INSPECTION

/

REPAIR

___n_

o

c2

So

z/-I\"

r"-

$\1-l^

o\ 4o

-L__-r-

H

o7

so

71"1--\v

Os-to

ry

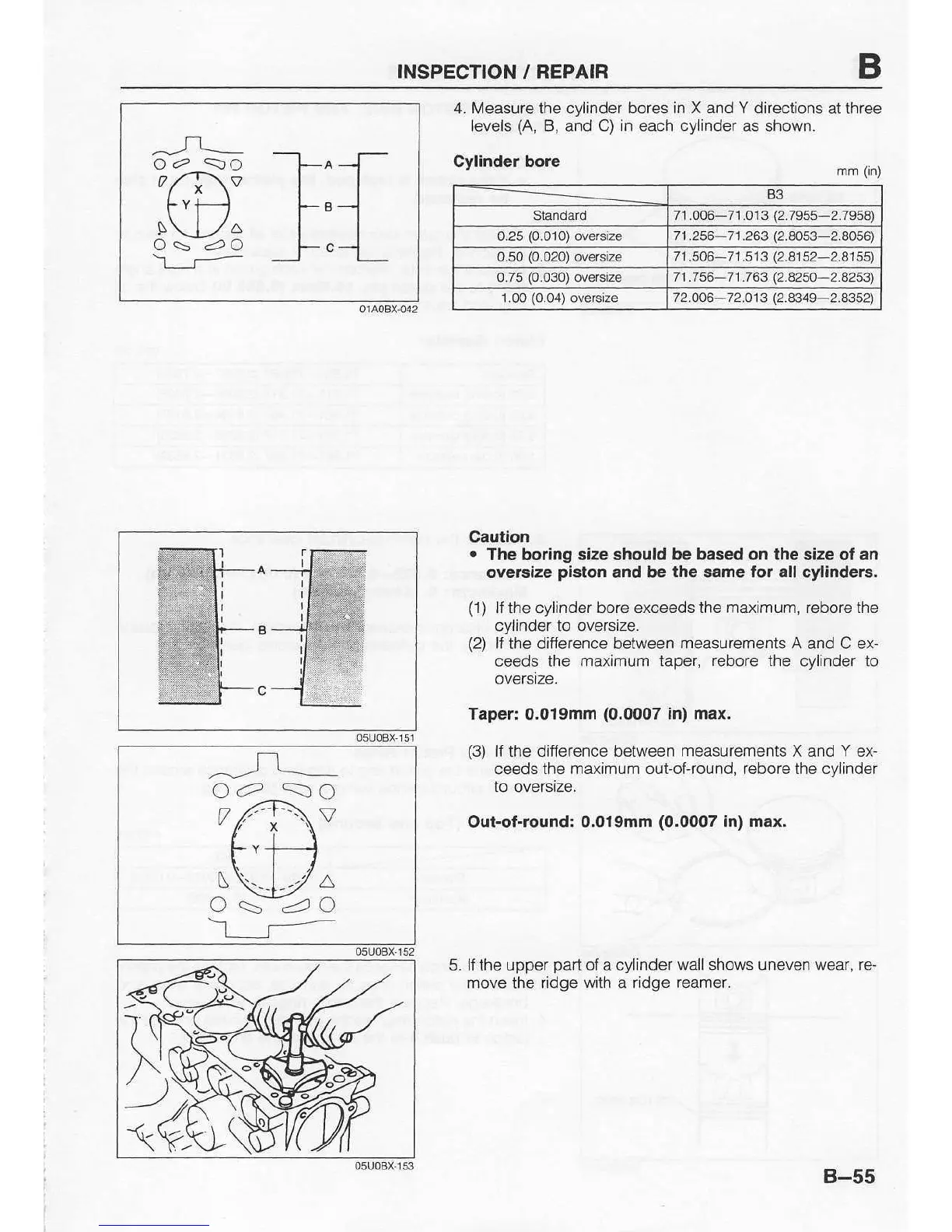

4. Measure the cylinder bores in

X

and Y directions at ihree

levels

(A,

B, and C) in each cylinder as shown.

