Doc #: L-2600-1023 Page 50 Rev. 02

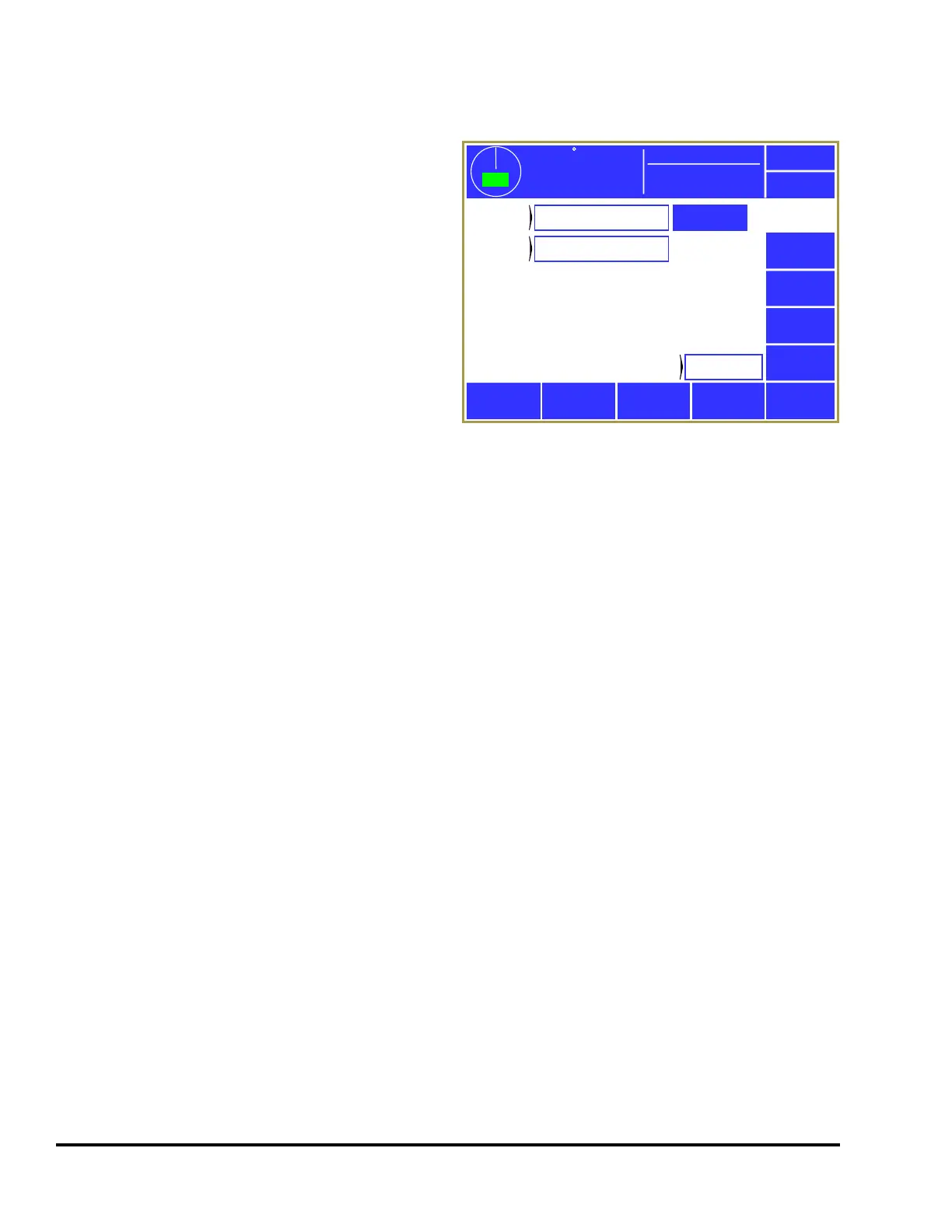

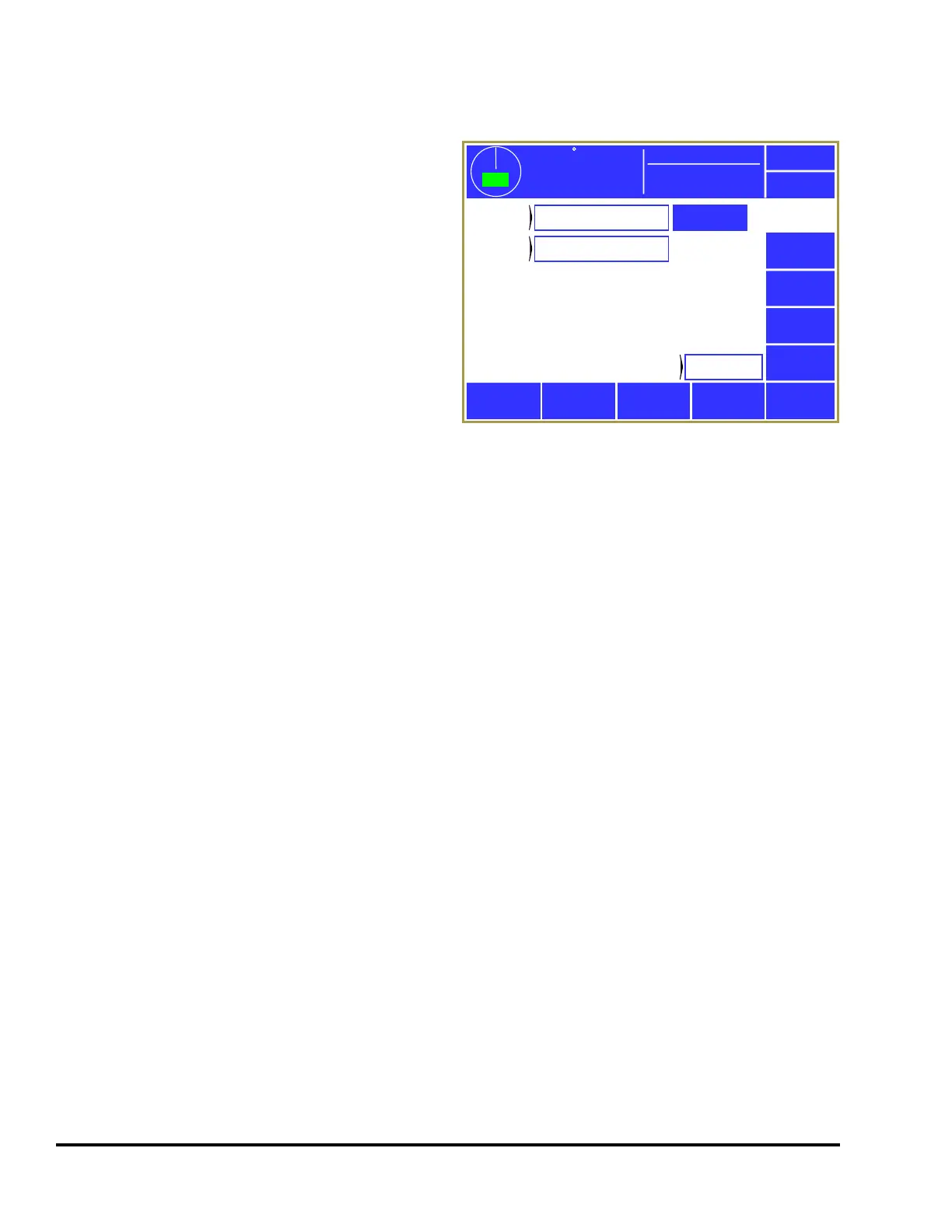

3.5.1 Configuring Production Counters

Up to 2 counter groups can be enabled on a job by

job basis. In other words, one job can have one

counter group enabled, while a second job can have

2 counter groups enabled. Cycle based counter

groups can also be set to increment by a particular

value every so many cycles rather than

incrementing by 1. To configure the counters, press

the Counter Settings softkey in the counter screen of

Figure 37.

A screen similar to Figure 39 will appear and

allows each counter group to be set to cycle based

counting, sensor-based counting, or not used.

Hitting the Configure System softkey in this screen

will bring up a screen with three settings –

“Maximum Number of Counter Groups”, “Enable True (Sensor Based) Part Counters”, and “Count in

Setup Mode”. These settings apply to the system as a whole instead of to a job. The maximum number

of counter groups can be set to 1 to 2 and will affect how many counter groups are shown in the screen

of Figure 39. If “Enable True (Sensor Based) Part Counters” is set to “No”, then “Sensor Based” will

not be available to choose as counter group type. Both of these settings are present to allow a reduction

in the number of settings presented to operators for features that are not used. Finally, “Count in Setup

Mode” controls whether cycle based counters will count when a “setup mode” is active.

