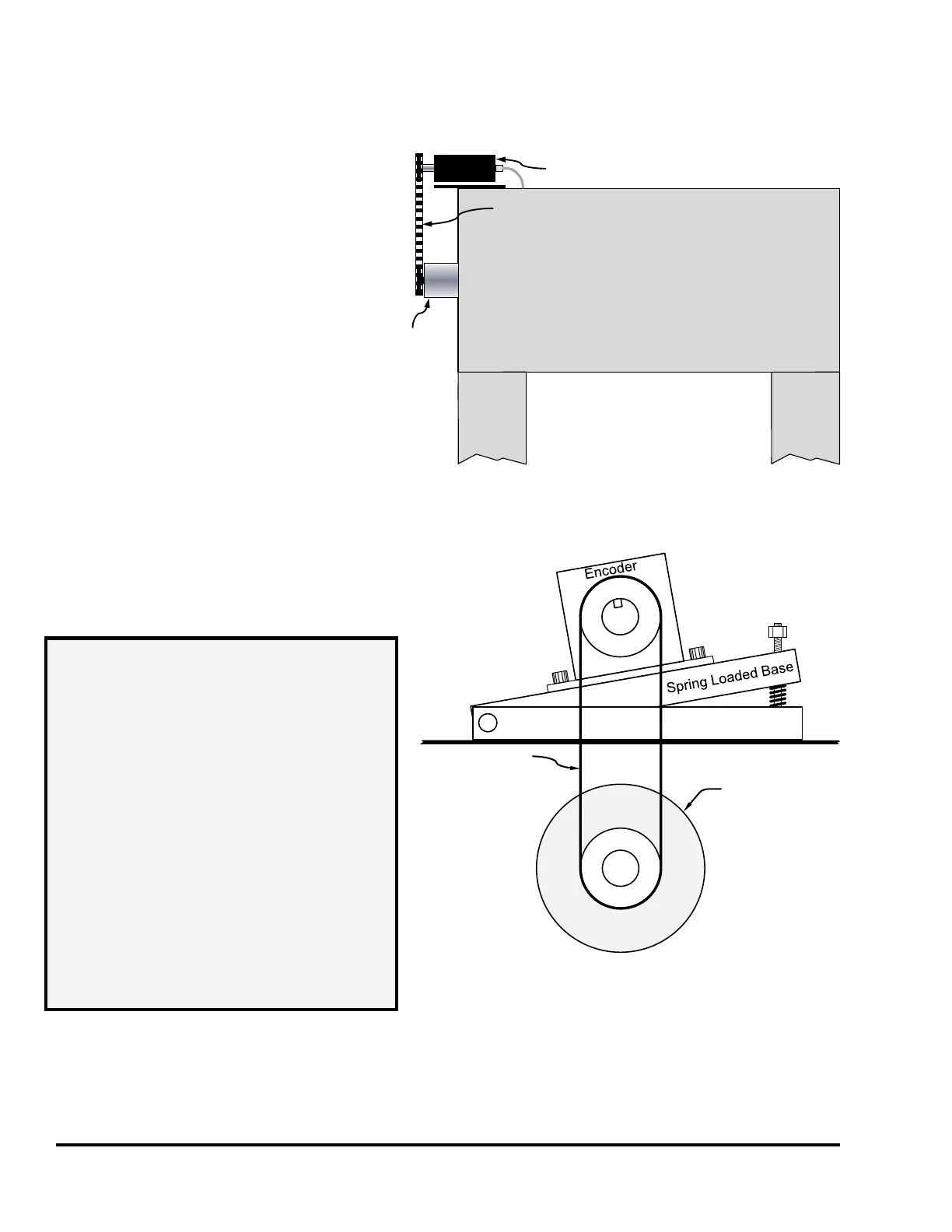

A spring-loaded mounting base (see Figure

71) will be supplied when the encoder will be

chain driven to maintain chain tension.

The 5100-11 encoder shaft is 3/4 inches in diameter with a 3/16 inch wide by 1 inch long standard

keyway. The sprocket attached to the encoder must be bored and keyed to fit. Do not install the

sprocket without a proper size key. After installing sprocket and key, the clip ring must be installed in

the groove on the end of the resolver shaft.

Press

Crown

Crank or

Eccentric

Shaft

Resolver or

Encoder

Chain or

Timing Belt

A chain guard is

necessary to meet

OSHA 1910.219

Standards

Note:

Figure 70: Resolver Mounting to Shaft

Crank or

Eccentric

Shaft

Chain

Figure 71: Encoder on Spring Base

NOTE: The encoder must be driven on

a one-to-one basis with the

press. That is, one stroke of the

press must result in exactly one

turn of the encoder. If you have

a press that only provides access

to an intermediate shaft or back

shaft for connection of the

encoder, you will have to

determine how many turns this

shaft makes for each turn of the

crank or eccentric shaft. You

must then use sprockets of

different size, chosen to provide

one turn of the encoder for one

turn of the crank or eccentric

shaft.

Loading...

Loading...