4-43

[5] OIL REPLACEMENT IN WINCH REDUCTION GEAR CASE

Oil will be at elevated temperatures immediately after engine operation, which urges you not to

unplug the inspection port and drain port. Unplug the port with the oil cold.

CAUTION

• See “Maintenance 5.1 Use of Lubricating Oil According to Temperature” for which oil to be

used.

• Use seal tape, etc. at the thread of the plug to stop the oil leak and securely tighten the plug

after refilling with the oil.

• Oil drain pan: A 1-liter container

• Hexagonal wrench for plug removal: 8mm

• Quantity of oil for replacement: 0.75L

1. Place the machine on a level surface.

2. See “Operation 2.14 Outrigger Setting Operation” to rotate the

rotary of the “outrigger (1)” outward.

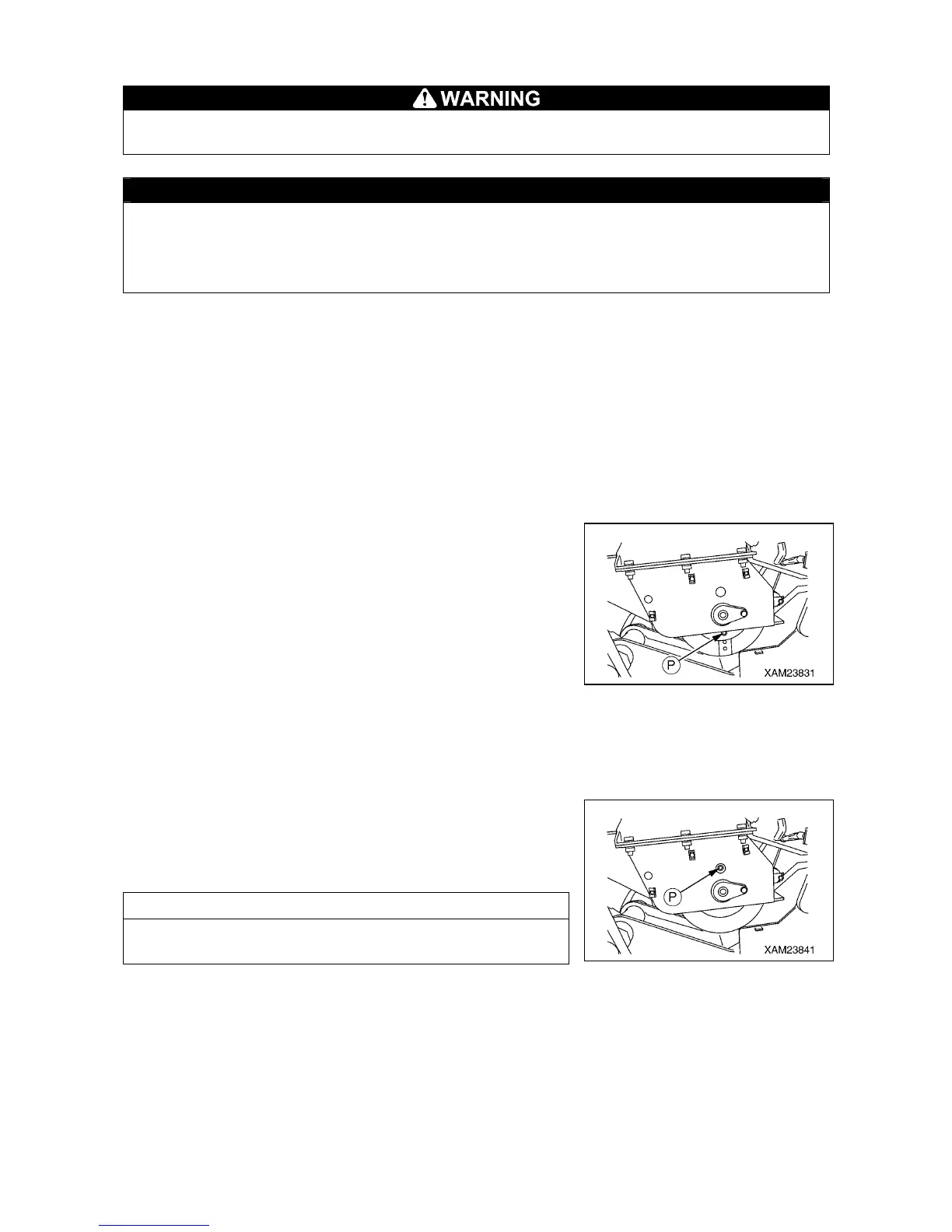

3. Slowly rotate the winch until the plug (P) is visible, and once the

plug (P) is visible, set the plug (P) to the lowest position.

