Doc #: L-2600-1023 Page 57 Rev. 02

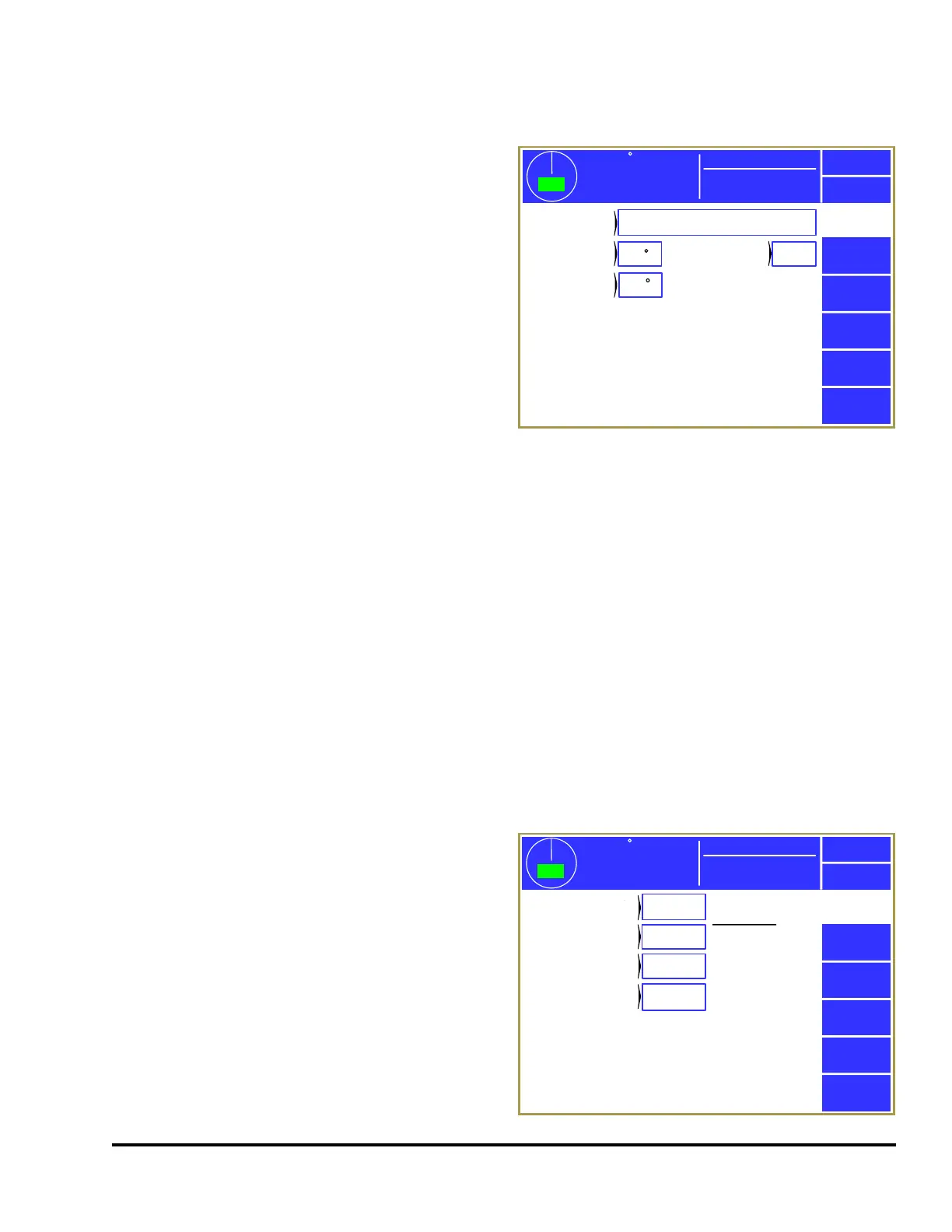

4.3 Encoder Settings Configuration Screen

Press the Encoder Settings softkey in the main

configuration screen as shown in Figure 43 to

display the screens shown in Figure 45.

4.3.1 Trigger Mode

This parameter is fixed as “Link 5100-11 Rotary

Transducer” and cannot be changed.

4.3.2 Encoder Offset

This parameter is used at installation to set the zero

position of the encoder at the top of the stroke. The

offset can be entered directly, or the press can be

positioned at the top of the stroke and Set Zero

selected or at the bottom of the stroke and Set 180 selected. These softkeys will select the proper

encoder offset value to make the current reading 0 degrees or 180 degrees respectively.

4.3.3 Encoder Reversed

This parameter allows flexibility when mounting the crankshaft transducer by allowing it to turn

counter-clockwise when the press is running in the forward direction if set to “Yes”.

4.3.4 Crankshaft Hysteresis

This parameter controls how much in the opposite direction from the initial direction of travel the

crankshaft must move before the system allows the reading to change or “go backwards”. It is used to

prevent false triggering of limit switch and die protection windows when the press is right on the edge of

a window and the reading varies due to vibration and/or chain or coupler slack. 5.0 degrees is normally

a reasonable value and this should only be changed if instructed by Link technicians.

