Doc #: L-2600-1023 Page 59 Rev. 02

4.4.2 Motion Threshold

Press SPM must exceed the “Motion Threshold” after stroke initiation if the main motor is running in

the forward direction (see Figure 47 for the relationship between “Engagement Time” and “Motion

Threshold”). Failure to establish motion will result in an immediate stop and the reason for the last stop

will display Motion Did NOT Start.

It must also maintain motion above this limit while the press is stroking (see also “Loss of Motion

Time” and Figure 48). Failure to maintain motion above this threshold while stroking will result in an

immediate stop and the reason for last stop will display Motion Stopped. Whenever slide motion is at

rest and the press control is not energizing the clutch/brake valve(s), crankshaft motion must remain

below this threshold. If motion above the threshold occurs for greater than 250 milliseconds it will

result in a stop and the present running status will display Motion w/o Clutch Signal.

This parameter can be set from 0 to 255 SPM and generally should be set 10% to 30% below the slowest

normal stroking speed of the press.

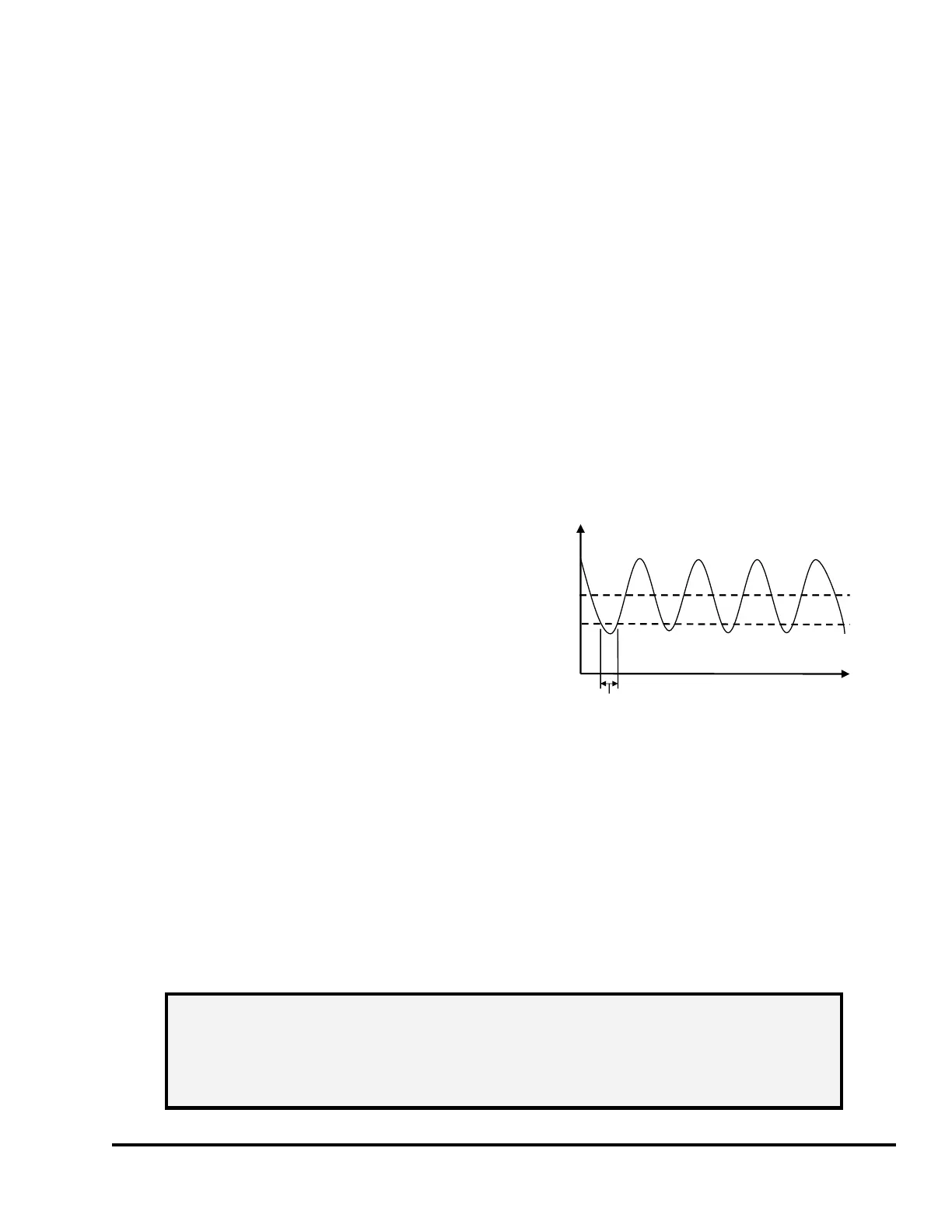

4.4.3 Loss of Motion Time

The “Loss of Motion Time” is provided

because mechanical backlash of drive

system components can cause the

crankshaft to turn in a jerky motion,

falling below the motion threshold for

very brief periods of time. Figure 48

shows an exaggerated illustration of this.

The “Loss of Motion Time” setting is

chosen to prevent nuisance stopping by

permitting press SPM to drop below the

“Motion Threshold” for brief periods of

time without the assertion of a stop.

For typical applications this parameter should be set to:

Time (in milliseconds) = 3500 / Max SPM

For example, if the press maximum speed is 100 SPM, then this value would be set to:

3500 / 100 = 35 milliseconds

Like wise a press with a maximum speed of 20 SPM would be set to:

3500 / 20 = 175 milliseconds

Press SPM

Time

Average SPM

Motion Threshold

Loss of Motion

Figure 48: Loss of Motion Time and Motion Threshold

NOTE: If the loss of motion time value calculated by the formula is shorter than the

time that motion can dip below the “Motion Threshold”, loss of motion

faults will result. If these occur, you may increase the time calculated by the

formula but, in no case should this time be increased more than 2.5 times

the value calculated by the formula.

Loading...

Loading...