FUEL SYSTEiI

F

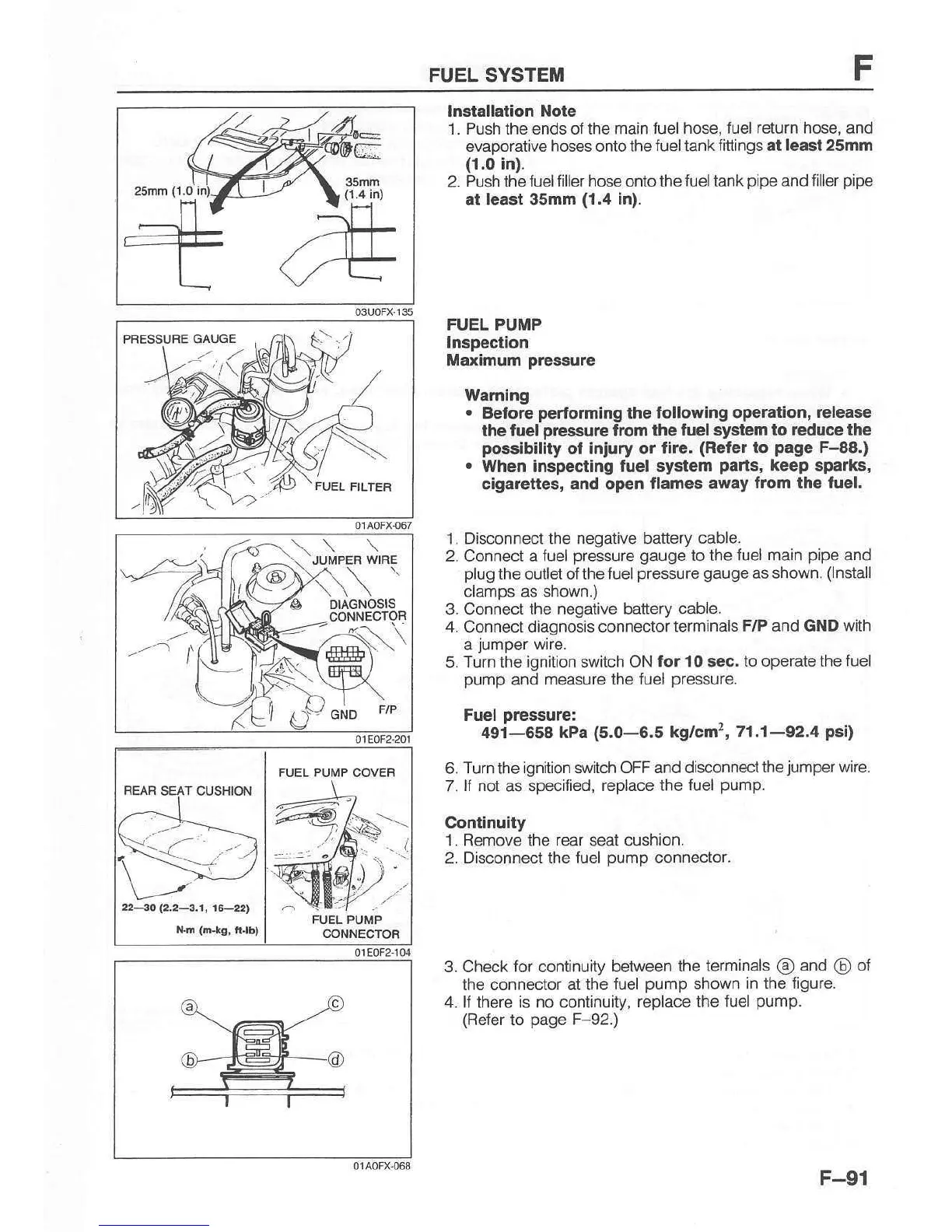

lnstallation Note

1. Push the ends of the main

fuel hose, fuel return hose, and

evaporative

hoses onto the

fuel

tank

fittings ai least 25mm

(r.0

in).

2.

Push thefuelfiller hose onto the tueltank

pipeand

tiller

pipe

al least 35mm

(1.4

In).

FUEL PUMP

Inspection

ltlaximum

pressure

Warnlng

.

Setore

performing

the

lollowlng operalion,

release

the tuel

prcssu|e

lrom the

fuel system to

r€duce

the

po$lbllily

ol Inlury or

lire.

(Reter

lo

page

F-{8.}

.

When inspecting luel system

palts,

keep sparks,

cigarettes,

and open tlames away

from the fuel,

'1.

Disconnect the negative baftery

cable.

2. Connect a fuel

pressure gauge

to the luel main

pipe

and

plug

the outlet of the fuel

pressure gauge

as shown.

(lnstall

clamos as shown.)

3. Connect

the negative battery cable.

