Doc #: L-2600-1023 Page 81 Rev. 02

Another sprocket must be attached to the machine shaft. The proper size hole must be drilled and

tapped in the static center of the machine shaft. After attaching the sprocket to the shaft, an additional

hole should be drilled approximately 3/4 inch off of the static center. This hole should be drilled

through the sprocket and into the machine shaft. The sprocket should be removed and the off-center

hole in the machine shaft tapped for a 1/4 inch bolt or larger. The off-center hole in the sprocket must

provide proper clearance for the bolt. Attach the sprocket to the machine shaft with the center bolt and

the off-center bolt. When attaching the chain to the sprockets, it is not necessary for the zero position of

the encoder to be aligned with the top dead center of the machine shaft. The system allows the user to

program an offset value to make up the differences between the machine top dead center and encoder

zero.

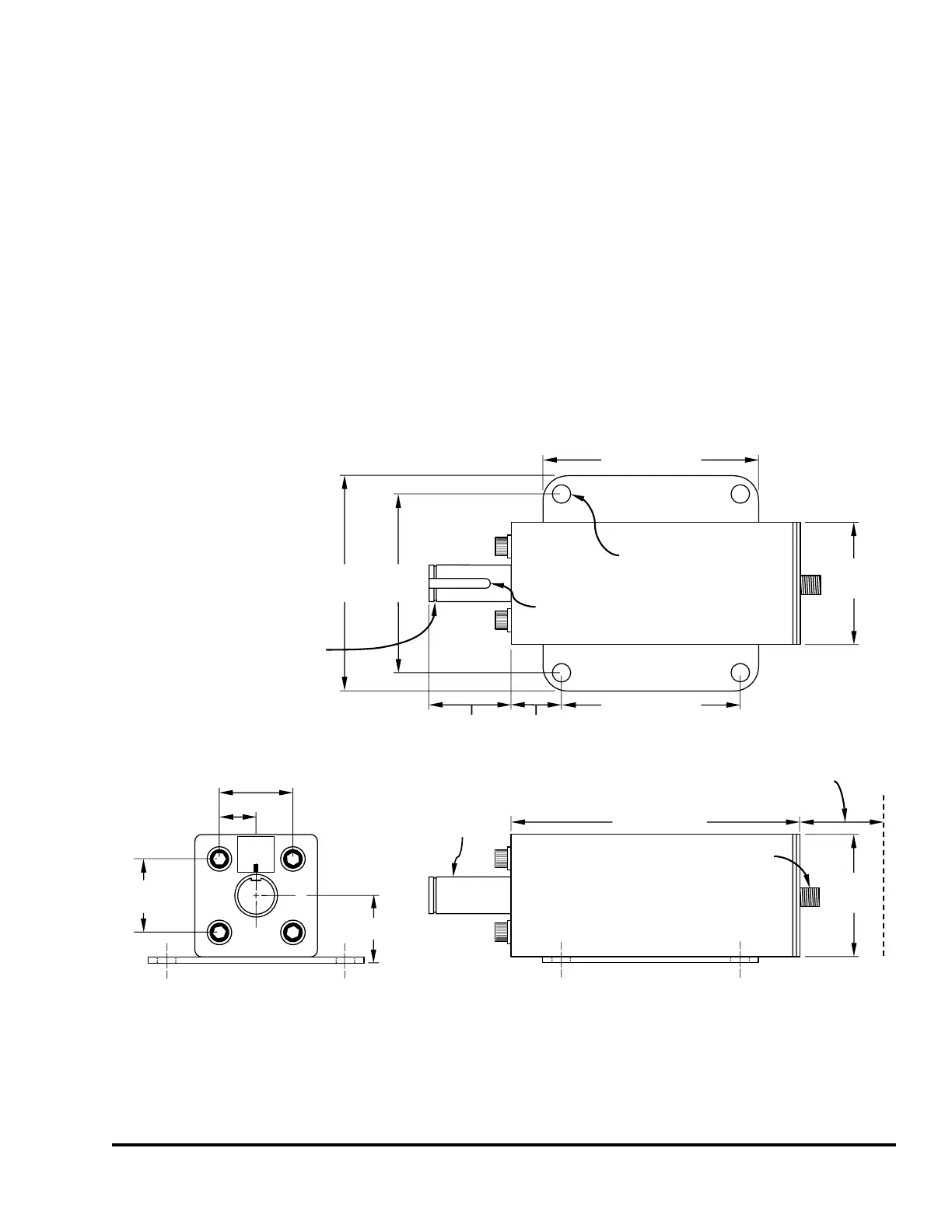

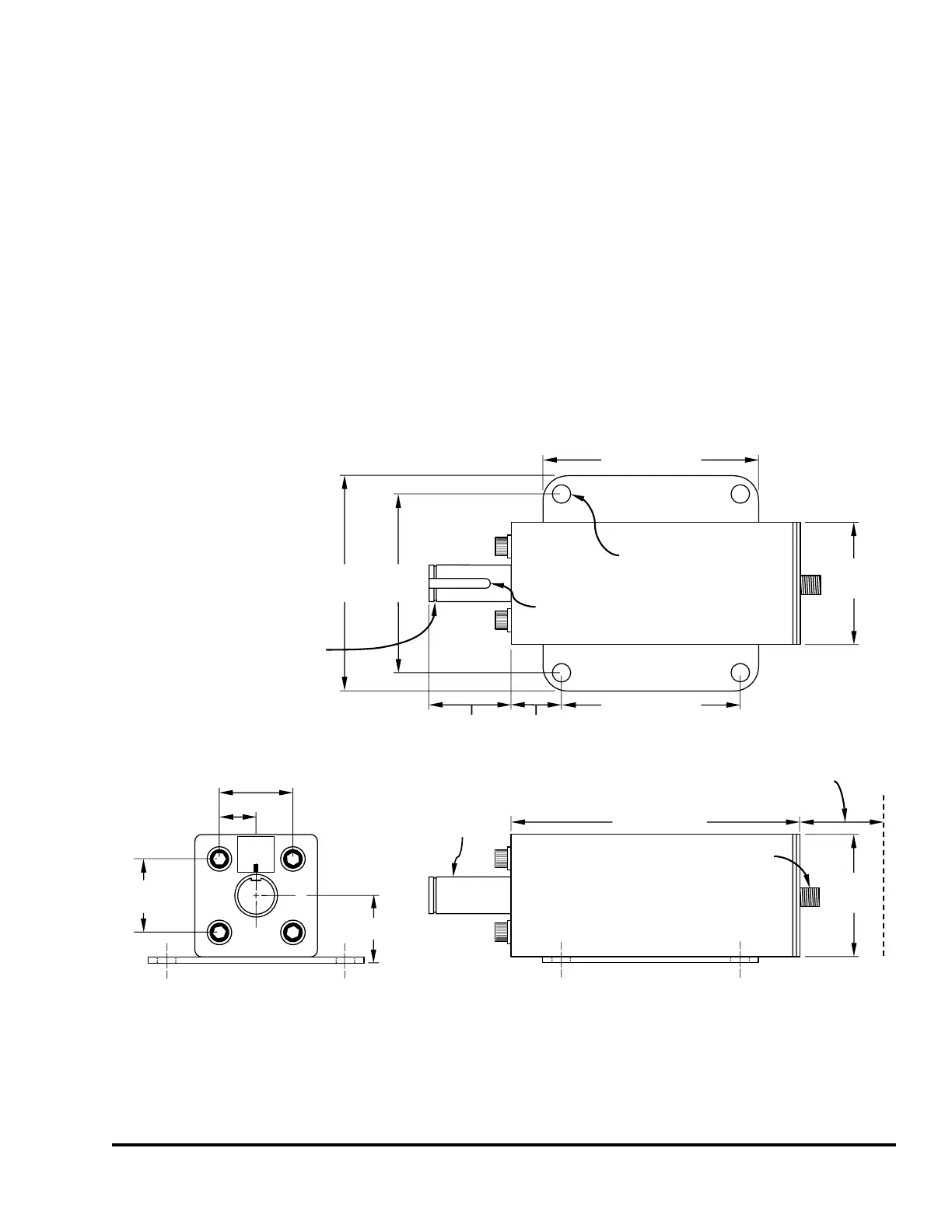

The following show dimensions for the 5100-11 as well as mounting dimensions when used in

conjunction with the spring base.

C

L

C

L

1.50” (38.1)

1.37”(34.8)

0.75” (19.1)

1.50”

(38.1)

1.015”

(25.8)

3.67” (99.2)

1.7”

(43.2)

Shaft

0.75” (19.1)

diameter

2.50”

(63.5)

5.9” (149.0)

0.375” (9.5)

diameter

(4 places)

2.50”

(63.5)

3.67”

(93.2)

4.40”

(111.8)

Circular

Connector

Allow 3.0” (76)

clearance for

mating connector

4.40” (111.8)

Values in

parentheses

are in millimeters

TOP

SIDE

3/16” (4.8) wide

by 1” (25.4) long

standard keyway

Clip Ring

Groove

5100-11

Encoder

Figure 72: 5100-11 Encoder Dimensions

Loading...

Loading...