4-44

[6] OIL REPLACEMENT IN TRAVELING MOTOR REDUCTION GEAR CASE

CAUTION

• See “Maintenance 5.1 Use of Lubricating Oil According to Temperature” for which oil to be

used.

• Use seal tape, etc. at the thread of the filler plug to stop the oil leak and securely tighten the

plug after refilling with the oil.

• Oil drain pan: A 1-liter container

• Quantity of oil for replacement: 1.0L

1. Place the machine on a level surface.

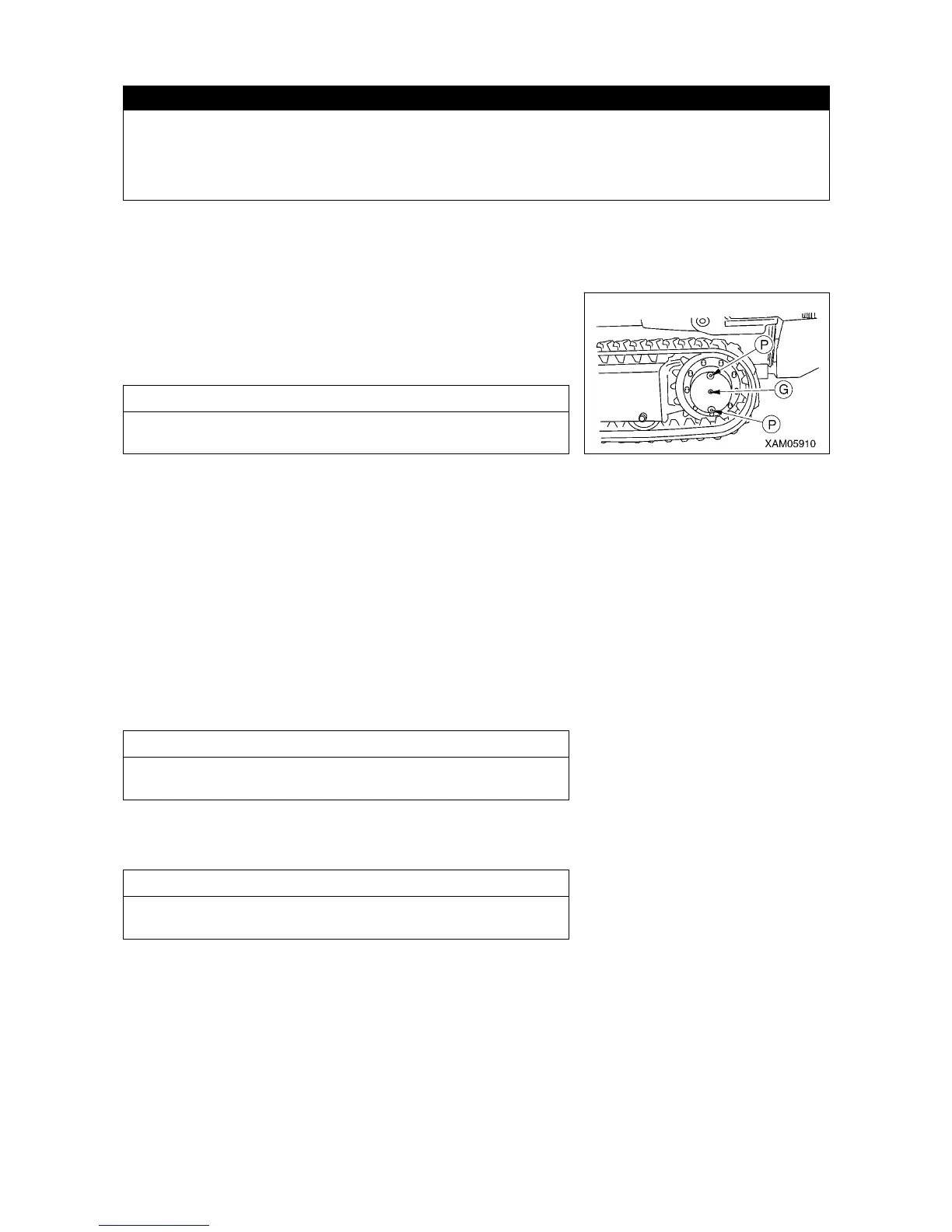

2. Move the machine forward and backward to position it

immediately above the drain plug (P) of the traveling motor

reduction gear case.

NOTES

This machine is equipped with two drain plugs (P). Either drain

plug must be positioned directly underneath the machine.

3. Place a drain pan directly under the lower drain plug (P) to

receive drained oil.

4. Remove the upper drain plug (P) and oil inspection plug (G).

5. Remove the lower drain plug (P) slowly to drain the oil, keeping

from contact with draining oil.

6. Check the drained oil. If check finds a considerable amount of

metal powder and foreign objects, contact our sales service

agency.

7. Put in the lower drain plug (P) and secure it.

8. Supply the gear oil to the traveling motor reduction gear case

through the upper drain plug hole (P).

NOTES

Pour in the gear oil until the oil comes out of the oil level check

plug (G).

9. Put in the upper drain plug (P) and oil inspection plug (G), and

secure them after oil replenishment.

NOTES

Wipe off the oil completely if spilled.

[7] INSPECTION/ADJUSTMENT ENGINE VALVE CLEARANCE

Inspection and adjustment of valve clearance require special tools.

Contact us or our sales service agency to request inspection and repair.

Loading...

Loading...