4.

Connect

diagnosis connector terminals

F/P and GND with

a

lumper

wre.

5.

Turn

the

ignition switch ON tor l0 sec.

to operate the luel

pump

and

measure the fuel

pressure.

Fuel

pressure:

491-658 kPa

(5.0-6.5

kg/cm',

7l.l-92.4

p6i)

6.

Turn

he

ignition switch OFF and disconnect

ttte

jumper

wire.

7.

lf not

as

specified, replace the

fuel

pump.

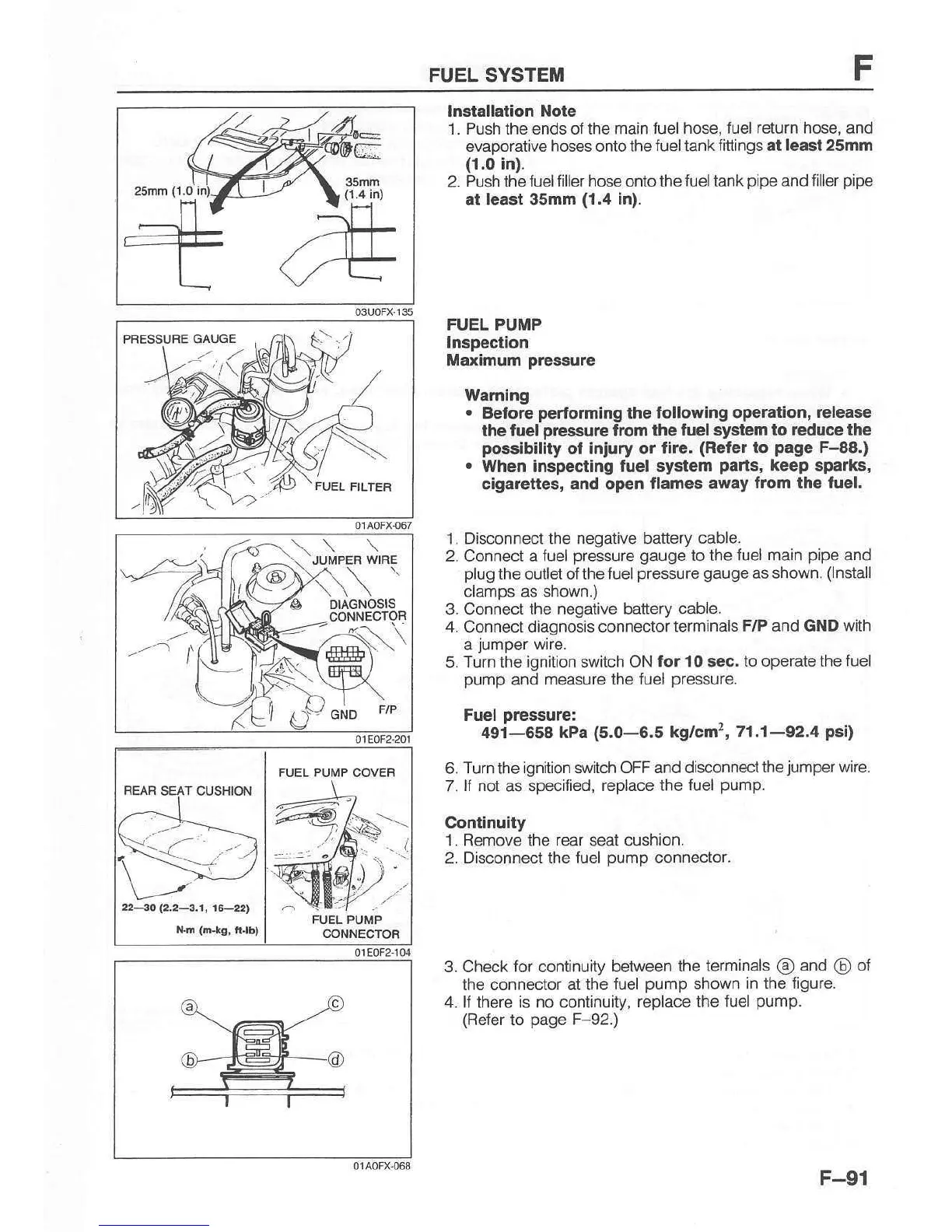

Conlinully

1. Remove the rear seal cushion.

2. Disconnect the fuel

oumD

connector.

3. Check lor continuity between

the terminals

@

and

@

of

the connector at the

fuel

pump

shown

in

the

figure.

4. lf there is no continuity, replace

the fuel

pump.

(Refer

to

page

F-92.)

FUEL PUMP COVER

REAN

SEAT CIJSHION

22--.30

12.2-3,

1, 1G-2'

Nfl

(Gks,

n.D)

|

CONNECTOB

F-91

Loading...

Loading...