Doc #: L-2600-1023 Page 58 Rev. 02

“Motion Threshold” setting for a period of time greater than the “Loss of Motion Time”. The Loss of

Motion Time setting is used to compensate for erratic motion on some geared presses where the gears

cog back and forth as the press strokes, resulting in temporary dips below the Minimum Press Speed

SPM setting.

4.4.1 Engagement Time Limit

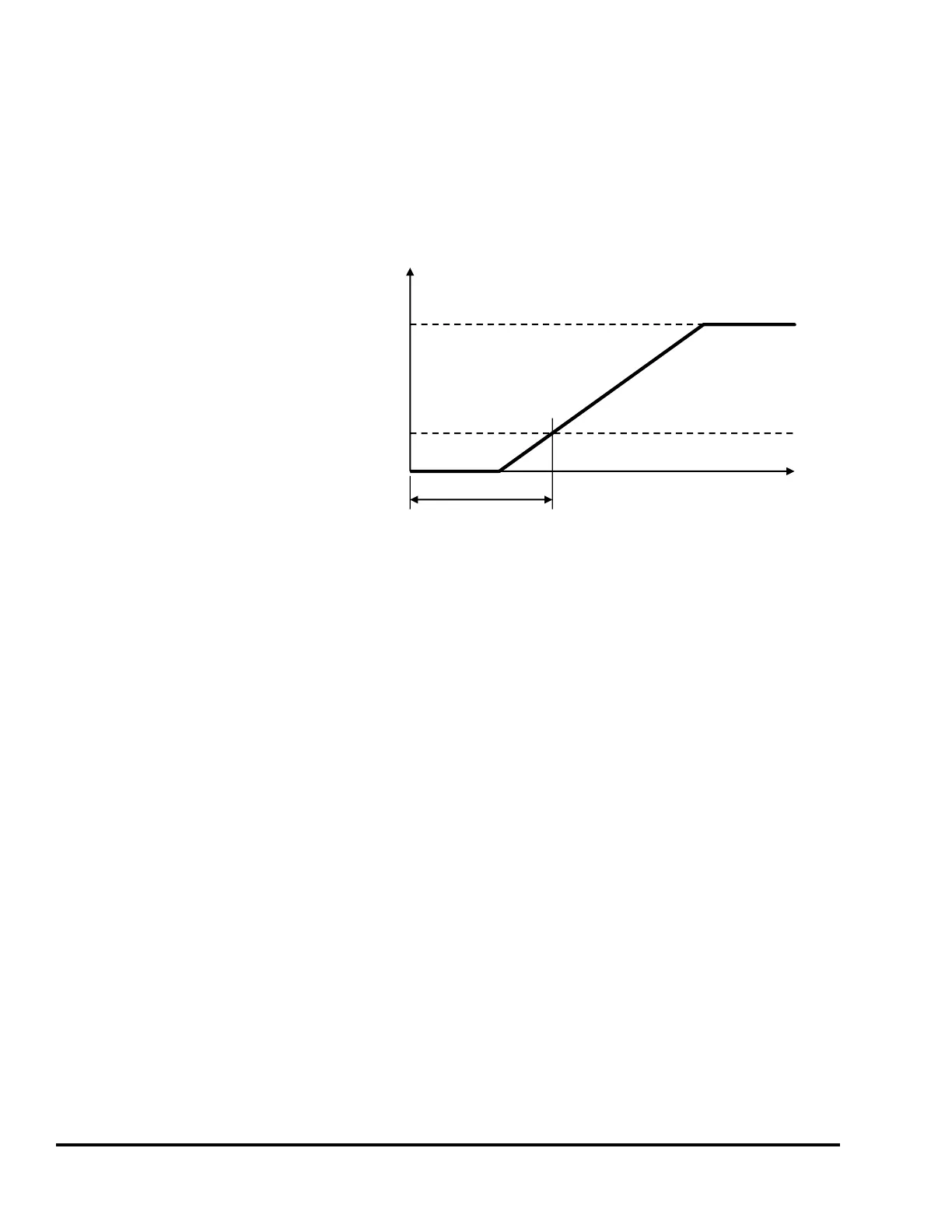

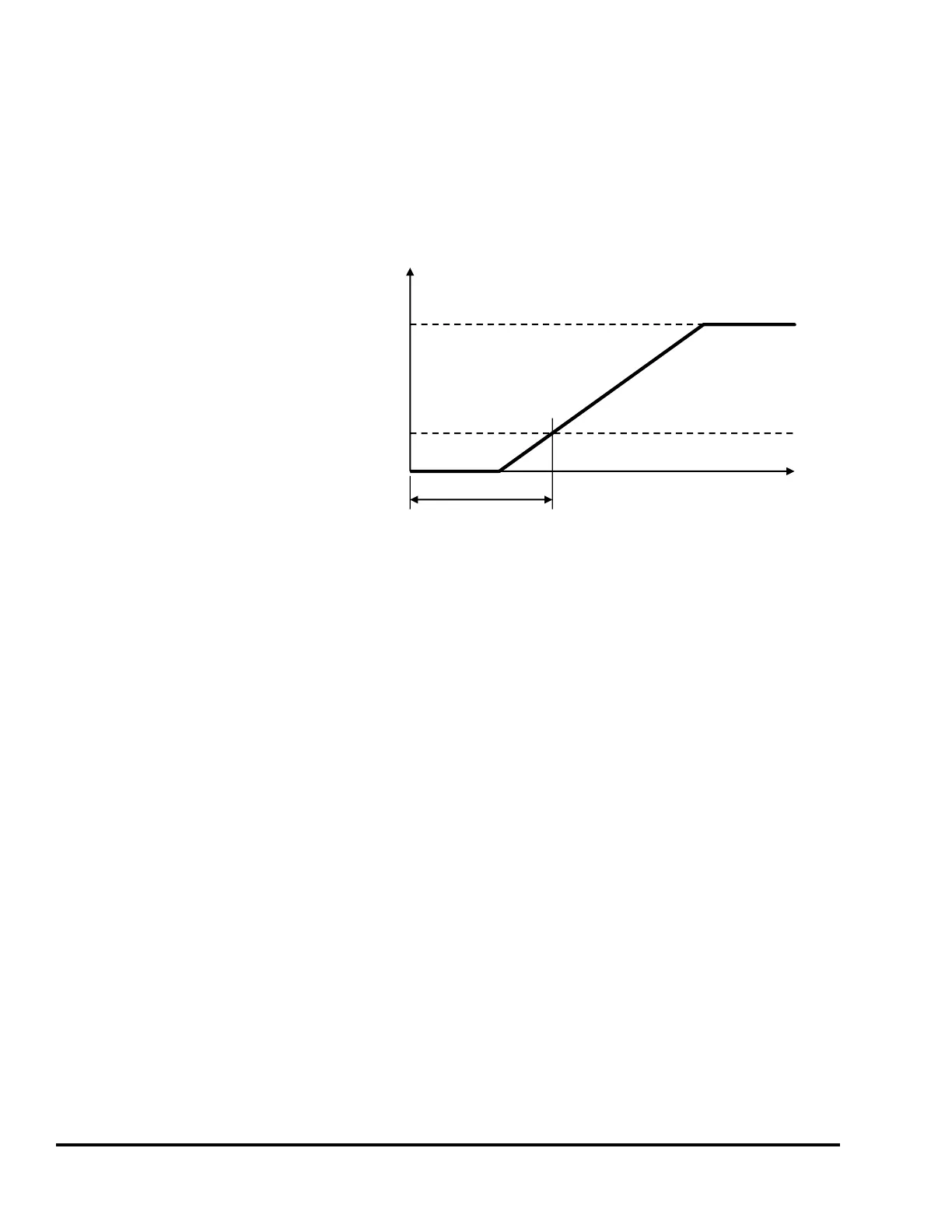

When the press control sends an electrical

signal to the clutch/brake valve(s) to start

stroking the press, there is a time delay

before the air flow (or hydraulic system on

some presses) can push the clutch plates

together and ramp up crank speed. Then

the clutch plates slip until the equivalent

flywheel SPM is reached. This is

illustrated in Figure 47.

Every time a stroke is initiated in the

forward direction, the press must establish

a stroking speed greater than the “Motion

Threshold” within the time set by the

“Engagement Time Limit”. Failure to do so will result in an immediate stop and the reason for last stop

will display Motion Did NOT Start. This parameter can be set from 0 to 999 milliseconds.

In addition to detecting faults, the “Engagement Time Limit” provides useful diagnostic information

relating to clutch wear. As clutch plates wear, the volume of air that must flow into and be stored in the

clutch increases, which also increases the engagement time. The increased volume of air stored in the

