Chapter 10. Maintenance

10-1

Chapter 10. Maintenance

Be sure to perform daily and periodic maintenance and inspection in order to maintain the PLC in the best conditions.

10.1 Maintenance and Inspection

The internal circuit of the XGT Panel mainly consist of semiconductor devices and its service life is semi-permanent. However,

periodic inspection is requested for ambient environment may cause damage to the devices. When inspecting one or two times

per six months, check the following items.

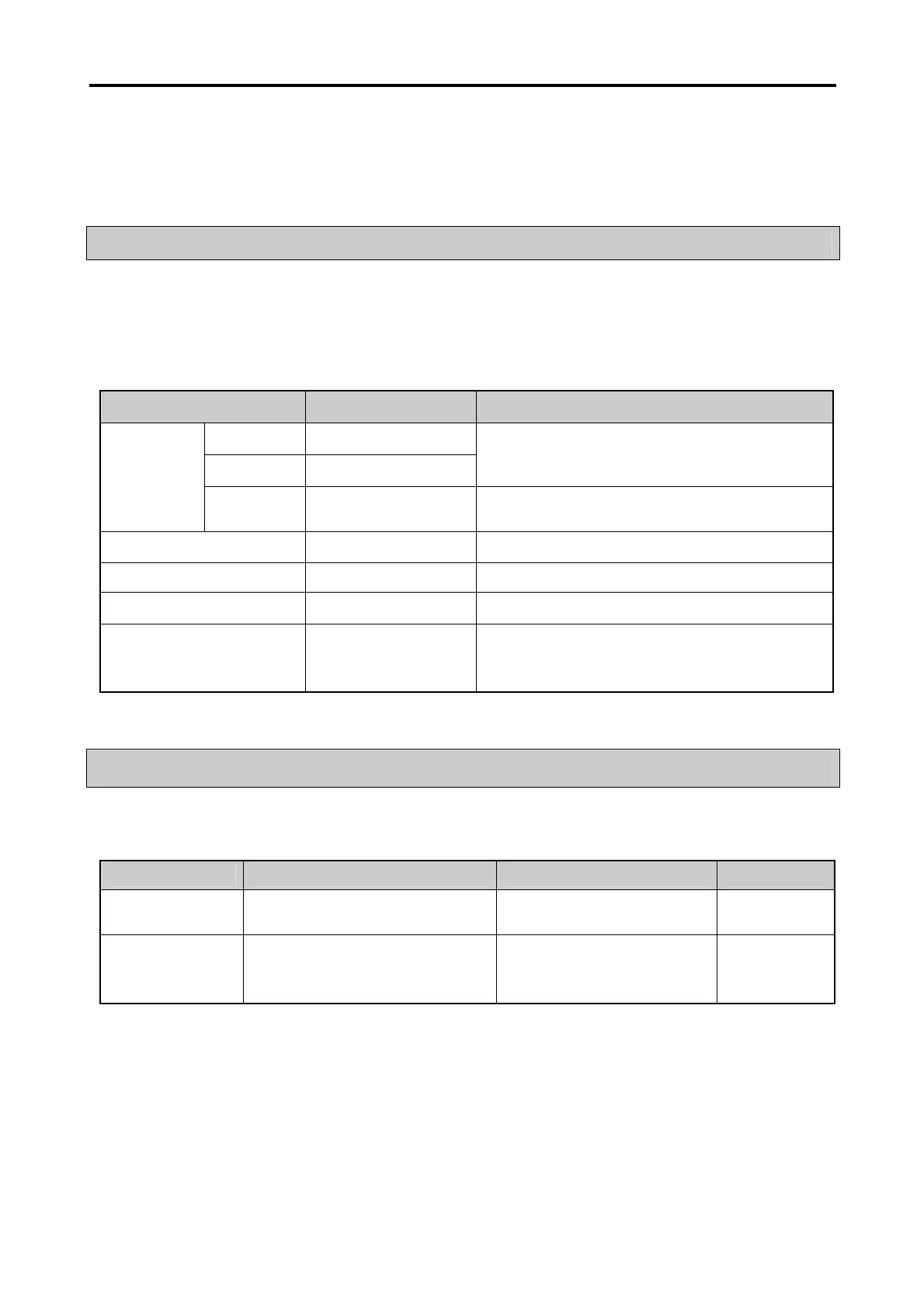

Check Items Judgment Countermeasure

Temperature

-20 ~ 60°C

Humidity 5 ~ 85%RH

Adjust the operating temperature and humidity with the

defined range.

Ambient

environment

Vibration No vibration

Use vibration resisting rubber or the vibration prevention

method.