4. Place a drain pan directly under the plug (P) to receive drained

oil.

5. Use the hexagonal wrench to remove the plug (P). The gear oil

is drained from the winch reduction gear case upon plug

removal.

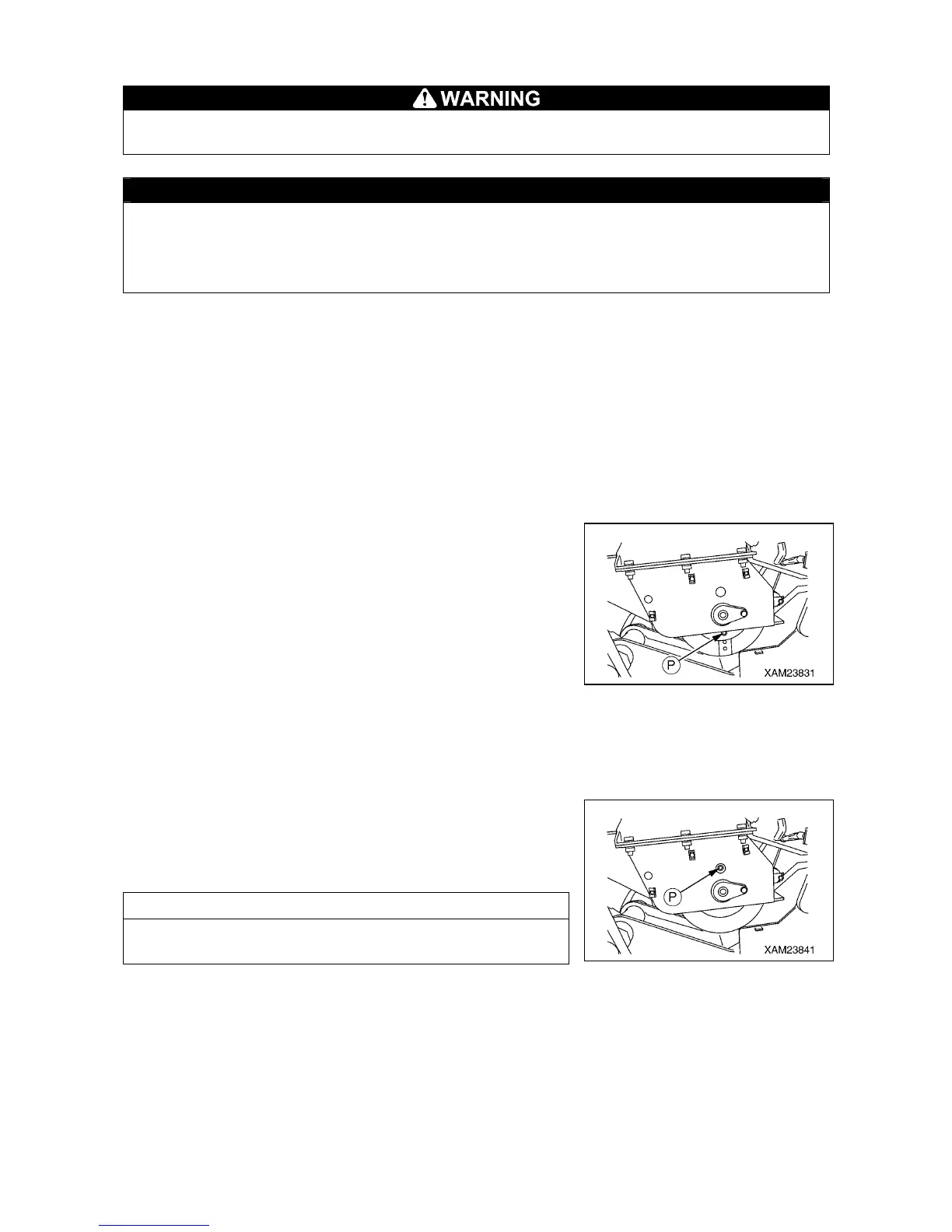

6. Once the gear oil is fully drained out of the winch reduction gear

case, rotate the winch slowly until the plug (P) hole is visible

through the hole above the pin.

7. Replenish the standard amount (0.75 liters) of gear oil using an

oil pump or similar tool through the plug (P) hole.

NOTES

Wipe off the oil completely if spilled.

8. Put in the plug (P) and secure it upon completion of oil

replenishment.

9. See “Operation 2.24 Outrigger Stowing Operation” to stow the

“outrigger (1)”.

Loading...

Loading...