4-17

[INSTALATION WINCH WIRE ROPE]

Be sure to attach the rope wedge properly to secure the wire rope. Potential serious accident

may occur due to detachment of the wire rope during crane operation if disregarded.

CAUTION

• Avoid irregular winding of the wire rope in the winch drum.

• Always hoist an object (2.9 to 4.9KN {300 to 500kg}) with the boom extended and raised fully

immediately after attaching a new rope. Repeat raising and lowering the hook several times

until the new rope conforms.

• The wire rope is coiled. Exercise caution not to form a kink in the rope when winding it up.

Be sure to unrope by rotating the rope to pull it out of the winch drum.

Use the following procedure to attach the wire rope.

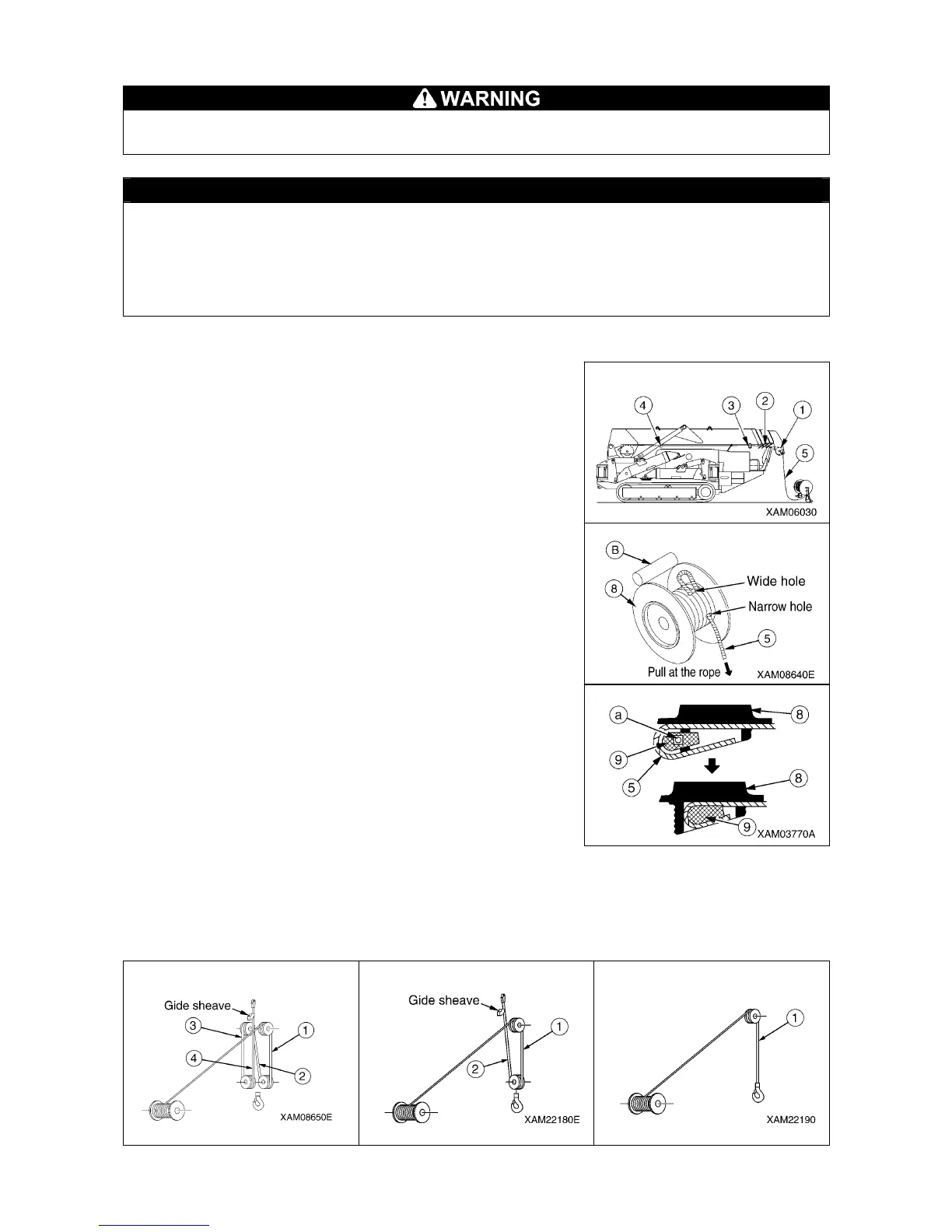

1. With the end of the wire rope held, draw the wire rope (5)

through the weight of the over hoist detector, load sheave (1) at

the boom end, wire guide (2) of No.2, 3, and 4 boom, snap

sheave (3), and idler sheave (4).