Shaking of the XGT Panel No shaking allowed Fix the XGT Panel

Screws connecting conditions No loose allowed Retighten terminal screws.

Change rate of input voltage

− 15% to 10%

Hold it with the allowable range.

Spare parts

Check the number of

Spare parts and their

Store conditions

Cover the shortage and improve the conditions.

10.2 Daily Inspection

The following table shows the inspection and items which are to be checked daily.

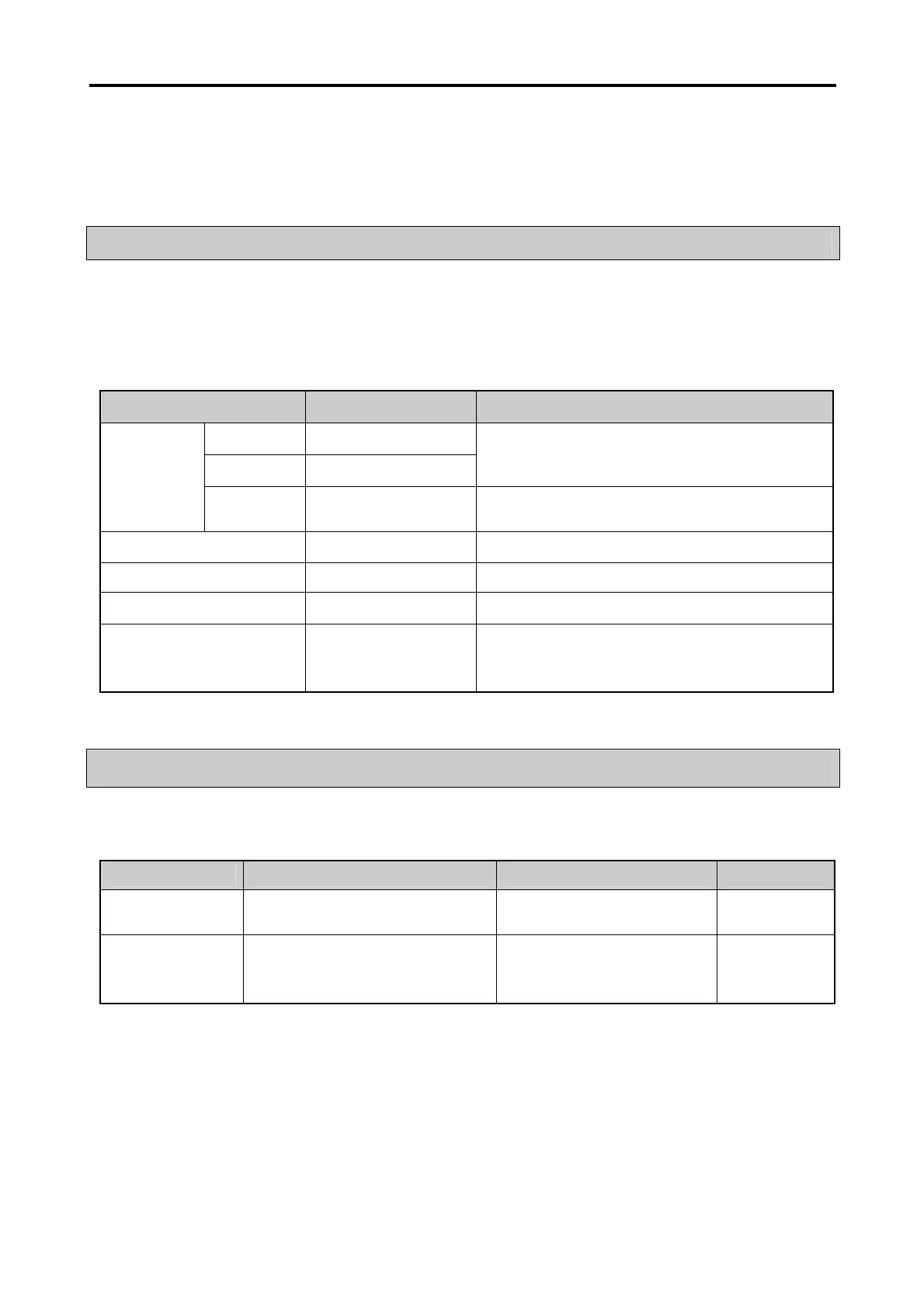

Check Items Check Points Judgment Countermeasure

Terminal block

connecting conditions

Check for loose mounting screws Screws should not be loose Retighten Screws

Communication

connector connecting

conditions

Check the connector falling Connectors should be fixed

Retighten Screws

Loading...

Loading...