Cylinder bore

mm (rnl

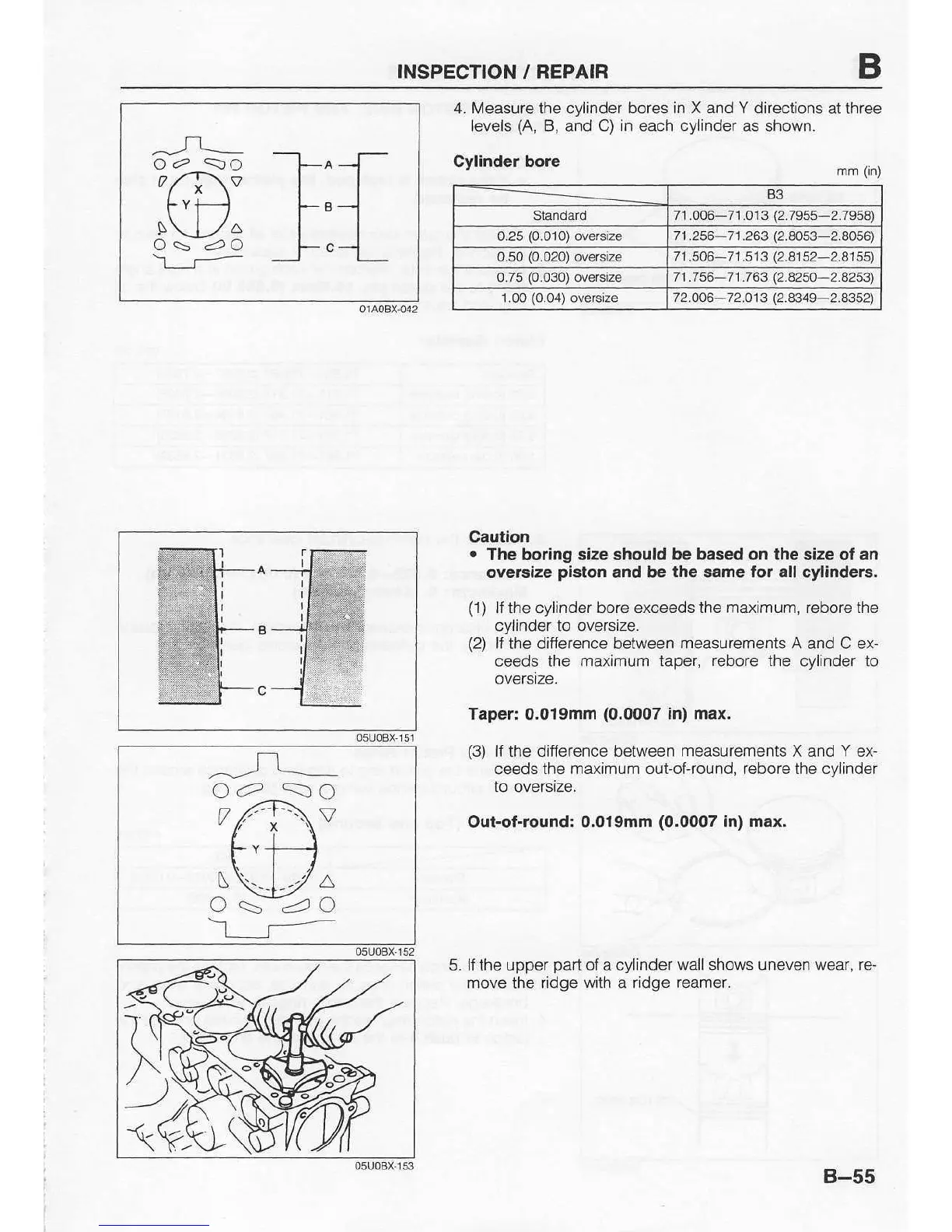

Caution

.

The boring size should

be based on the

size of an

overslze

pislon

and be

the

same

tor all

cylinders.

(1)

lf

the cylinder

bore exceeds the maximum, rebore the

cylinder to oversize-

(2)

If the difference between measu.ements A and C ex-

ceeds the maximum taper,

rebore

the cylinder to

overslze.

Taper:0,01gmm

(0.0007

in) max.

(3)

lf the difierence between measurements X and Y ex'

ceeds

the maximum outof-round, febore ihe cy{inder

to oversrze.

Out-ol-round: 0.01gmm

(0.0007

in) max.

5. lfthe upper

part

of a cylinder wall shows uneven wear,

rnove the ridge

with

a

ridge reamer.

B3

Slandard 71.006-71.01 3

(2.7955-2.7958)

0-25

(0.010)

oversize 7 1.256-7 1.263

12.8053,2.4056)

0.s0

(0.020)

overcize

71.506-71.513

12.8152

2.81

55)

0.75

(0

030) oversize

7 t.756-71.763

(2.8250

2.8253)

1.00

(0.04)

oversEe 72.046 72.01 3

12.8349-2.4352)

B-55

Loading...

Loading...