Doc #: L-2600-1023 Page 6 Rev. 02

1 INTRODUCTION

The System 2600 is a

stand-alone die protection

and, optionally,

programmable limit switch

(PLS) unit that can be used

with any existing press

control. It serves two

primary purposes - die

protection and automation.

The die protection

capabilities of the System

2600 offer enough

flexibility to meet the needs

of almost any die protection

application.

The System 2600 features

six built-in die protection

channels which are

designed for use in

monitoring various material

and tool conditions that are important to the correct operation of the stamping process such as:

• Misfeed of the material (long feed, short feed, stock buckle)

• Verification of part ejection

• Stripper position

• Verification of slug ejection / detection of slug stacking

• End of stock

This is accomplished by installing appropriate sensors and probes in or near the die and connecting these

sensors to the die protection channel inputs of the operator terminal. The channels are then programmed

through the operator terminal to perform the desired monitoring function for the connected input. In the

event that improper conditions occur, the machine can be stopped, avoiding excessive delay in the

production process or damage to the tooling and/or press.

Either solid state (NPN or PNP) sensors or probes and mechanical sensors may be used to drive the

inputs. This is configurable on a per-channel and per-job basis so using a variety of sensors is a valid

option. Once configured, these settings will be automatically recalled with each job.

The System 2600 can be programmed to monitor each individual die protection input in the manner

necessary to ensure that the process is operating in the intended manner. Each channel can be

programmed to function as one of several logic types, which are covered in the configuration section.

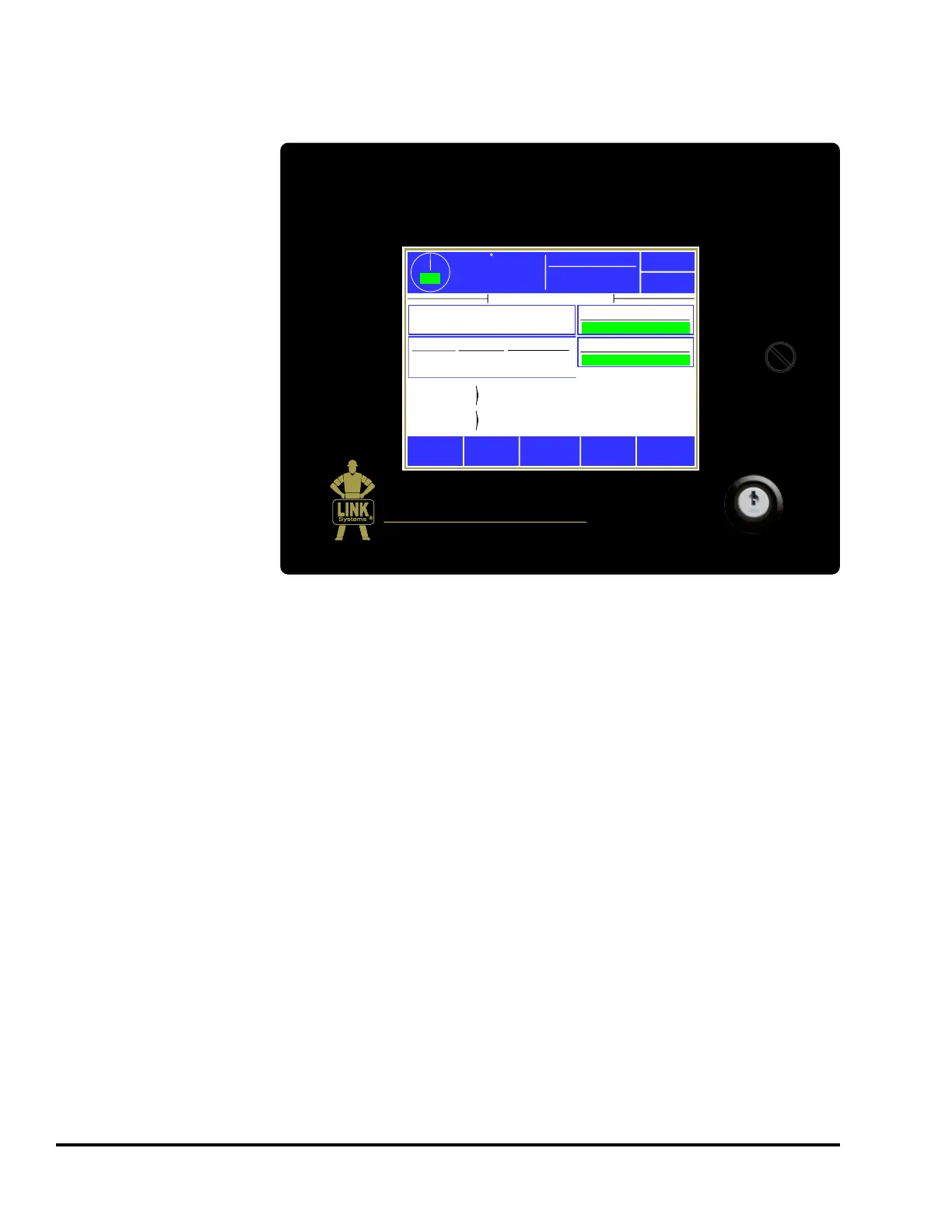

SYSTEM 2600

PLS/DIE PROTECTION

USE ONLY FINGERS TO OPERATE TOUCH SCREEN

LINK ELECTRIC & SAFETY CONTROL CO.

444

McNALLY DR. NASHVILLE, TN. 37211

359

TOP

Stroke Speed

0

SPM

Espanol

Diagnose

ACC

Reason for

the Last Stop

Running

Status

System 2600 Tonnage Monitor

Job: 1233

Lower Bracket

Die Protection

All Conditions OK

Counter

Count

Limit

Part

Batch

334

84

3000

250

Power Up

All Conditions OK

Mode: Production

Limit Switch

All Conditions OK

Loading...

Loading...