Doc #: L-2600-1023 Page 27 Rev. 02

“Window Off” angle should be set to a point after the material has been fed into place. If the material is

not in position by the end of the timing window, a fault will be generated. The “Window Off” angle

must also be set so that the fault will stop the press before the die closes enough to cause damage.

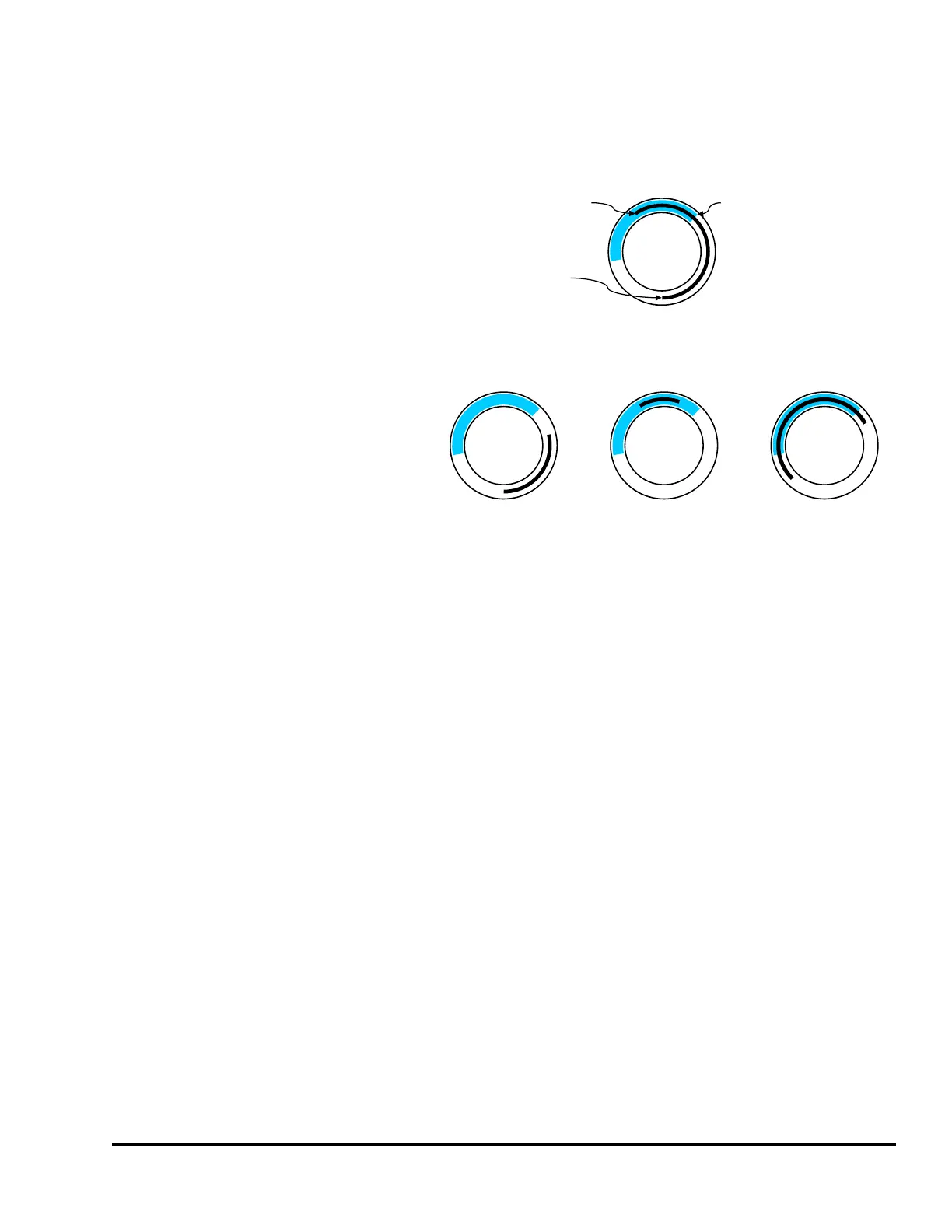

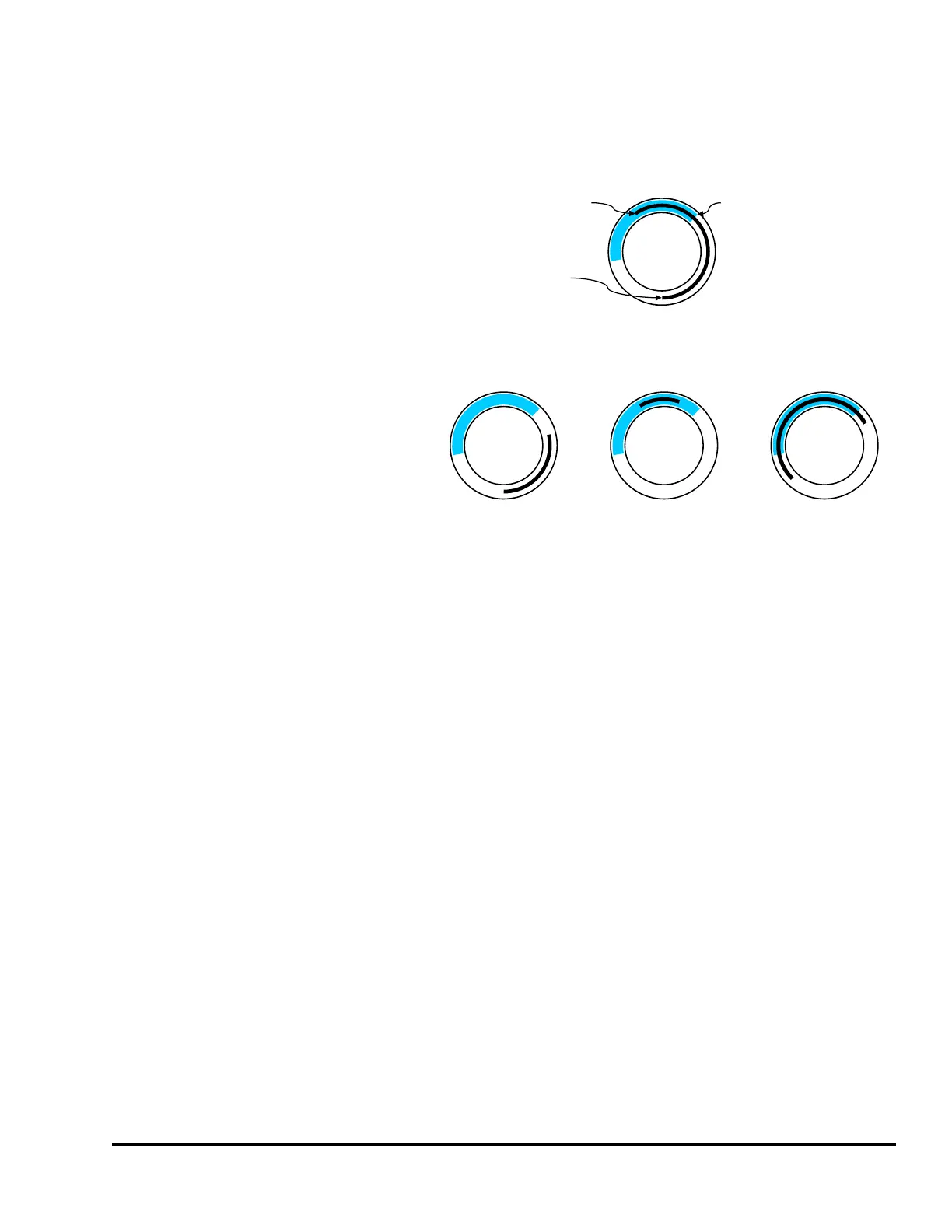

An illustration of the In Position timing

sequence is shown in upper part of

Figure 14. This figure shows that the

material was fed into place during the

timing window and that the material

was in place at the end of the timing

window.

Figure 14 also shows some

unacceptable conditions for In Position

events. There are three unacceptable

conditions shown. The left

unacceptable condition shows that the

feed was not in place at the end of the

timing window. The center

unacceptable condition shows that the

material did arrive in place during the

timing window, but was not in place at

the end of the window. As shown in

Figure 13, this condition could occur in overfeed situations. The right unacceptable condition shows that

the material was sensed as being in position before the beginning of the timing window. All of these are

fault conditions.

The “Input Type” of the sensor being used to verify material position can be “Normally Off” or

“Normally On”. The sensor will switch from its normal state when the material is in position. When a

“Normally Off” sensor is being used to sense material position; the sensor will be “Off” when the

material is not in place, and will be “On” when the material is in place. The example illustrated in