clutch also takes longer to flow out when the air valve dumps pressure to stop stroking, resulting in

longer stopping times for the press. Most presses provide for adjustment or shimming to compensate for

clutch wear. Exceeding the clutch “Engagement Time Limit” may indicate that clutch adjustment or

shimming should be performed. When possible, it is preferable to adjust the clutch clearance to the

press manufacturers recommended setting to determine the clutch engagement time with optimum

clearance.

To determine the value to enter as the “Engagement Time Limit”, first set the value to 999. This will

prevent stops while the correct time is being determined. Then put the press in Single Stroke Mode and

stroke the press several times. The “Last Actual” engagement time is displayed on this screen just to the

right of the “Engagement Time Limit”. Some margin for wear must be accommodated so that

adjustment on a frequent basis is not necessary. A typical wear margin of 20% is usually sufficient. To

determine the number to enter for the “Engagement Time Limit” with a 20% wear margin, take the

longest time actual engagement time observed and multiply it by 1.2. For example, if the longest actual

engagement time is 100 milliseconds, enter a value of 120 milliseconds (100 X 1.2 = 120) for the

“Engagement Time Limit”.

Clutch Eng. Time

Press SPM

Time

Flywheel Equivalent SPM

Motion Threshold

Figure 47: Clutch Engagement Time

Loading...

Loading...