2. Draw the wire rope (5) through the attachment hole of the winch

drum (8). Secure the wire rope (5) to the winch drum (8),

following the procedure provided below.

(1) Draw the wire rope (5) through the winch drum (8) with the

rope loose.

(2) The rope wedge (9) should be in position (a). Pass the wire

rope (5) around the rope wedge and yank at the rope in the

direction indicated by the arrow.

Adjust the length of the wire rope (5) to keep the end of the

wire rope from protruding from the narrow hole in the winch

drum (8).

3. Place the winch lever in the “Up” position (pull it toward you)

slowly to wind up the wire rope (5) in the winch drum (8).

Ensure that the wire rope is coiled between the irregular winding

protective roller (B) and winch drum. The wire rope needs to jut

out the boom end (approx. 10m).

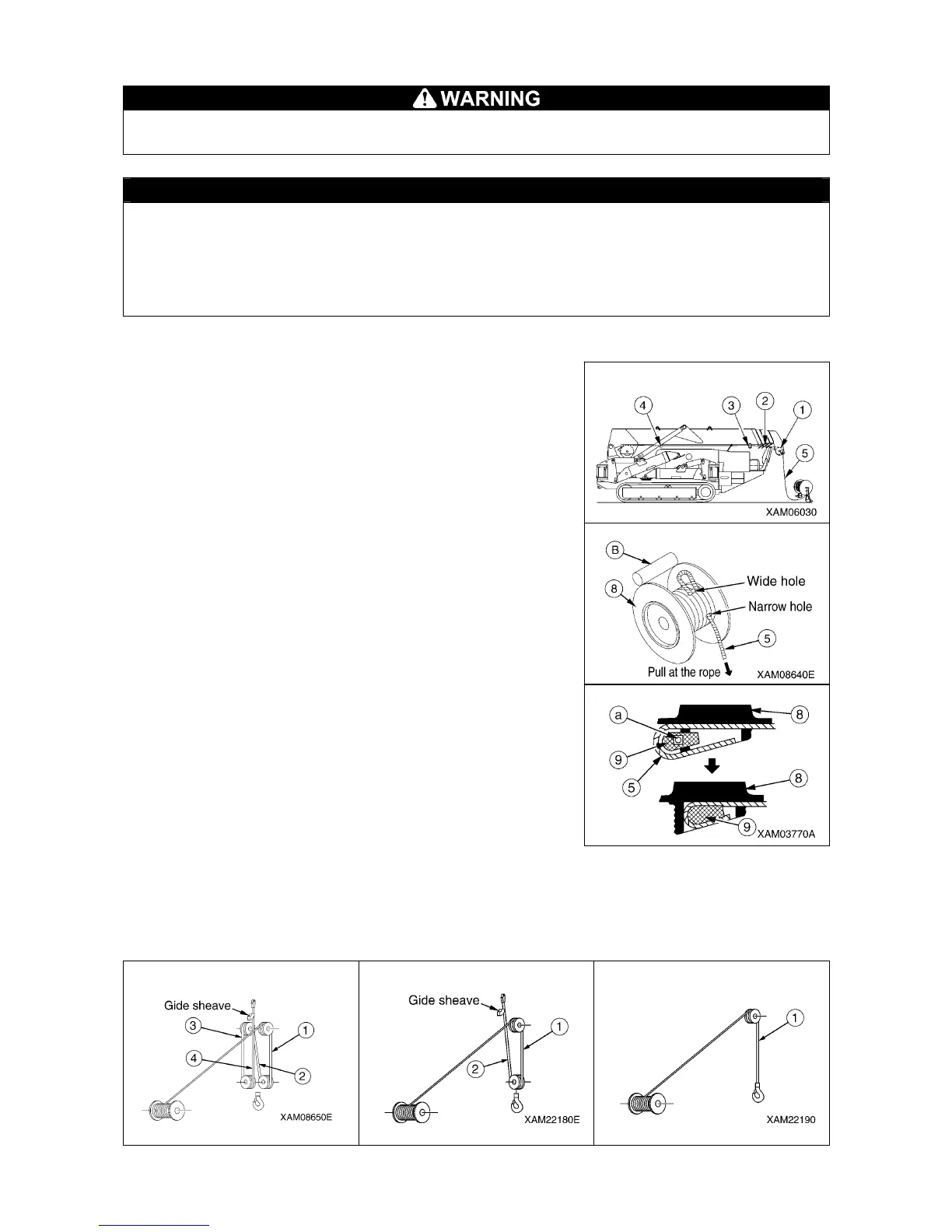

4. In response to the number of falls, draw the wire rope through

the load sheave at the boom end, hook block sheave, guide

sheave, and retraction cam.

4-falls

2-falls 1-fall

Loading...

Loading...