Figure 13 is an example of a “Normally Off” sensor. When a “Normally On” sensor is being used to

sense material position; the sensor will be “On” when the material is not in place, and will be “Off”

when the material is in place. An example of a “Normally On” application is detecting proper material

position by looking for a hole in the material. The sensor is “On” when there is material over the sensor.

The sensor will switch to “Off” at the proper feed position when the hole is over the sensor.

3.3.1.4 In Position Inhibit

“In Position Inhibit” operates the same as “In Position” but with the additional characteristic that when

the press is stopped inside the timing window, it will assert a stop until the sensor turns on. In other

words, it will not allow the press to start until the sensor is made. When the press is running, it operates

exactly like “In Position”. This mode is especially handy when the press is running in Single Stroke

with a long and/or slow feed progression as it prevents the next stroke until the material is in place.

Otherwise, it might be possible to “false start” and hit the end of the timing window before the material

has fed up – which will then cause a stop in the downstroke. Also see section 4.2.5 on page 56 for more

information on how inhibit behaves and the considerations for its use.

0

180

90

270

0

180

90

270

0

180

90270

0

180

90

270

Acceptable

Unacceptable

New Material Fed

Into Position

Feed Checked

Material Cut

Away By Die

Figure 14: Timing Window Examples for an “In Position” Input

Loading...

Loading...