ASSEII'BLY

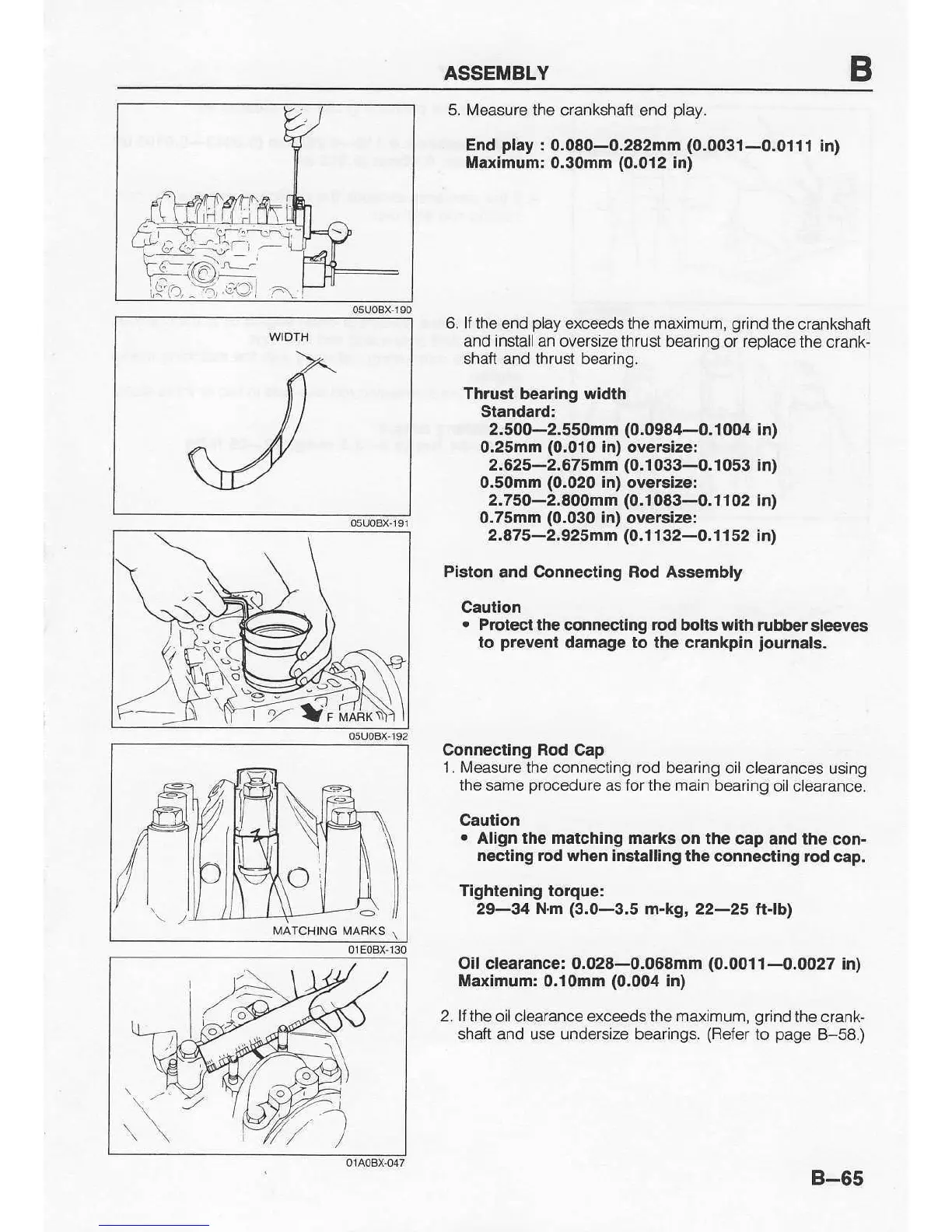

5. l\4easure the

crankshaft end

play.

End

play

: 0.080-0.282mm

(0.0031-0.0111

In)

Maximum:

0.30mm

(0.012

in)

6.

lf

the end

play

exceedsthe maximum,

grind

the crankshaft

and installan oveasize thrust bearing

or replace the crank-

shaft and thrust bearing.