Counter groups that are set to “Cycle Based” also have a Configure button shown to the right of the

group (as seen in Figure 39 for Counter Group 1). When pressed, a screen will appear that allows the

“Counter Increment” and “Counter Frequency” to be set. The “Counter Increment” is how much the

counter will be increased when a count occurs. For instance, a job producing two parts per cycle would

count by 2 every 1 cycle. The “Counter Frequency” is how often the counter should count. A

lamination die might produce a part every 10 cycles. If a lamination die with 10 laminations was also a

2 out die, the “Counter Frequency” would be set to 10, and the “Counter Increment” would be set to 2.

The counter would then count by 2 every 10 cycles. For typical one-out jobs, both of these values

would be 1, which would count by 1 every 1 cycle.

If a counter group is set to “Sensor Based” then it is driven by one or more die protection inputs. For

those die protection channels types that have “Increment Counter” settings that are set to the counter

group, the counter will increment when the channel senses a part.

3.5.2 Production Counters

The three production counters provided are Part, Batch and Quality. All production counters that are

turned “On” will increment as the press strokes.

359

TOP

Stroke Speed

0

SPM

ACC

Espanol

Exit

Counters

Configure

Counter

Group 1

Cycle Based

Counter

Group 2

Sensor Based

Configure

System

Job Hit

Count

509

Mode:

Production

Figure 39: Counter Configuration Screen

Loading...

Loading...