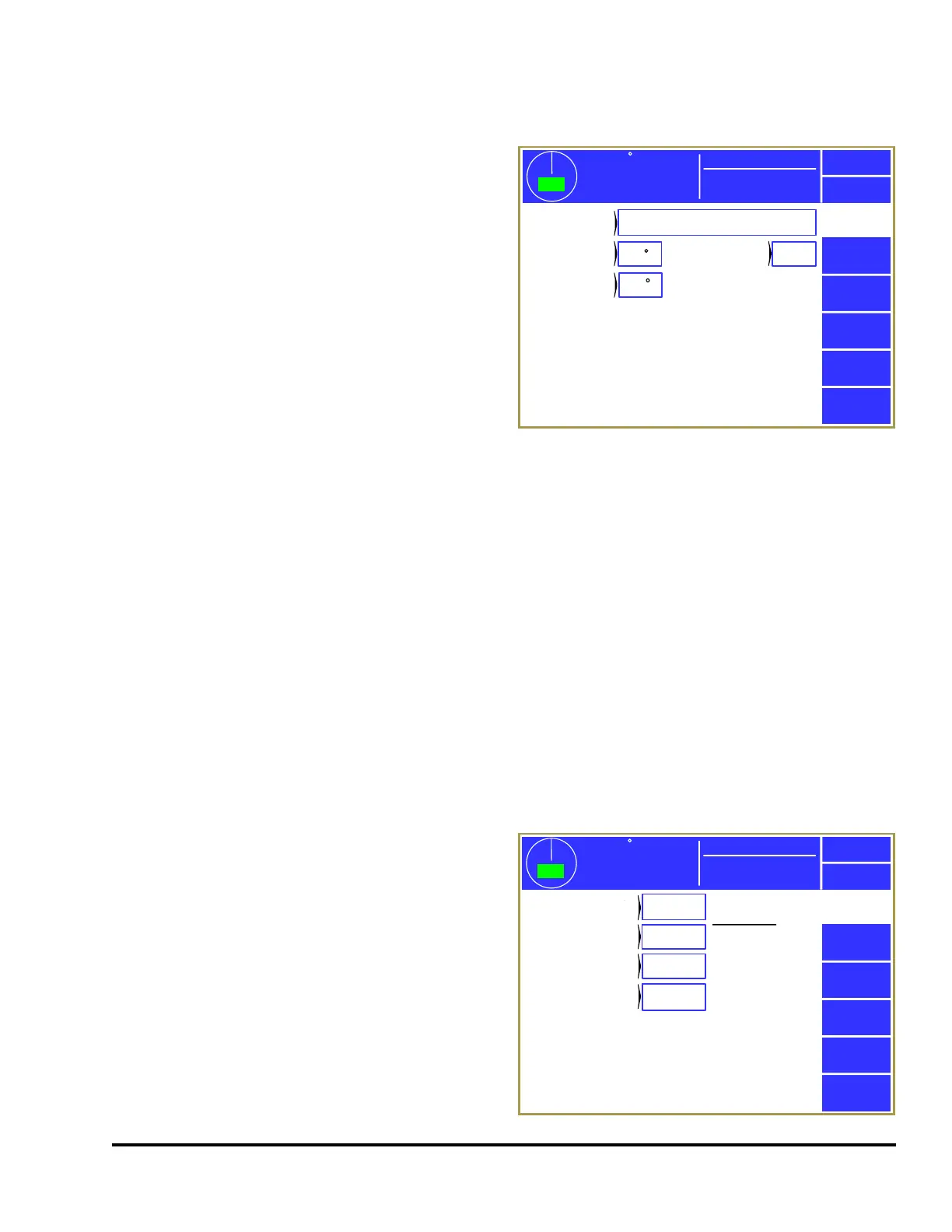

4.4 RUN (Clutch/Brake) Input Settings Configuration Screen

Press the RUN (Clutch/Brake) Input Settings

softkey in the main configuration screen as shown

in Figure 43 to display the screens shown in Figure

46.

The System 2600 can optionally use a motion

detection system to detect coupling failures that

result in the encoder not being driven by the

crankshaft. If encoder decoupling occurs, the

system cannot perform its monitoring and control

functions that depend on crankshaft angular

position. The motion detector generates an

immediate stop signal if it senses motion below the

SPM (strokes per minute) configured in the

0

Exit

359

TOP

Stroke Speed

0

SPM

ACC

Espanol

Link 5100-11 Rotary Transducer

0

5.0

Mode: Production

Die

Protection

Set Zero

Set 180

Trigger

Mode

Encoder

Offset

Crankshaft

Hysteresis

No

Encoder

Reversed

Figure 45: Encoder Settings Screen

0

Exit

359

TOP

Stroke Speed

0

SPM

ACC

Espanol

Yes

125 ms

3 SPM

50 ms

Mode: Production

Die

Protection

Use RUN

(Clutch/Brake) Input

Engagement

Time Limit

Motion

Threshold

Loss of

Motion Time

Last Actual

105 ms

Figure 46: RUN Input Settings Screen

Loading...

Loading...