Thrust

beadng

width

Standard:

2.500-2.550mm

(0.0984-0.1

004

0.25mm

(0.0t0

ln) overaize:

2.625-2.675mm

(0.1033-0.1053

0.50mm

(0.020

in)

ove6ize:

2.750-2.800mm

(0.1083-0.1

102

0.75mm

(0.030

in)

oversize:

2.875-2.925mm

(0,1

132-0.1152

Pision

and Conneciing Rod Assembly

in)

in)

tn)

in)

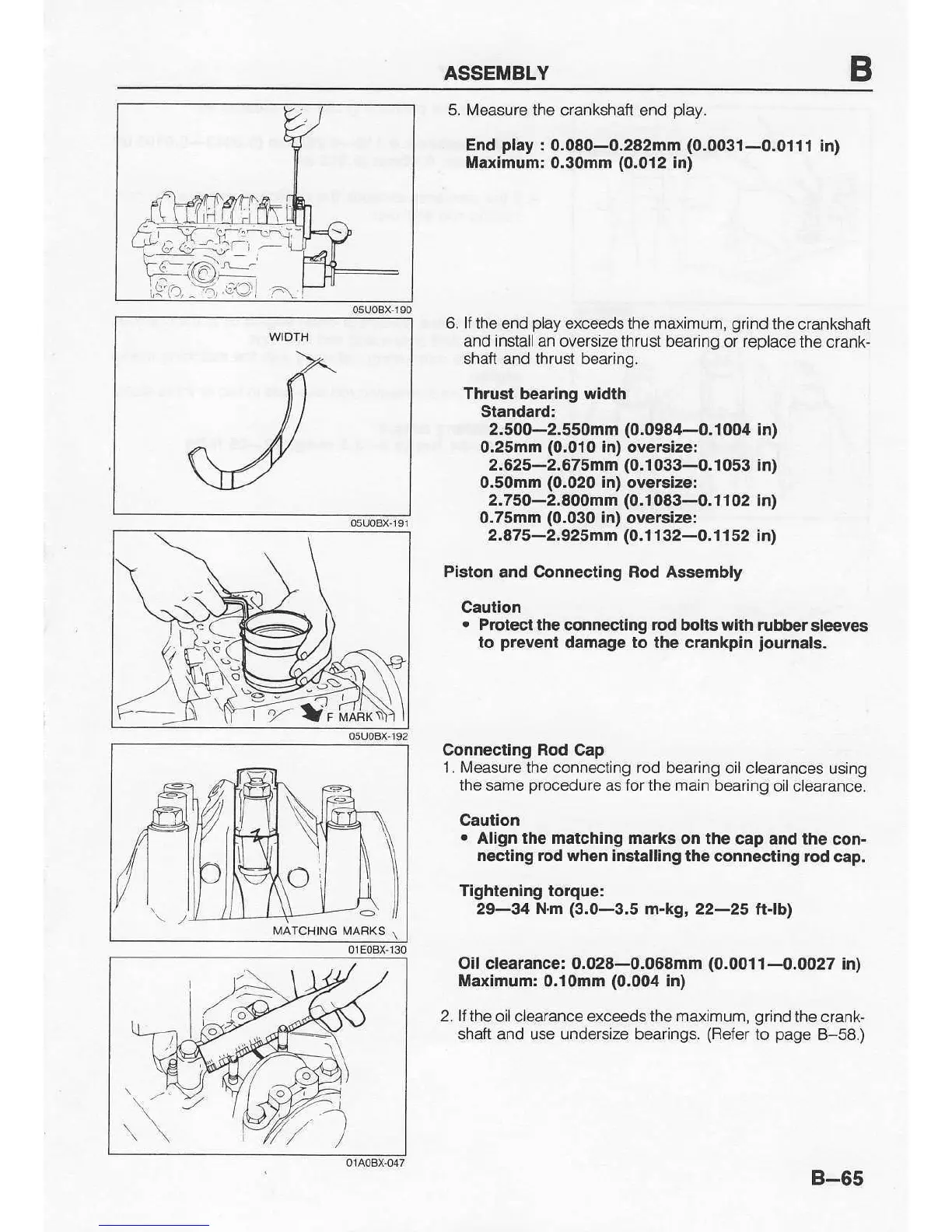

MATCHING MAFKS

Cautlon

.

Prolect

the connecting rod bolts with rubber

sleeves

to

prevenl

damage to the crankpin

iournals.

Connectlng

Rod

Cap

'1.

[/easufe the connecting rod bearing

oil clearances usang

the same

procedure

as for the main bearing

oilclearance.

Caution

.

Align lhe matching marks

gn

lhe

cap and the

con-

necting rod when installing

the connecting rod

cap.

Tighlening torque:

29-34

N.m

(3.0-3.5

m-kg, 22-25 ft-lbl

Oil clearance: 0.028-0.068mm

(0.001

1-0.0027 in)

Maximum:

0.lomm

(0.004

in)

2. lfthe

oilclearance exceedsthe

maximum,

grind

the crank-

shaft and use

undersize

bearings.

(Refer

to

page

B-58.)

(_.

:/:\

,.-

|Qro.

y

oe,l

rl

t'r

\'rinl|*

B-65

Loading...

Loading...